Nodular cast iron rare-earth magnesium silicon nodularizer

A technology of nodular cast iron and rare earth magnesium, which is applied in the field of nodular cast iron, can solve the problems of difficult control of the spheroidization process, unstable spheroidization quality, and reduced magnesium absorption rate, so as to achieve good spheroidization effect, reduce inclusions, and reduce magnesium loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

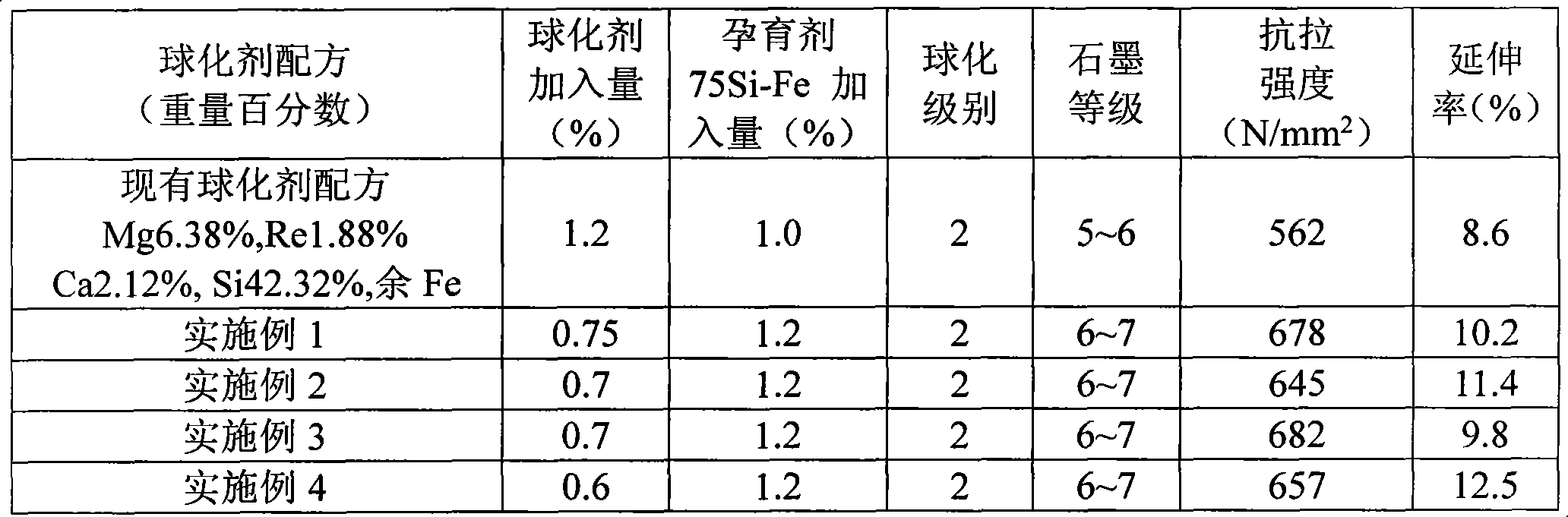

Embodiment 1

[0018] The rare earth magnesium silicon spheroidizer for ductile iron of the present invention, wherein the weight percentage of Mg is 12%, the weight percentage of Re is 2%, the weight percentage of Si is 45%, the weight percentage of Ca is 3.5%, and the weight percentage of Ba The percentage is 1.0%, the weight percentage of Mn is 3%, the weight percentage of C is 0.5%, the content of Al is less than 1.5%, and the balance is Fe.

[0019] The above elements are crushed into granules according to the conventional fusion method, and the nodularizer of rare earth magnesium silicon for ductile iron is obtained.

Embodiment 2

[0021] The rare earth magnesium silicon spheroidizer for ductile iron of the present invention, wherein the weight percentage of Mg is 13%, the weight percentage of Re is 1.5%, the weight percentage of Si is 44%, the weight percentage of Ca is 4.5%, and the weight percentage of Ba The percentage is 1.0%, the weight percentage of Mn is 2.0%, the weight percentage of C is 1.5%, the content of Al is less than 1.5%, and the balance is Fe.

[0022] The above elements are crushed into granules according to the conventional fusion method, and the nodularizer of rare earth magnesium silicon for ductile iron is obtained.

Embodiment 3

[0024] The rare earth magnesium silicon spheroidizer for ductile iron of the present invention, wherein the weight percentage of Mg is 14%, the weight percentage of Re is 1.0%, the weight percentage of Si is 42%, the weight percentage of Ca is 4%, and the weight percentage of Ba The percentage is 0.8%, the weight percentage of Mn is 5%, the weight percentage of C is 0.5%, the content of Al is less than 1.5%, and the balance is Fe.

[0025] The above elements are crushed into granules according to the conventional fusion method, and the nodularizer of rare earth magnesium silicon for ductile iron is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com