Copper-containing ultra-low carbon bainite steel and preparation method thereof

A carbon bainite steel and bainite technology, which is applied in the field of copper-containing ultra-low carbon bainite steel and its preparation, can solve the problems of large performance fluctuations and narrow production windows, and achieve excellent welding performance and simple composition , good toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

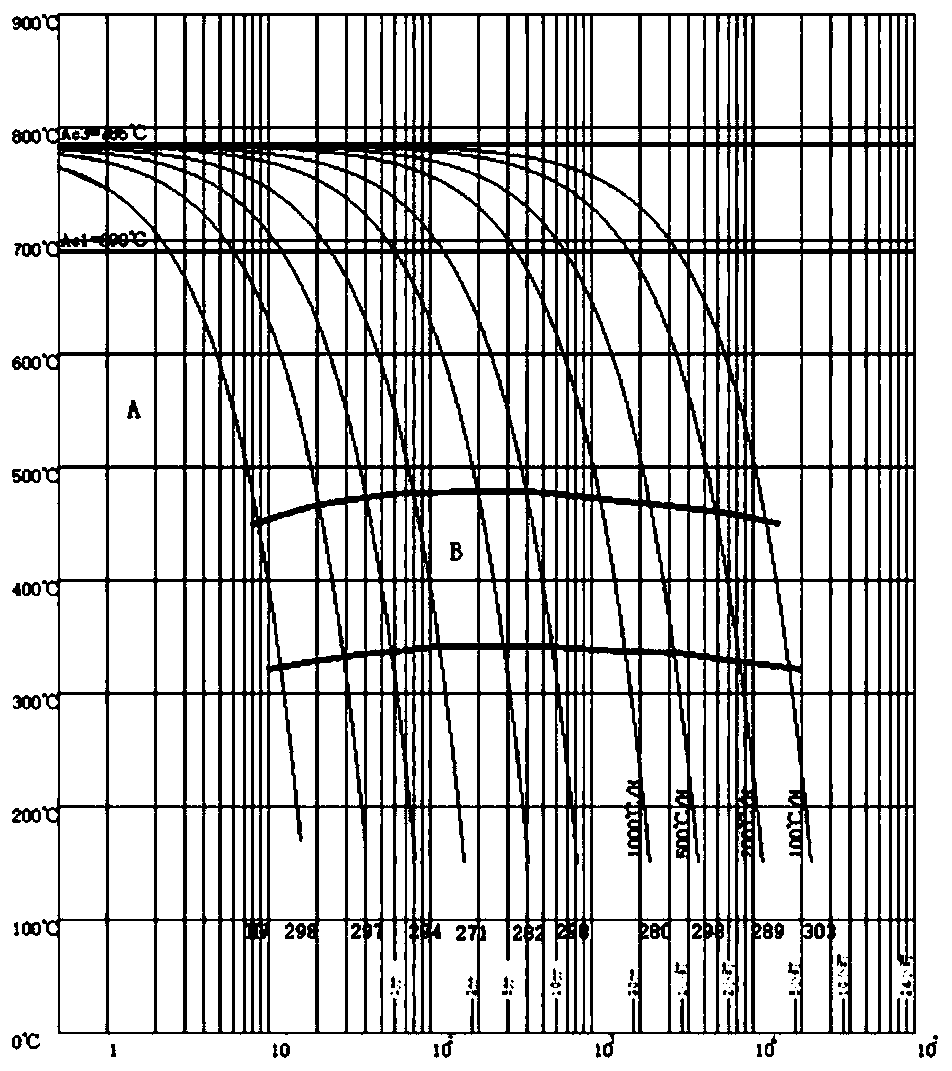

[0048] The invention provides a preparation method of copper-containing ultra-low carbon bainite steel, which uses a heating furnace for heating and smelting, and continuous casting or mold casting for casting. Such as figure 1 As shown, within the cooling rate range in the CCT curve, the bainite steel prepared by the present invention has only passed through the bainite phase region without the ferrite phase region, and the ultra-low carbon bainite steel prepared by the method provided by the invention The body steel can obtain pure bainite structure in a wide cooling rate range, and the bainite platform is wide. Above-mentioned preparation method comprises the following steps:

[0049] Step 1: heating and forging the steel ingot to obtain a steel billet;

[0050] The forging heating temperature is 1180°C-1200°C, the starting forging temperature is 1150°C-1160°C, and the final forging temperature is >850°C to obtain a billet. If the forging temperature is too high, it is e...

Embodiment 1

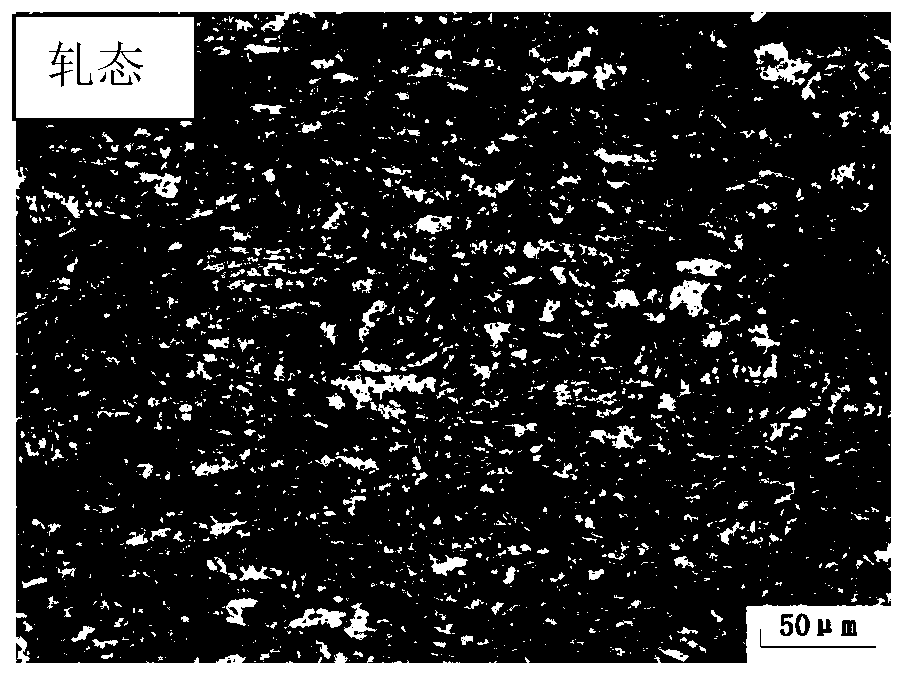

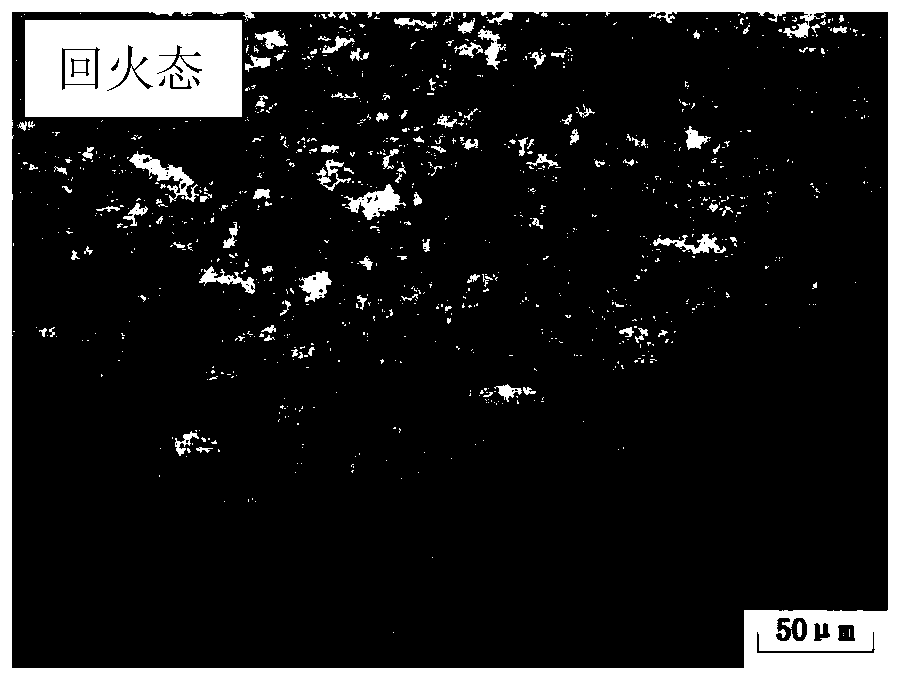

[0064] Such as figure 2 As shown, the chemical composition and content of copper-containing ultra-low carbon bainite steel are: C: 0.010%, Mn: 1.27%, Mo: 1.56%, Nb: 0.03%, Ni: 3.10%, Cr: 0.50%, B: 0.0010%, Cu: 1.43%, and the balance is iron and unavoidable impurities. Its preparation method comprises the following steps:

[0065] Step 1: heating and forging the steel ingot with the above composition to obtain a steel billet;

[0066] The forging heating temperature is 1180°C, the starting forging temperature is 1150°C, and the final forging temperature is 880°C to obtain a billet.

[0067] Step 2: putting the billet obtained in step 1 into a heating furnace for heating;

[0068] The heating temperature is 1180°C, and the heating time is 2h.

[0069] Step 3: Rough rolling and finishing rolling of the heated billet;

[0070] The steel billet is rolled. In the rolling process, there are 2 rough rolling passes, the deformation of the first pass is 25.1%, the deformation of t...

Embodiment 2

[0077] The chemical composition and content of copper-containing ultra-low carbon bainite steel are: C: 0.021%, Mn: 0.80%, Mo: 1.50%, Nb: 0.056%, Ni: 3.00%, Cr: 0.40%, B: 0.0017 %, Cu: 1.40%, and the rest are iron and unavoidable impurities. Its preparation method comprises the following steps:

[0078] Step 1: heating and forging the steel ingot to obtain a steel billet;

[0079] The forging heating temperature was 1185°C, the starting forging temperature was 1155°C, and the final forging temperature was 900°C to obtain a billet.

[0080] Step 2: putting the billet obtained in step 1 into a heating furnace for heating;

[0081] The heating temperature is 1200°C, and the heating time is 2h.

[0082] Step 3: Rough rolling and finishing rolling of the heated billet;

[0083] Rough rolling and finish rolling are carried out on the billet. There are 2 passes of rough rolling, the deformation of the first pass is 25.3%, the deformation of the second pass is 24.2%, and the cumul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com