Novel metal diffusion bonding technology

A technology of metal diffusion and bonding process, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc. It can solve problems such as increasing bonding pressure, damage to acousto-optic media, and pressure not being too large, so as to achieve reliable bonding , reduce the requirements of physical size, improve the effect of bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

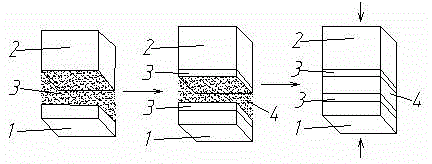

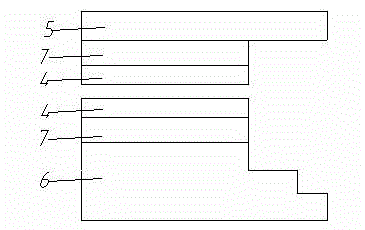

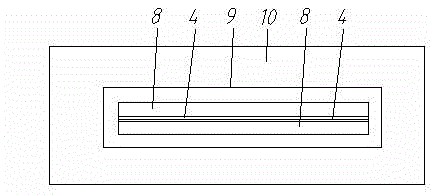

[0030] The novel metal diffusion bonding technique of the present invention, its process step is (can refer to image 3 ),

[0031] 1) Clean the bonding surface of the components to be bonded;

[0032] 2) Deposit the bonding layer metal 4 on the bonding surfaces of the two parts to be bonded 8;

[0033] 3) Encapsulate the two components 8 deposited with the bonding layer metal in a vacuum-sealed soft bag 9, and make the two bonding layer metals fit together according to the bonding requirements;

[0034] 4) Put the vacuum-sealed soft bag 9 enclosing the components to be bonded in a container containing the liquid 10, so that the vacuum-sealed soft bag 9 is surrounded by the liquid 10, and the container is connected to a pressurizing device. When bonding, start the pressurizing device, and the pressure applied by the pressurizing device will act on the part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com