Square silicon core production equipment and manufacturing technology thereof

A technology of production equipment and silicon core, applied in the direction of manufacturing tools, stone processing equipment, fine working devices, etc., can solve the problems of increased labor intensity, difficult automatic control, and high operator requirements, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

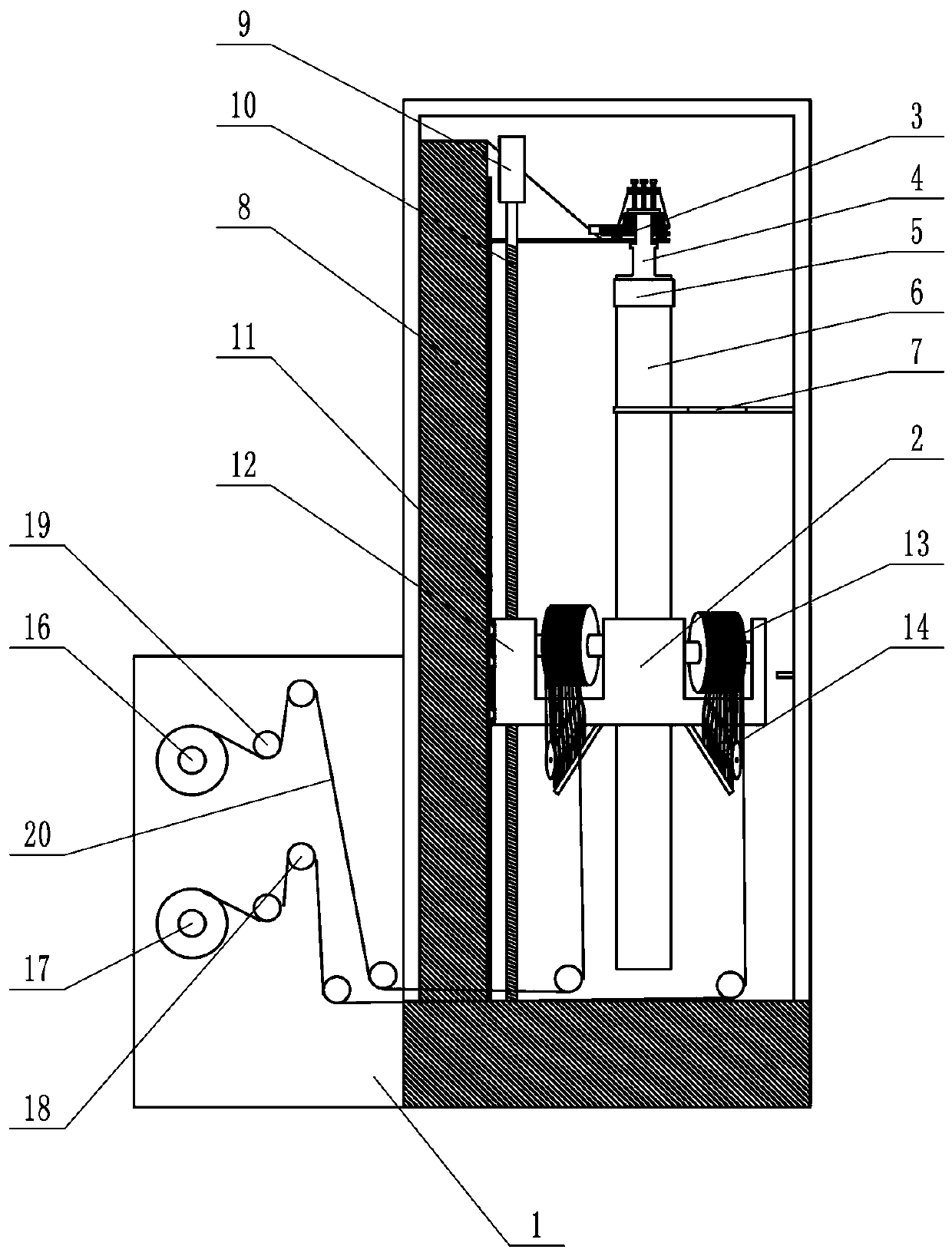

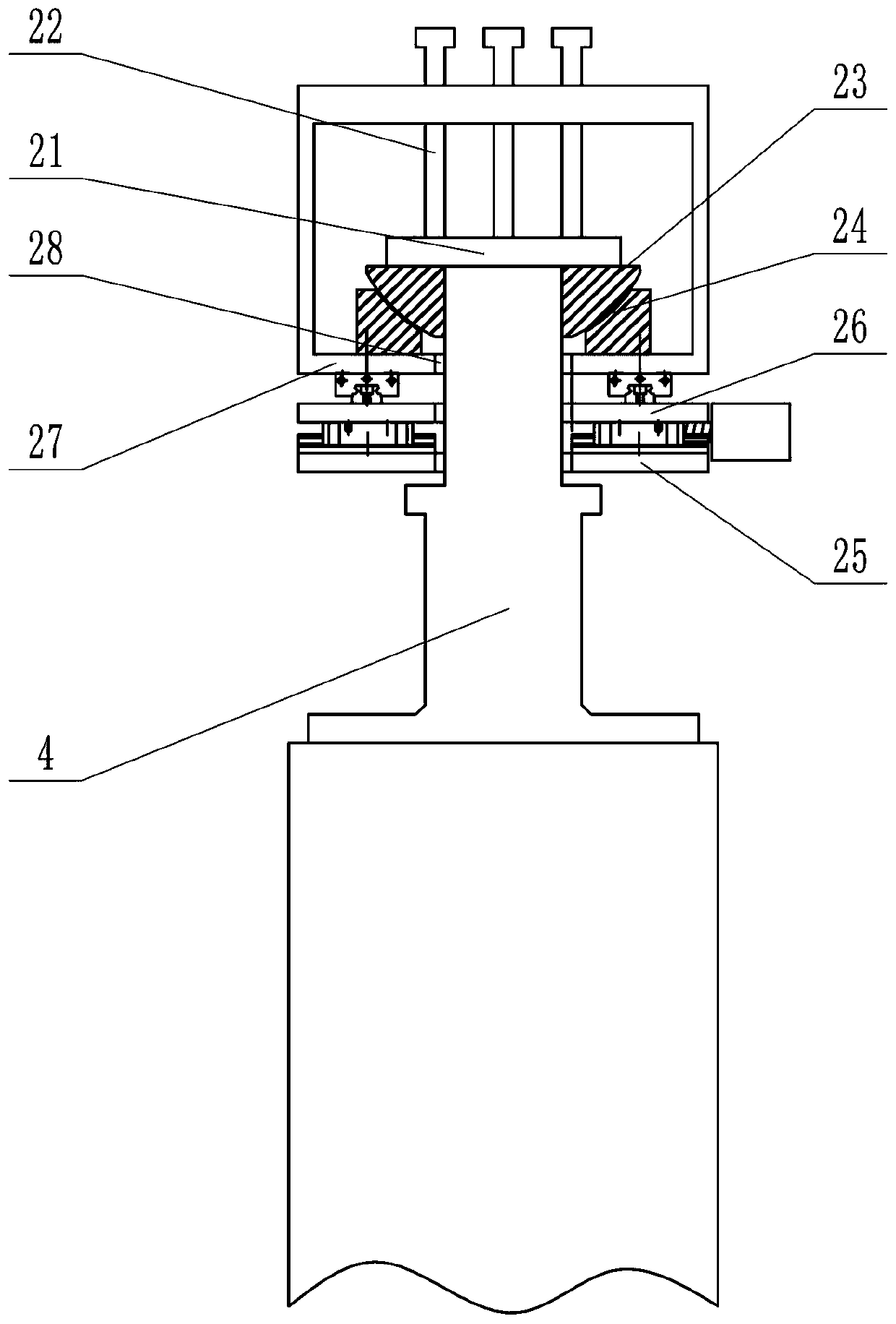

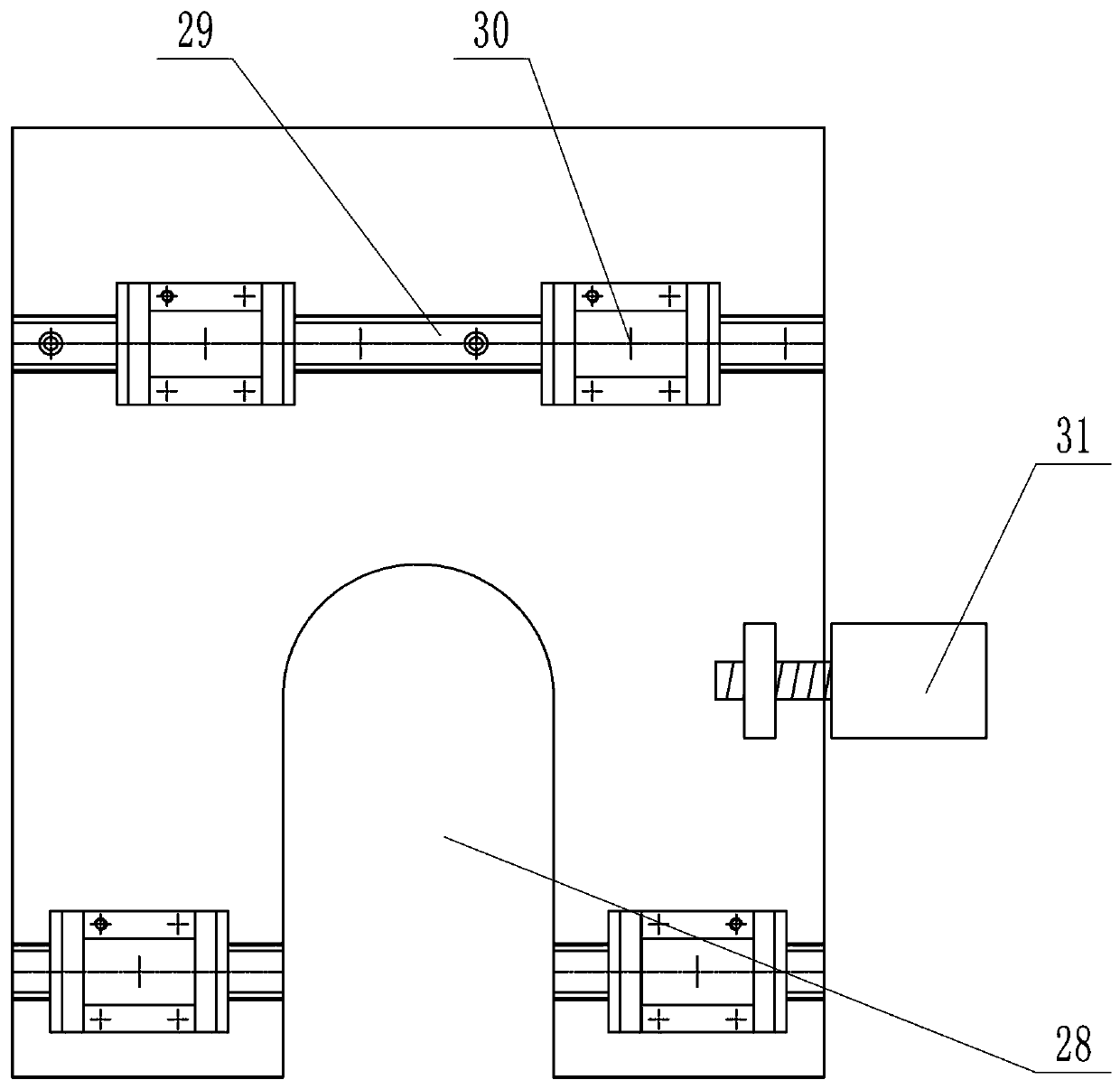

[0047] Such as Figure 1-6 As shown, a square silicon core production equipment includes a frame 1, a cutting head 2 is installed on the frame 1, the cutting head 2 includes a fixing seat, a cutting hole is opened in the middle of the fixing seat, and 4 holes are evenly distributed on the fixing seat. Or 6 suspension frames 14, on the suspension frame, roller 13 is rotated and installed, and take-up wheel 17, pay-off wheel 16, transition wheel one 19, cutting steel wire 20, transition wheel two 18 are installed on the frame 1, and cutting steel wire is according to 20 Second winding pay-off wheel, transition wheel 19, roller 13, transition wheel 2, take-up wheel, the cutting steel wire on the roller forms a cutting wire net 15, 4 rollers form a square grid or adopt 6 roller machines to form a triangular net The frame is equipped with a lifting drive mechanism for driving the cutting head to lift. The lifting drive mechanism includes a bearing column 8 installed on the frame al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com