All-dielectric large-core-number high-density micro pipeline wiring cable and manufacturing method thereof

A large-core, high-density technology, applied in the field of all-dielectric, large-core, high-density micro-pipe wiring optical cables and its production, can solve problems such as easy damage to fingers and optical fibers, increased bending performance attenuation, and impact on customer service activation. Achieve the effect of strong pipeline passing capacity, small frictional resistance and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

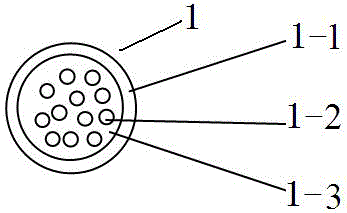

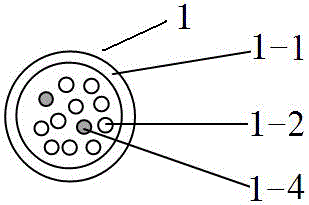

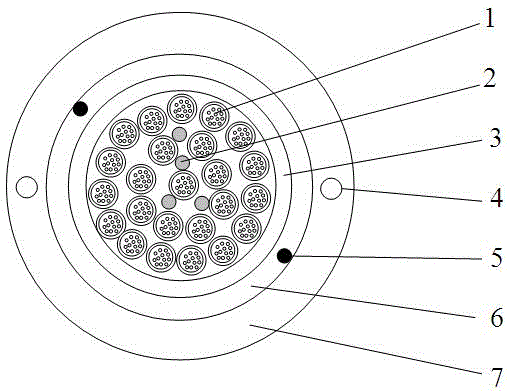

[0086] The production method of all-dielectric large-core high-density micro-duct optical cable takes 288 cores as an example.

[0087] According to the design of the 288-core optical fiber cable, the water-blocking optical fiber micro-tube unit is designed as 12 cores / tube*24 pieces.

[0088] 1. Production of 12-core water-blocking fiber optic microtube unit 1

[0089] Prepare the 12-core optical fiber pay-off rack, test and adjust the pay-off tension of each optical fiber pay-off rack, and uniformly adjust it to 40-50g. The pay-off tension of each optical fiber must be strictly consistent;

[0090] Pass the optical fiber through the ceramic wire hole of the stranding equipment, pass through the fiber paste heating chamber, and pull it to the machine head to fix it;

[0091] Select the 12-core water-blocking fiber microtube mold for extrusion, the sheath material is thermoplastic elastomer polyolefin material, adjust the inner and outer concentricity, outer diameter, and wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com