Preparation method of high-manganese low-chromium alloy wear-resisting ball

A chromium alloy and wear-resistant ball technology, which is applied in the field of preparation of high-manganese and low-chromium alloy wear-resistant balls, can solve the problems of aggravating columnar grains, and achieve the effects of refining grains, increasing hardness, and increasing elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

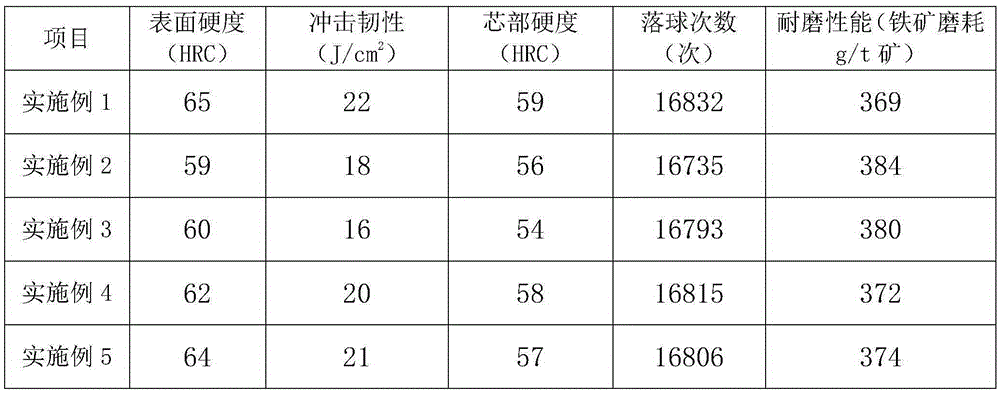

Examples

Embodiment 1

[0032] A preparation method of a high manganese low chromium alloy wear-resistant ball, comprising the steps of:

[0033] S1. Melt carbon powder, chromium ingot, manganese ingot, molybdenum ingot, nickel ingot, vanadium ingot, borax, antimony sand, tungsten ingot, niobium ingot, tantalum ingot, phosphorus powder and sulfur powder to obtain alloy liquid, and use argon gas The tank is sprayed with argon gas, and the nano-modifier is evenly dispersed in the alloy liquid for modification treatment;

[0034] S2. Add a covering agent to the surface of the modified alloy liquid in S1, calm down, refine and desulfurize, deoxidize, and detect. The alloy liquid includes the following components by weight percentage: C: 2.60%; Cr: 2.0%; Mn: 12.30%; Mo: 0.34%; Ni: 0.35%; Rare Earth: 0.17%; V: 0.23%; B: 0.20%; Ti: 0.06%; 0.04%; S: 0.03%, the balance is iron and unavoidable impurities;

[0035] S3. The alloy liquid obtained in S2 is poured, casted, cleaned, and the casting is obtained. Th...

Embodiment 2

[0040] A preparation method of a high manganese low chromium alloy wear-resistant ball, comprising the steps of:

[0041] S1. Melt carbon powder, chromium ingot, manganese ingot, molybdenum ingot, nickel ingot, vanadium ingot, borax, antimony sand, tungsten ingot, niobium ingot, tantalum ingot, phosphorus powder and sulfur powder to obtain alloy liquid, and use argon gas The tank is sprayed with argon gas, and the nano-modifier is evenly dispersed in the alloy liquid for modification treatment;

[0042] S2. Add a covering agent to the surface of the modified alloy liquid in S1, calm down, refine and desulfurize, deoxidize, and detect. The alloy liquid includes the following components by weight percentage: C: 2.5%; Cr: 2.5%; Mn: 11.20%; Mo: 0.4%; Ni: 0.3%; Rare Earth: 0.20%; V: 0.15%; B: 0.3%; 0.06%, the balance is iron and unavoidable impurities;

[0043] S3, pouring the alloy liquid obtained in S2, casting and cleaning to obtain castings, preheating the castings at 950°C f...

Embodiment 3

[0048] A preparation method of a high manganese low chromium alloy wear-resistant ball, comprising the steps of:

[0049] S1. Melt carbon powder, chromium ingot, manganese ingot, molybdenum ingot, nickel ingot, vanadium ingot, borax, antimony sand, tungsten ingot, niobium ingot, tantalum ingot, phosphorus powder and sulfur powder to obtain alloy liquid, and use argon gas The tank is sprayed with argon gas, and the nano-modifier is evenly dispersed in the alloy liquid for modification treatment;

[0050] S2. Add a covering agent to the surface of the modified alloy liquid in S1, calm down, refine desulfurization, deoxidize, and detect. The alloy liquid includes the following components by weight percentage: C: 2.8%; Cr: 1.5%; Mn: 13.50%; Mo: 0.3%; Ni: 0.4%; Rare Earth: 0.15%; V: 0.30%; B: 0.1%; 0.08%, the balance is iron and unavoidable impurities;

[0051] S3, pouring the alloy liquid obtained in S2, casting and cleaning, to obtain castings, preheating the castings at 1050°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com