Conductive wear-resistant quakeproof equipment pad material and preparation method thereof

A foot pad and equipment technology, applied in the field of conductive wear-resistant shockproof equipment foot pad material and its preparation, can solve the problems of low tensile strength and elongation at break, achieve high flexibility and improve the effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

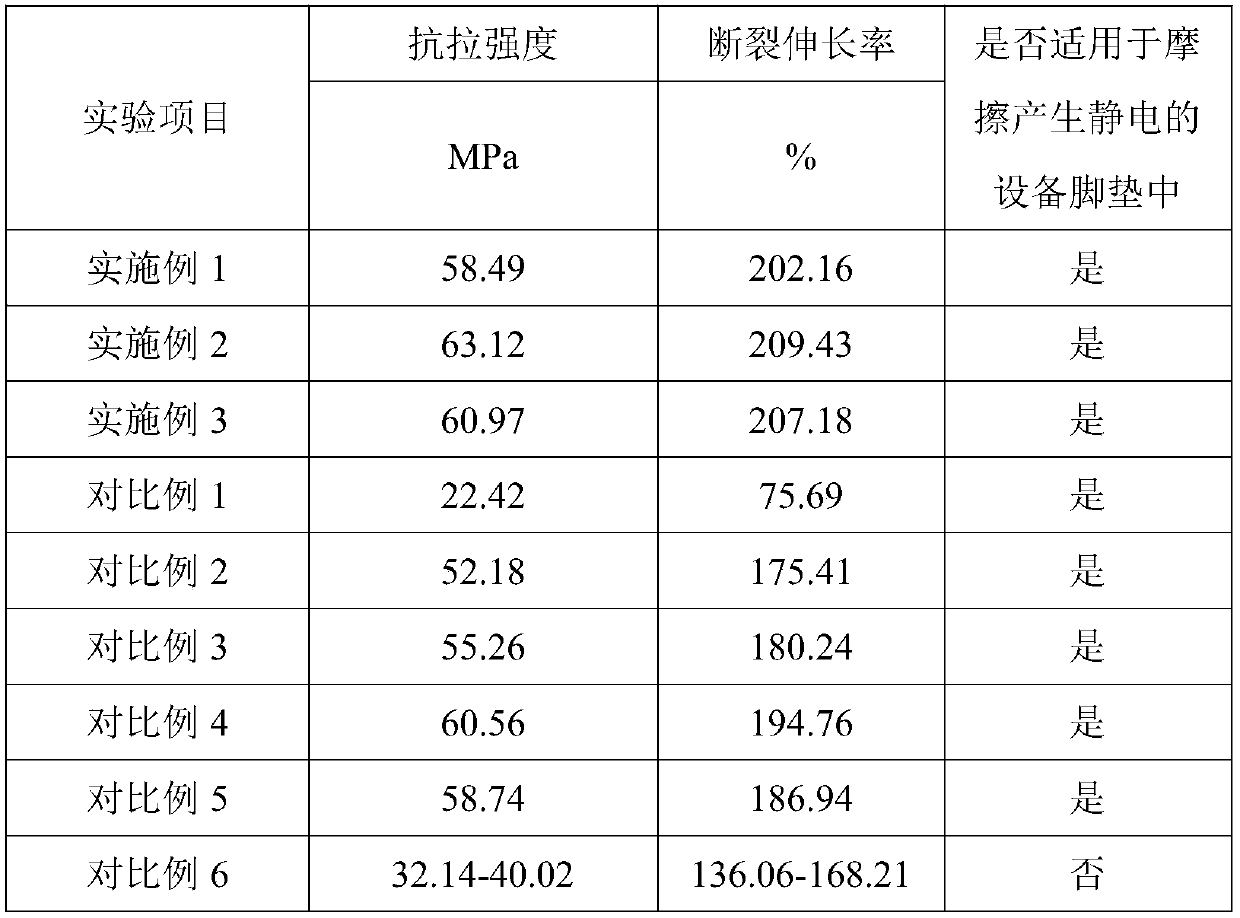

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the foot pad material of the conductive wear-resistant and shockproof equipment comprises the following steps:

[0032] S1: Weigh each component according to parts by weight;

[0033] S2: Put each component in a high-speed mixer, stir and mix evenly, the condition is that the stirring speed is 1000-2000r / min, the stirring temperature is 65-68°C, and the stirring time is 0.2-0.3h;

[0034] S3: Send the material mixed in step S2 into a high-shear twin-screw extruder for extrusion, cool after extrusion, and cut into pellets to obtain a conductive wear-resistant shockproof equipment foot pad material, wherein the extrusion conditions are divided into four zones , the temperature is 165-195°C in the first zone, 195-215°C in the second zone, 205-215°C in the third zone, and 215-225°C in the fourth zone.

Embodiment 1

[0037] A conductive, wear-resistant and anti-shock equipment foot pad material, including the following raw materials in mass percentage: TPU65%, stainless steel powder 24.5%, graphite powder 5%, antioxidant 1%, dispersant 1%, nano-titanium carbide 1.5%, nano-carbide Tungsten 1%, tungsten silicide 0.6%, tungsten powder 0.4%;

[0038] The TPU is thermoplastic polyurethane elastomer rubber, specifically TPU German Bayer 2790A;

[0039] The antioxidant is antioxidant 1010;

[0040] Described dispersant is barium stearate;

[0041] The preparation method of the foot pad material of the conductive wear-resistant and shockproof equipment comprises the following steps:

[0042] S1: Weigh each component according to parts by weight;

[0043] S2: Put each component in a high-speed mixer, stir and mix evenly, the condition is that the stirring speed is 1000r / min, the stirring temperature is 65°C, and the stirring time is 0.3h;

[0044] S3: Send the material mixed in step S2 into a h...

Embodiment 2

[0046] A conductive, wear-resistant and shock-proof equipment foot pad material, including the following raw materials in mass percentage: TPU70.5%, stainless steel powder 21.2%, graphite powder 4.2%, antioxidant 0.8%, dispersant 0.7%, nano-titanium carbide 1%, Nano tungsten carbide 0.8%, tungsten silicide 0.5%, tungsten powder 0.3%;

[0047] The TPU is thermoplastic polyurethane elastomer rubber, specifically TPU German Bayer 2790A;

[0048] The antioxidant is antioxidant 1010;

[0049] Described dispersant is barium stearate;

[0050] The preparation method of the foot pad material of the conductive wear-resistant and shockproof equipment comprises the following steps:

[0051] S1: Weigh each component according to parts by weight;

[0052] S2: Put each component in a high-speed mixer, stir and mix evenly, the condition is that the stirring speed is 1700r / min, the stirring temperature is 66°C, and the stirring time is 0.25h;

[0053] S3: Send the material mixed in step S2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com