Preparing method for rare earth aluminum alloy material good in corrosion-resisting performance

A technology of aluminum alloy material and preparation process, applied in the field of aluminum alloy preparation, can solve the problems of poor corrosion resistance, tensile strength, low elongation at break, etc., and achieve the effect of improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

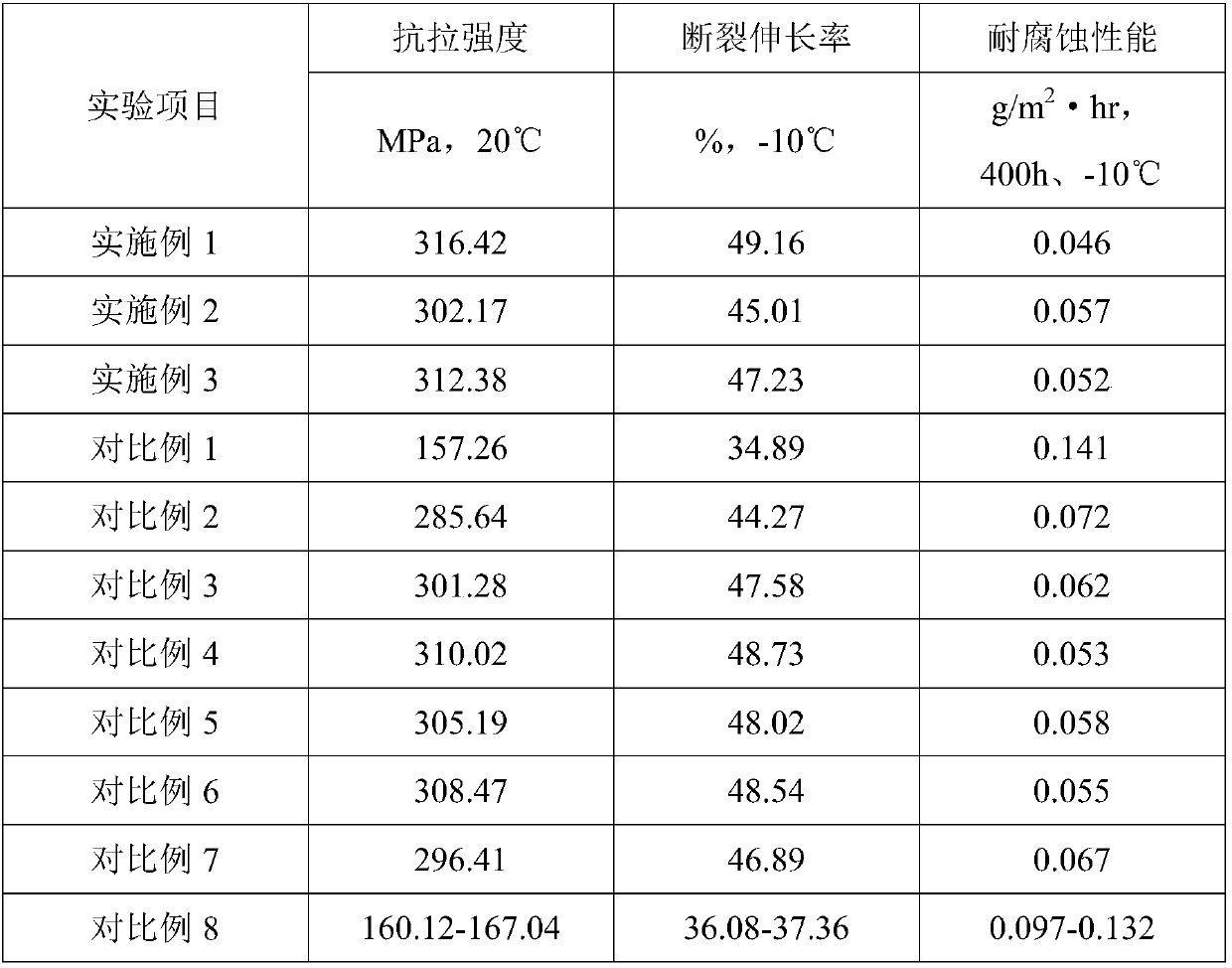

Examples

Embodiment 1

[0035] A rare earth aluminum alloy material with good corrosion resistance, comprising the following raw materials in parts by weight: 1620 parts of aluminum, 16 parts of copper, 7 parts of vanadium, 5 parts of manganese, 7 parts of tin, 2 parts of chromium, and 32 parts of rare earth elements 14 parts of titanium carbide, 10 parts of tungsten carbide, 8 parts of tungsten silicide, 4 parts of tungsten, 18 parts of refining agent, 30 parts of grain refiner;

[0036] The rare earth elements are in parts by weight, including the following raw materials: 8 parts of praseodymium, 4 parts of erbium, 2 parts of samarium, 4 parts of dysprosium, 7 parts of holmium, and 6 parts of yttrium;

[0037] The refining agent includes the following raw materials in parts by weight: 16 parts of sodium chloride, 15 parts of sodium fluoride, 6 parts of graphite, and 5 parts of calcium fluoride;

[0038] The grain refiner includes the following raw materials in parts by weight: 12 parts of aluminum-...

Embodiment 2

[0047] A rare earth aluminum alloy material with good corrosion resistance, comprising the following raw materials in parts by weight: 1200 parts of aluminum, 19 parts of copper, 8 parts of vanadium, 6 parts of manganese, 8 parts of tin, 3 parts of chromium, and 20 parts of rare earth elements 10 parts of titanium carbide, 8 parts of tungsten carbide, 7 parts of tungsten silicide, 3 parts of tungsten, 15 parts of refining agent, 26 parts of grain refiner;

[0048] The rare earth elements are in parts by weight, including the following raw materials: 7 parts of praseodymium, 6 parts of erbium, 1 part of samarium, 5 parts of dysprosium, 5 parts of holmium, and 7 parts of yttrium;

[0049] The refining agent includes the following raw materials in parts by weight: 20 parts of sodium chloride, 8 parts of sodium fluoride, 7 parts of graphite, and 3 parts of calcium fluoride;

[0050] The grain refiner includes the following raw materials in parts by weight: 7 parts of aluminum-sili...

Embodiment 3

[0059] A rare earth aluminum alloy material with good corrosion resistance, comprising the following raw materials in parts by weight: 1850 parts of aluminum, 12 parts of copper, 5 parts of vanadium, 2 parts of manganese, 4 parts of tin, 1 part of chromium, and 38 parts of rare earth elements 15 parts of titanium carbide, 12 parts of tungsten carbide, 9 parts of tungsten silicide, 5 parts of tungsten, 20 parts of refining agent, 35 parts of grain refiner;

[0060] The rare earth elements are in parts by weight, including the following raw materials: 9 parts of praseodymium, 2 parts of erbium, 3 parts of samarium, 3 parts of dysprosium, 8 parts of holmium, and 2 parts of yttrium;

[0061] The refining agent includes the following raw materials in parts by weight: 10 parts of sodium chloride, 16 parts of sodium fluoride, 5 parts of graphite, and 6 parts of calcium fluoride;

[0062] The grain refiner includes the following raw materials in parts by weight: 15 parts of aluminum-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com