Self-supporting type indoor and outdoor easily-branched optical cable and extrusion mold thereof

An indoor and outdoor easy-to-extrude mold technology, which is applied to other household appliances, optics, light guides, etc., can solve the problems of low laying efficiency and high construction cost, and achieve the effect of improving construction efficiency, reducing construction cost and increasing the number of cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

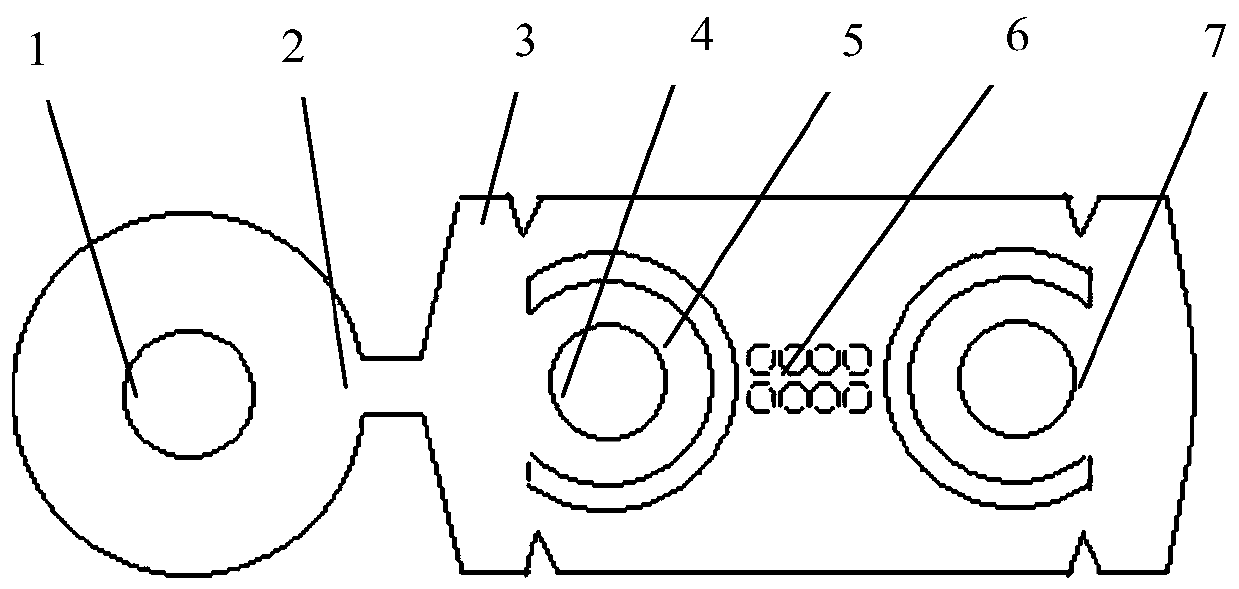

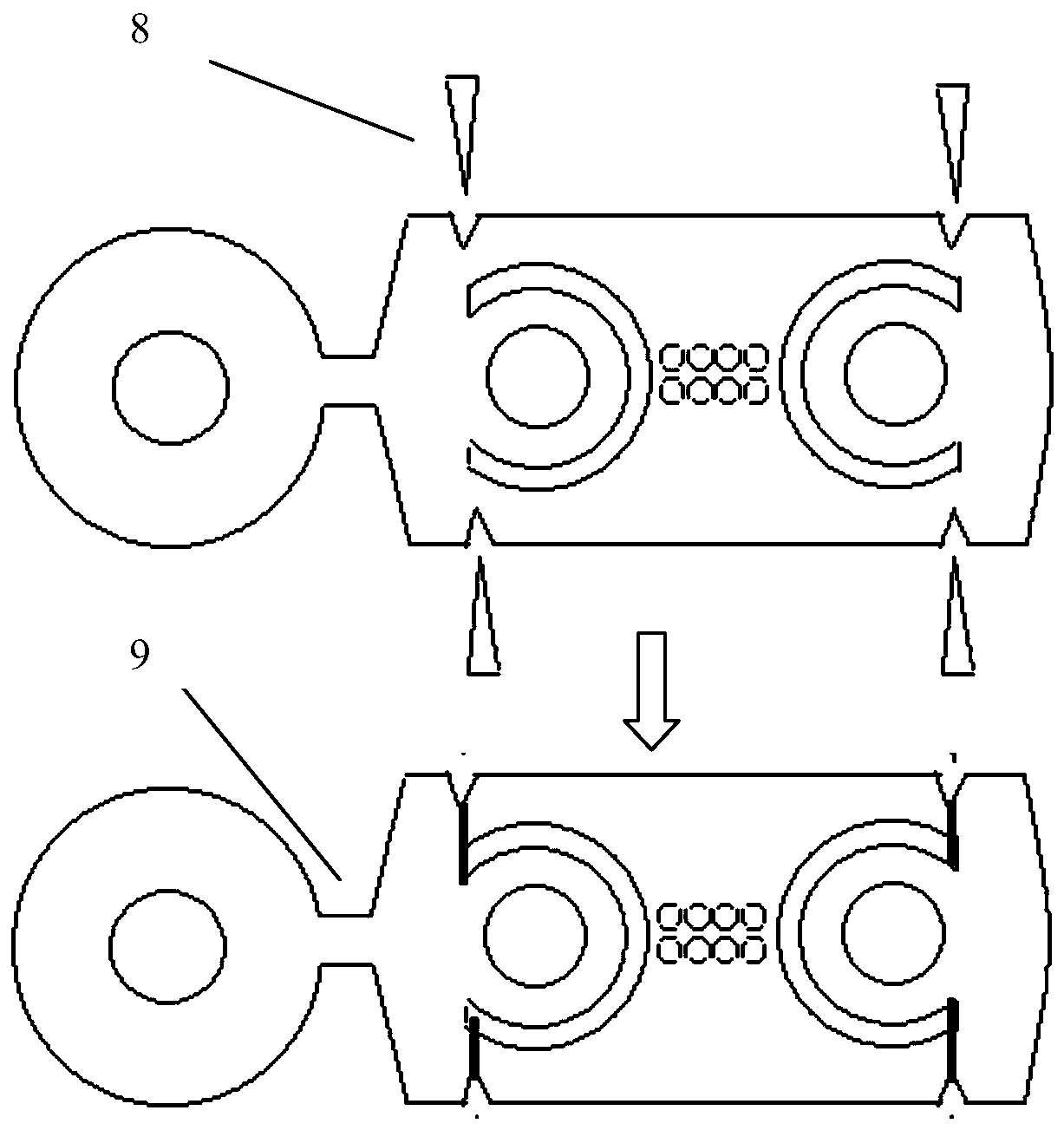

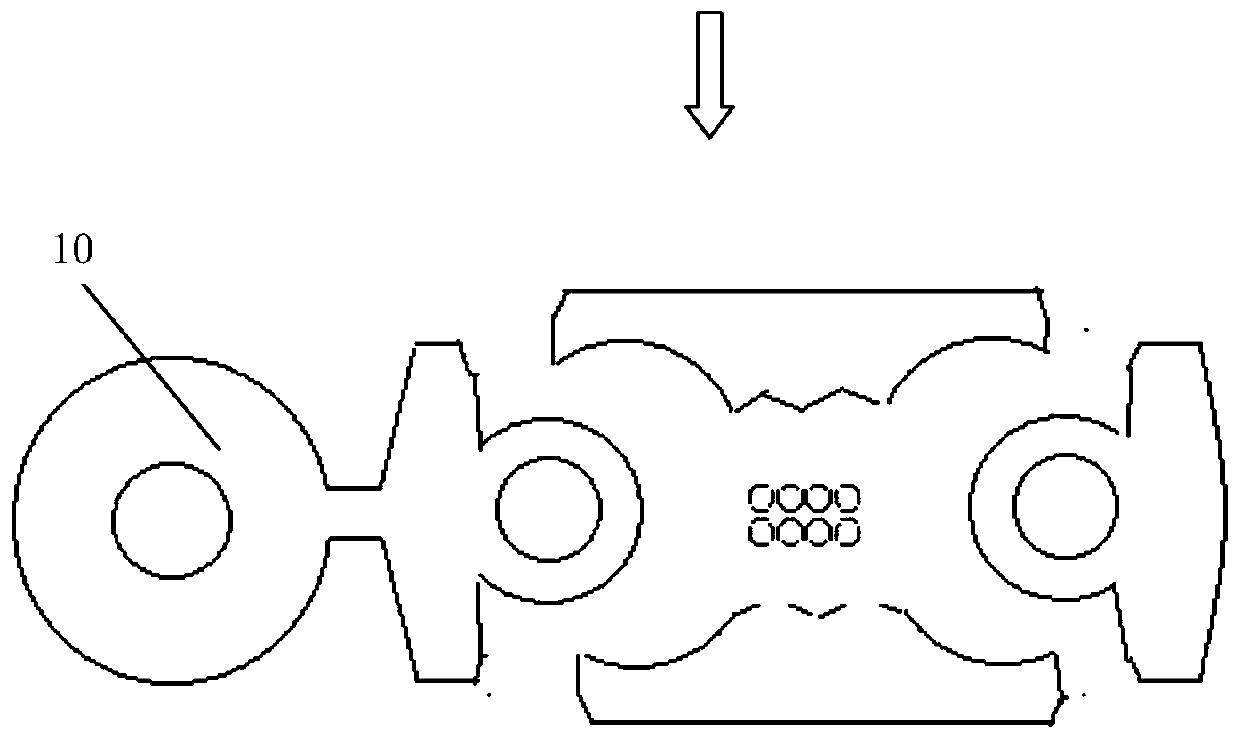

[0032] like figure 1 As shown, it is the structural diagram of the self-supporting indoor and outdoor easy-to-branch optical cable. The optical cable structure consists of metal reinforcement 1, suspension neck 2, V-shaped groove 3, metal reinforcement 4, C-shaped gap 5, tight-buffered optical fiber 6, and outer sheath 7 composed together. Among them, a pair of relatively distributed C-shaped gaps 5 are arranged in the outer sheath 7, a tight sleeve optical fiber 6 is arranged between a pair of relatively distributed C-shaped gaps 5, and a metal reinforcement 4 is arranged in the C-shaped gap 5; the outer sheath One end of the sleeve 7 is provided with a hanging neck 2, and a metal reinf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com