Graphene-containing cast iron inoculant and preparation method and using method thereof

An inoculant and graphene technology, which is applied in the field of cast iron inoculants, can solve the problems of large amount of inoculant added, the inability to use a large amount of recycled material, and the high content of Si in the recycled material, so as to prolong the inoculation recession time, good inoculation effect, and the added amount little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

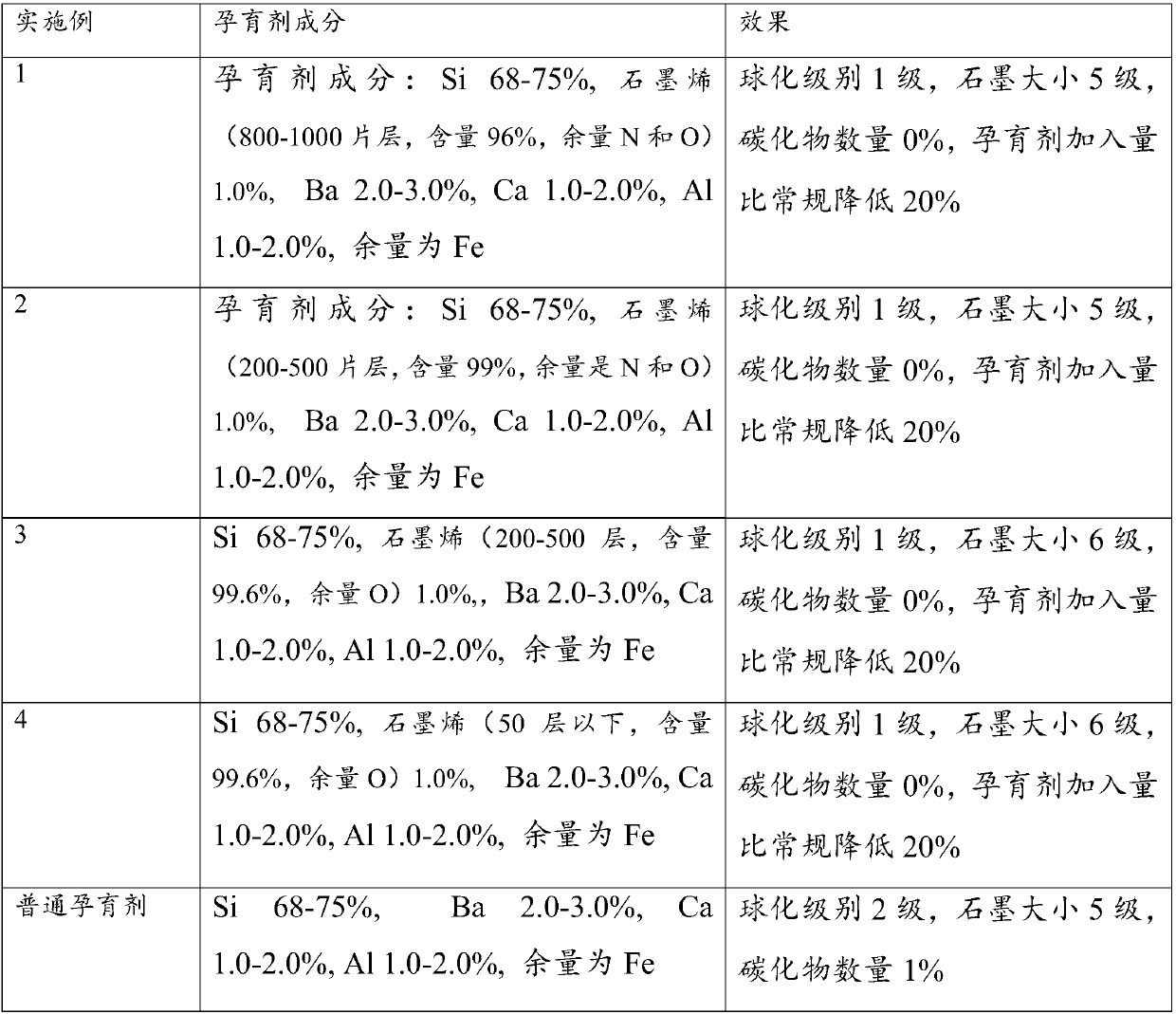

Examples

preparation example Construction

[0044] There are no special restrictions on the preparation method of the graphene. For example, a micromechanical exfoliation method, an epitaxial growth method, a chemical vapor deposition CVD method, a graphene oxide reduction method, etc. can be used. Graphene oxide (ie, graphene oxide) can be obtained by using strong oxidizing agents such as concentrated sulfuric acid, concentrated nitric acid, potassium permanganate and other graphite oxide. The reduced graphene oxide (ie, reduced graphene oxide) can be obtained by reducing the graphene oxide. There is no particular limitation on the reduction method, and hydrazine reduction method, sodium borohydride reduction method, 4C hydrothermal reduction method, etc. can be used. It should be noted that the oxygen content of graphene oxide is usually above 10% (weight percentage), and the graphene mentioned in this specification does not include such graphene oxide.

[0045] The inventor found that by including graphene in the cast i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com