Novel multi-core neutral optical cable connector

An optical cable connector and connector technology, which is applied in the coupling of optical waveguides, etc., can solve the problems of ceramic sleeves and internal ceramic ferrule end faces that are difficult to clean, connectors are scrapped, and are easy to break, so as to improve the performance of optical transmission , increase the number of cores, use simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

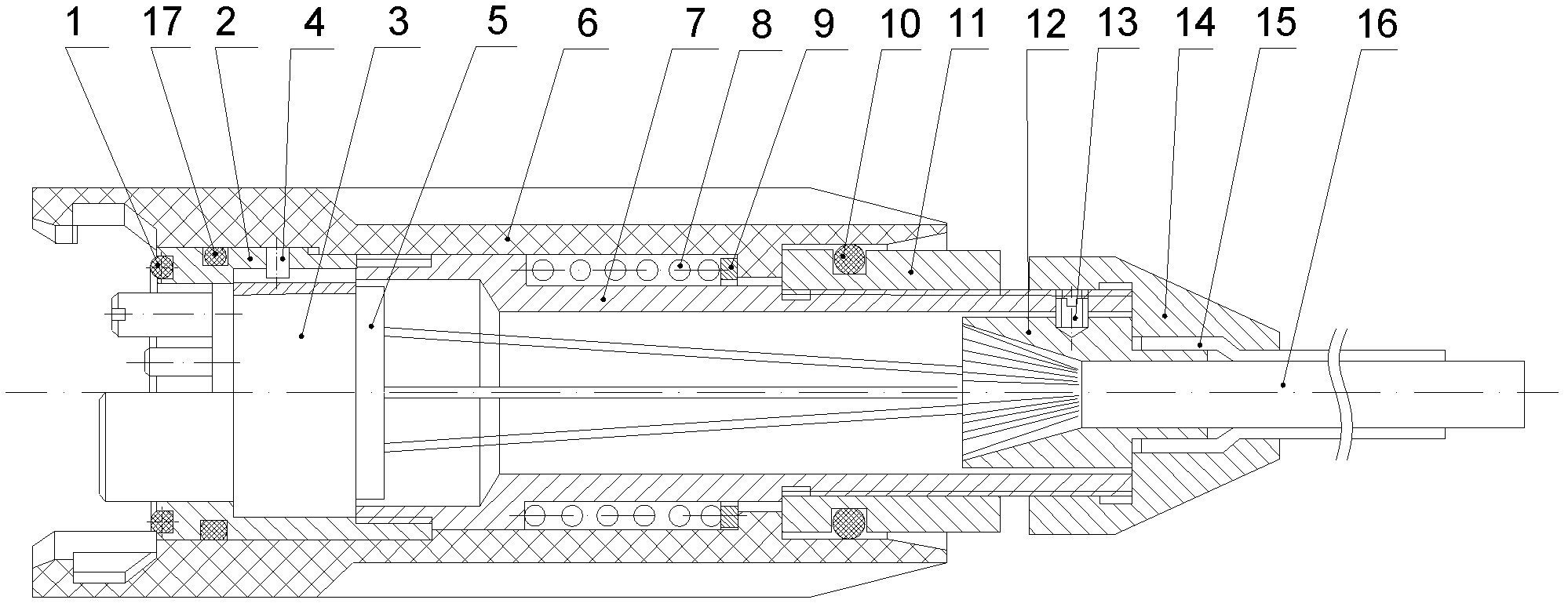

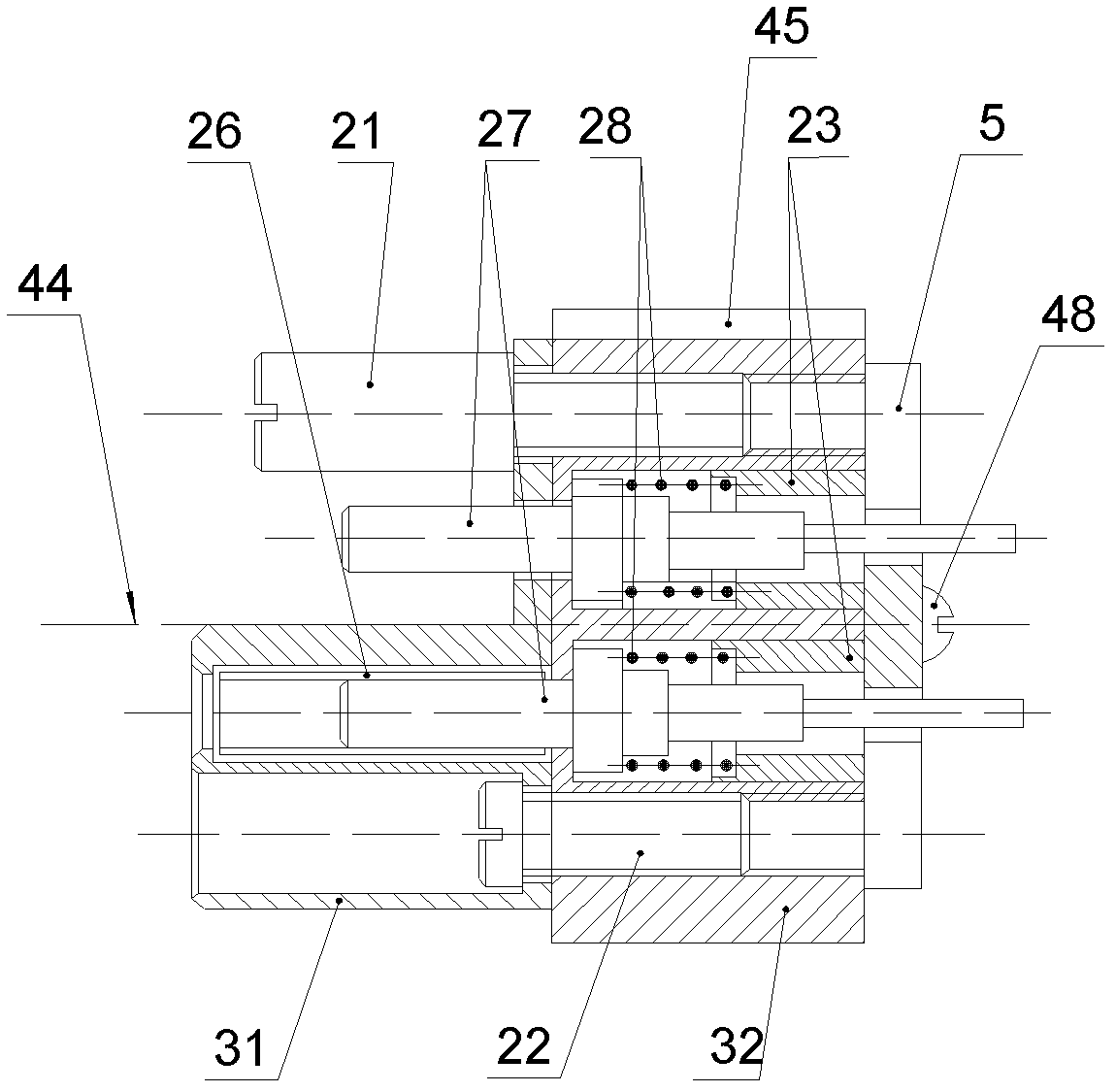

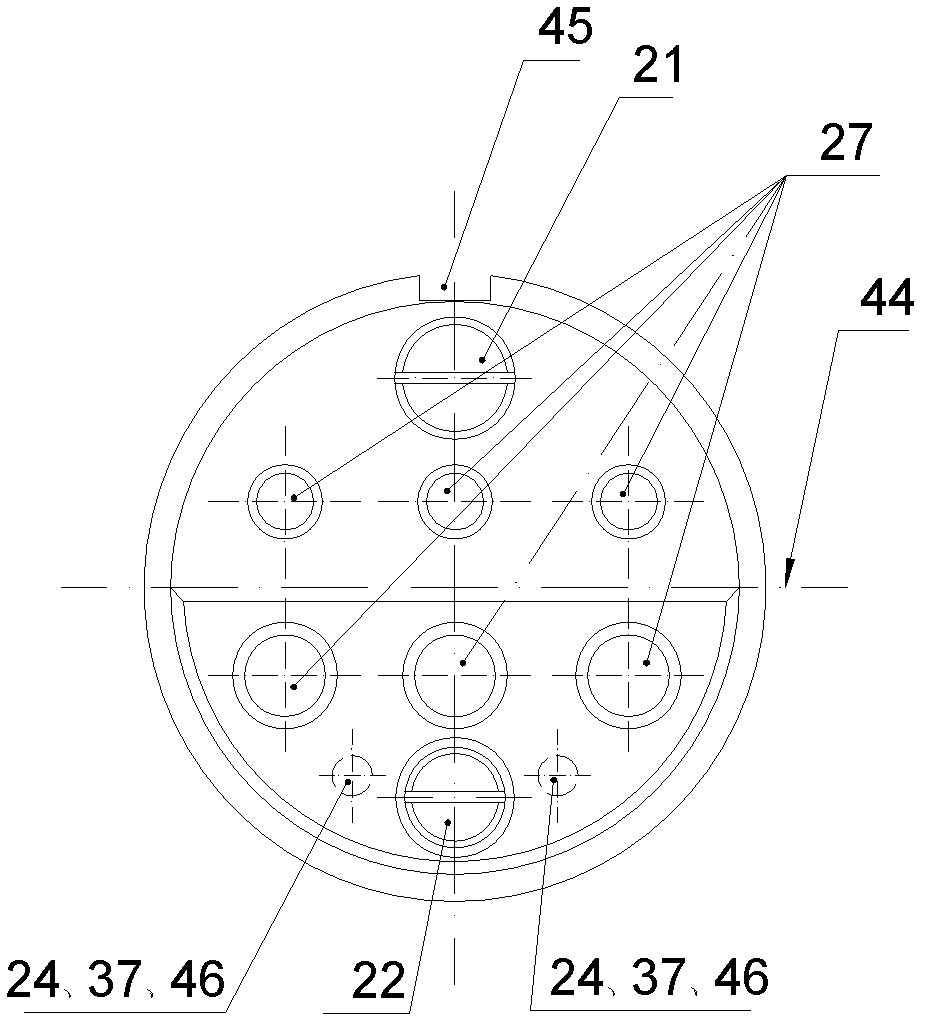

[0030] see figure 1 : the connector of the present invention is a neutral multi-core optical cable connector, that is, any two can be interconnected and matched, and dozens of optical cables can be connected in series. The optical fiber connection positions of the connected two terminal interfaces Always the same, easy to use, especially suitable for fast arbitrary connection between field optical cables. figure 1Among them, 1 is the "O"-shaped sealing ring on the front face of the intermediate sleeve; 2 is the intermediate sleeve; 3 is the base body composed of guide seat 31, pin seat body 32 and pin assembly and other components ; 4 is positioning pin; 5 is pressure plate; 6 is shell; 7 is middle sleeve; 8 is compression spring; 9 is washer; 10 is sealing ring; 11 is locking sleeve; 14 is a tail sleeve, 15 is a protective optical cable spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com