Patents

Literature

132results about How to "Meet the requirements of automated production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

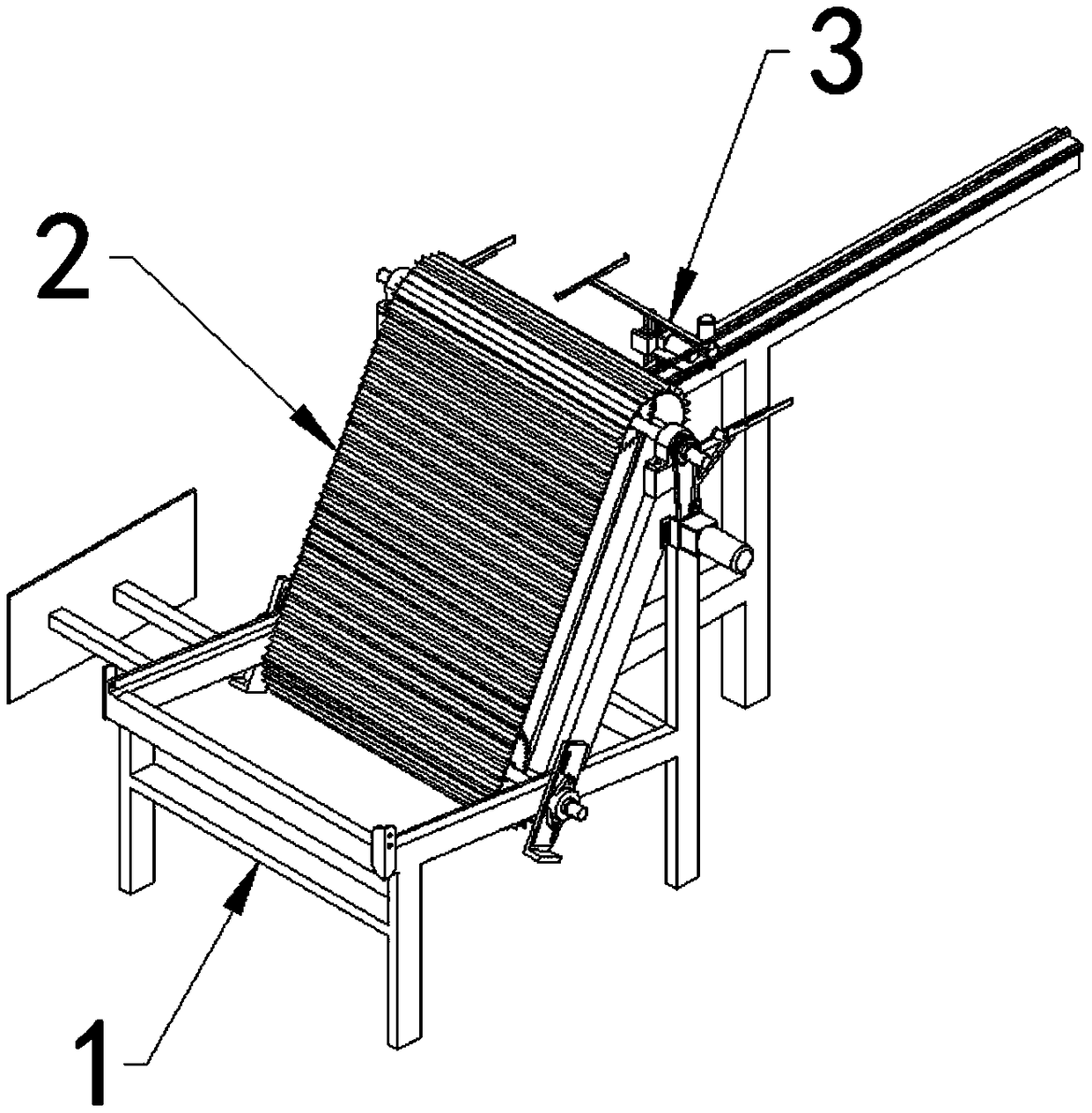

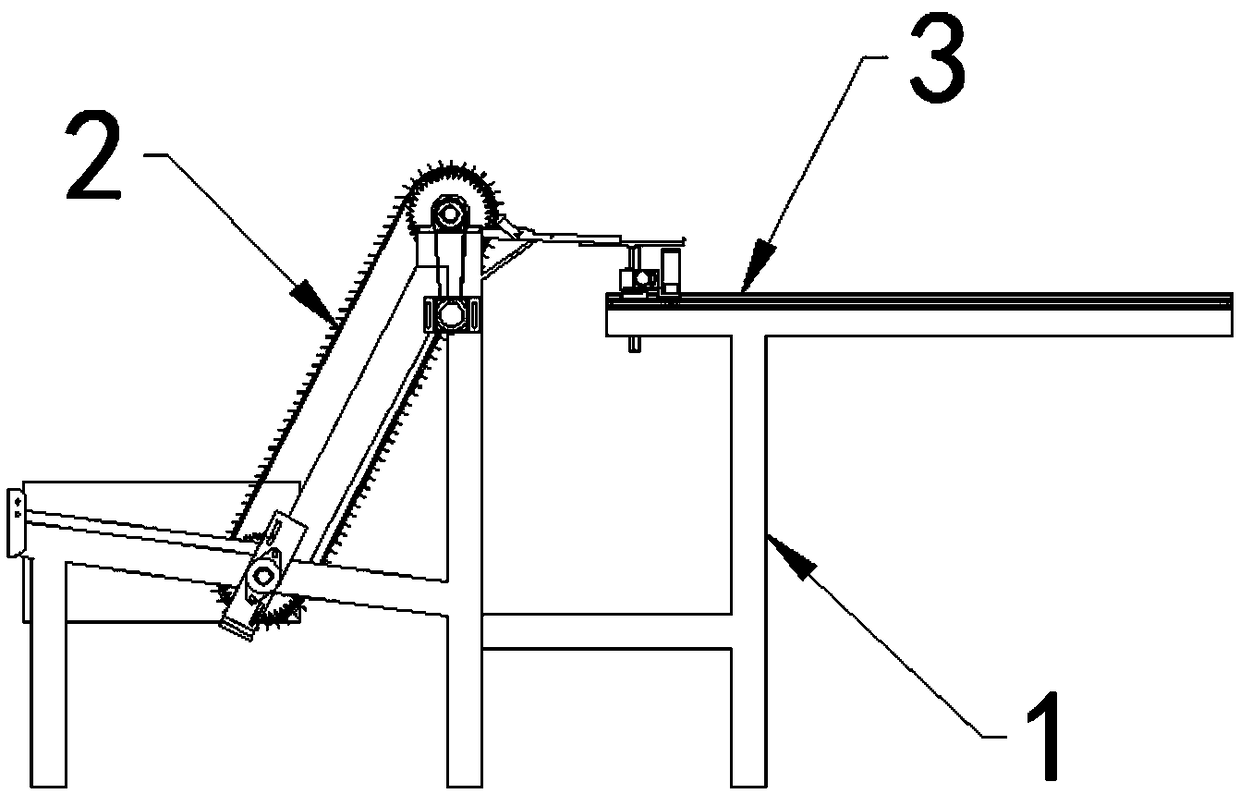

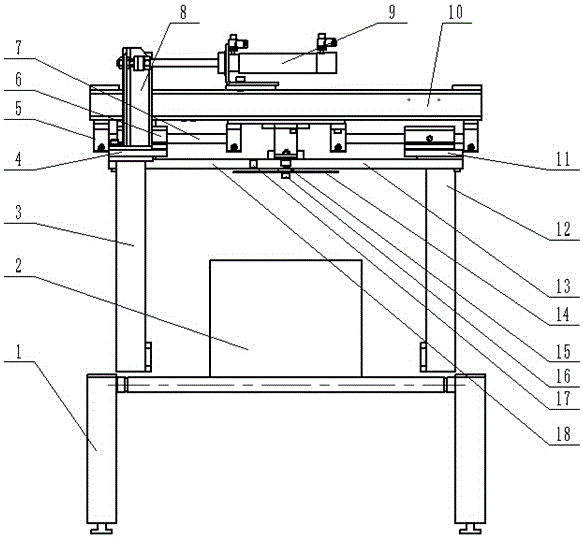

Brick unloading and stacking unit and brick unloading and stacking method for sintered bricks

ActiveCN103552832ASolve bonding problemsReduce labor intensityStacking articlesDe-stacking articlesBrickPalletizer

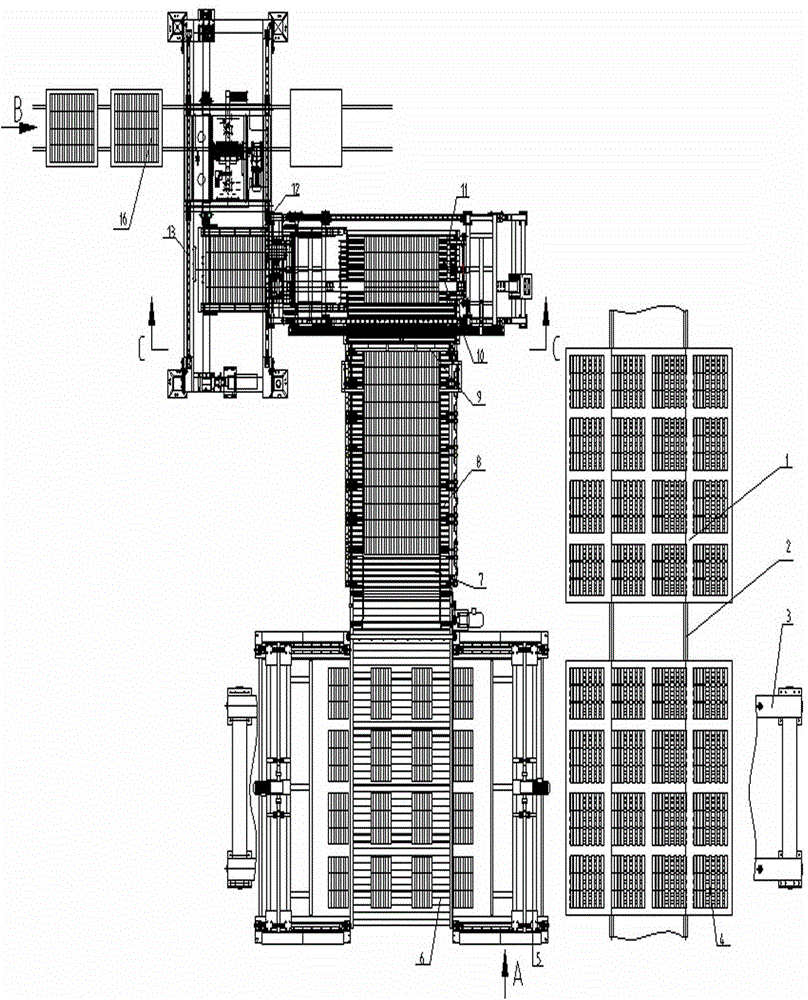

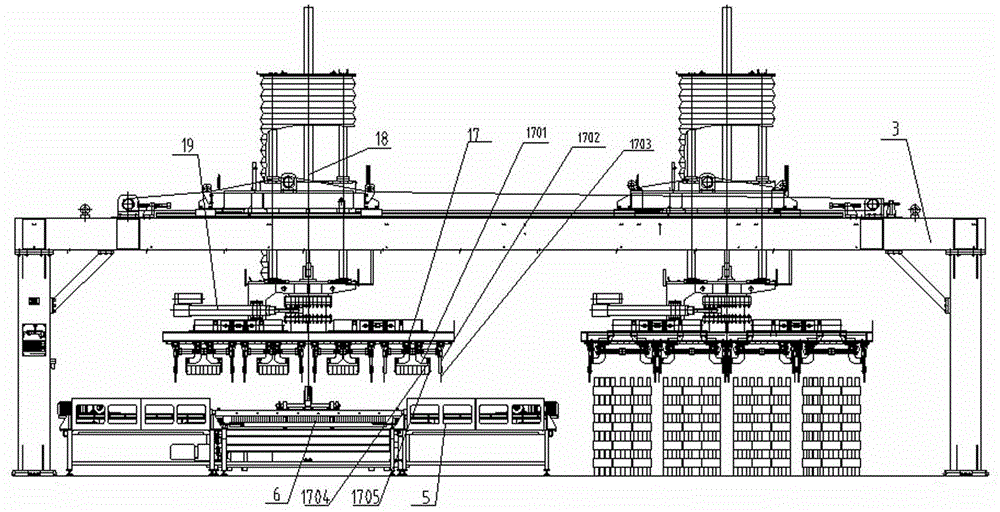

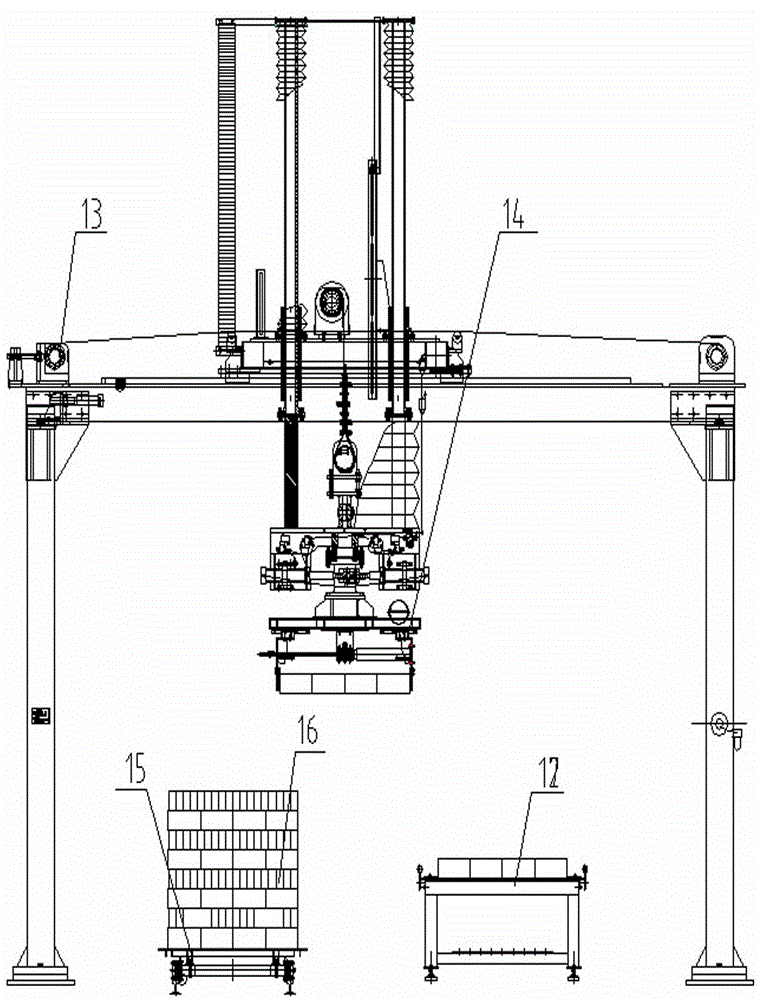

The invention discloses a brick unloading and stacking unit and a brick unloading and stacking method for sintered bricks. The brick unloading and stacking unit comprises a brick unloading machine for unloading the sintered bricks from a kiln car layer by layer and a pushing mechanism for gathering the bricks transversely; a first roller way conveying platform which is connected behind the brick unloading and stacking unit is provided with a brick collimating device capable of gathering the bricks longitudinally; the first roller way conveying platform is used for grouping the bricks and conveying the bricks onto a second roller way conveying platform which is connected with the first roller way conveying platform under the control of a controller; a conveying device for conveying the grouped bricks along a direction vertical to the conveying direction of the first roller way conveying platform forward is arranged above the second roller way conveying platform; a brick gathering platform is arranged at the tail end of the second roller way conveying platform; a stacking machine for stacking the bricks on the brick gathering platform by clamping in groups is arranged above the brick gathering platform. According to the brick unloading and stacking unit, a full mechanical process from unloading to stacking is realized, the problem of bonding caused by deformation of sintered bricks is solved effectively, the requirement of automatic production is met, and the labor force of workers and production cost are greatly reduced.

Owner:洛阳曜辰自动化科技有限公司

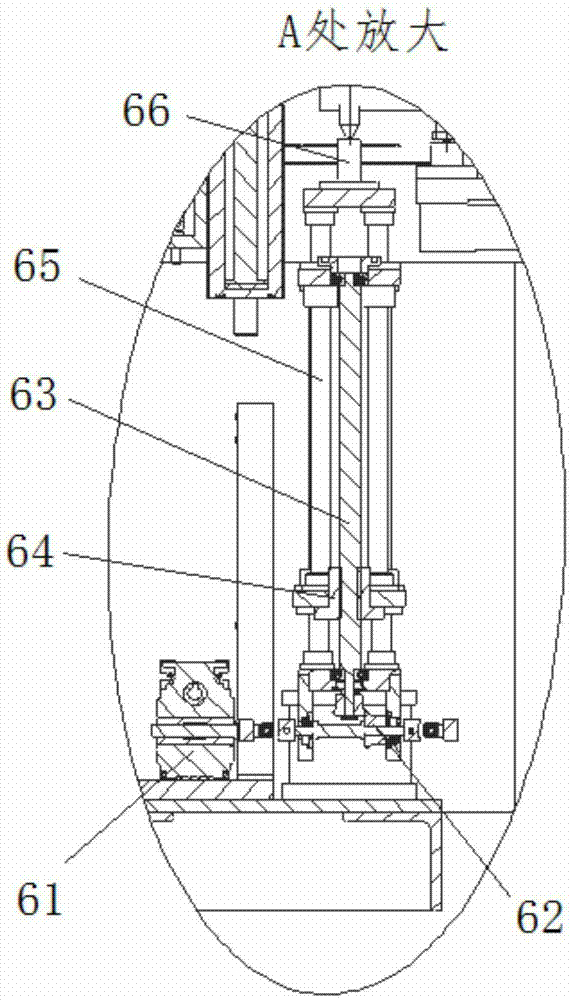

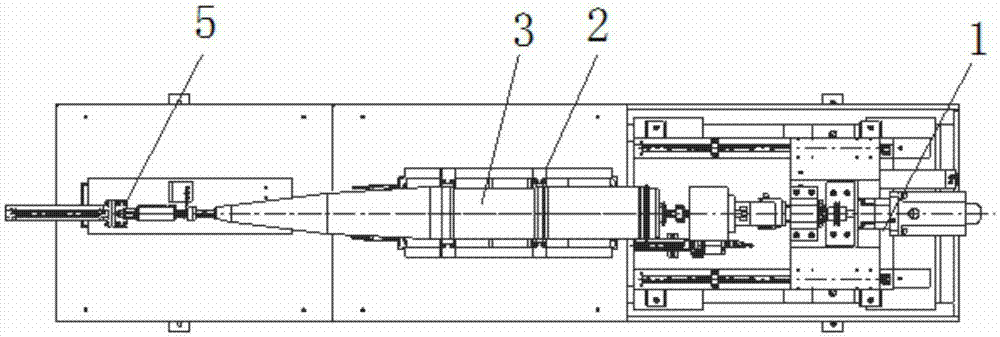

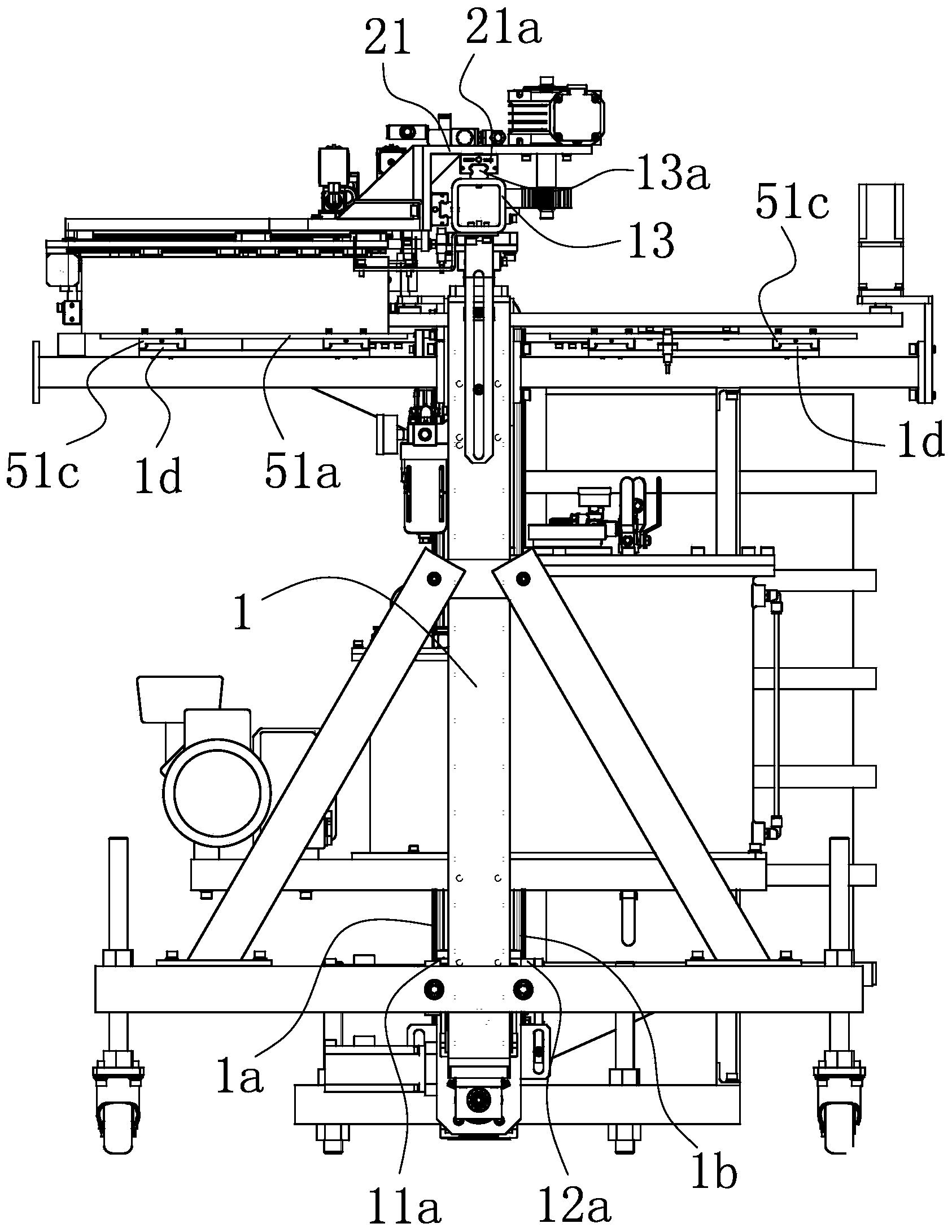

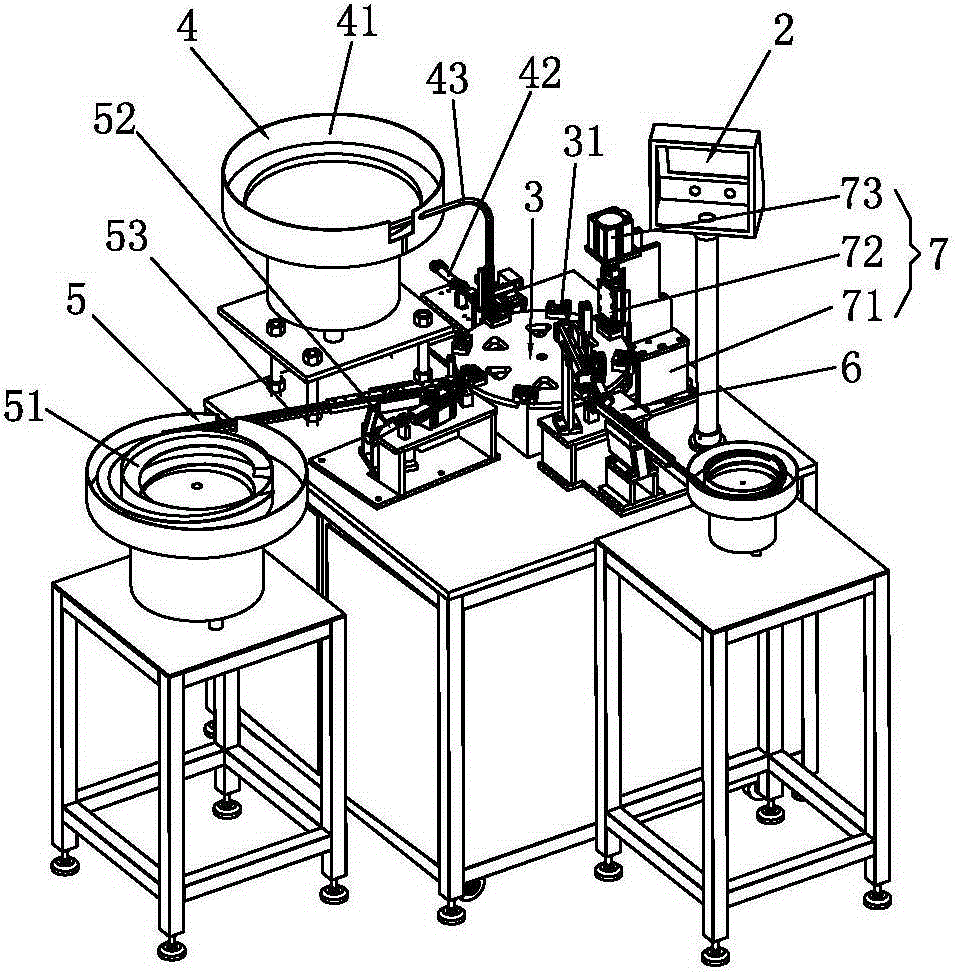

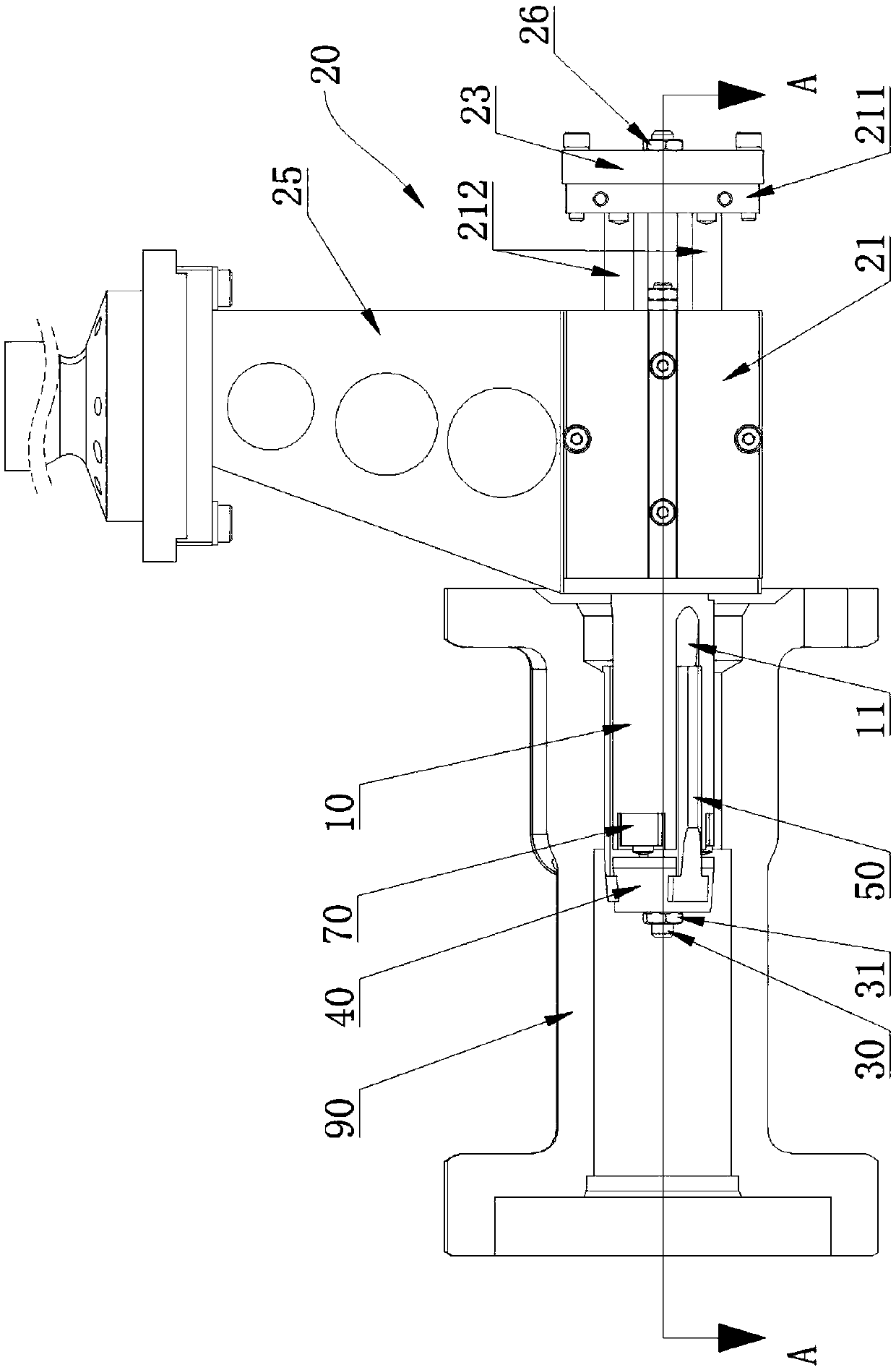

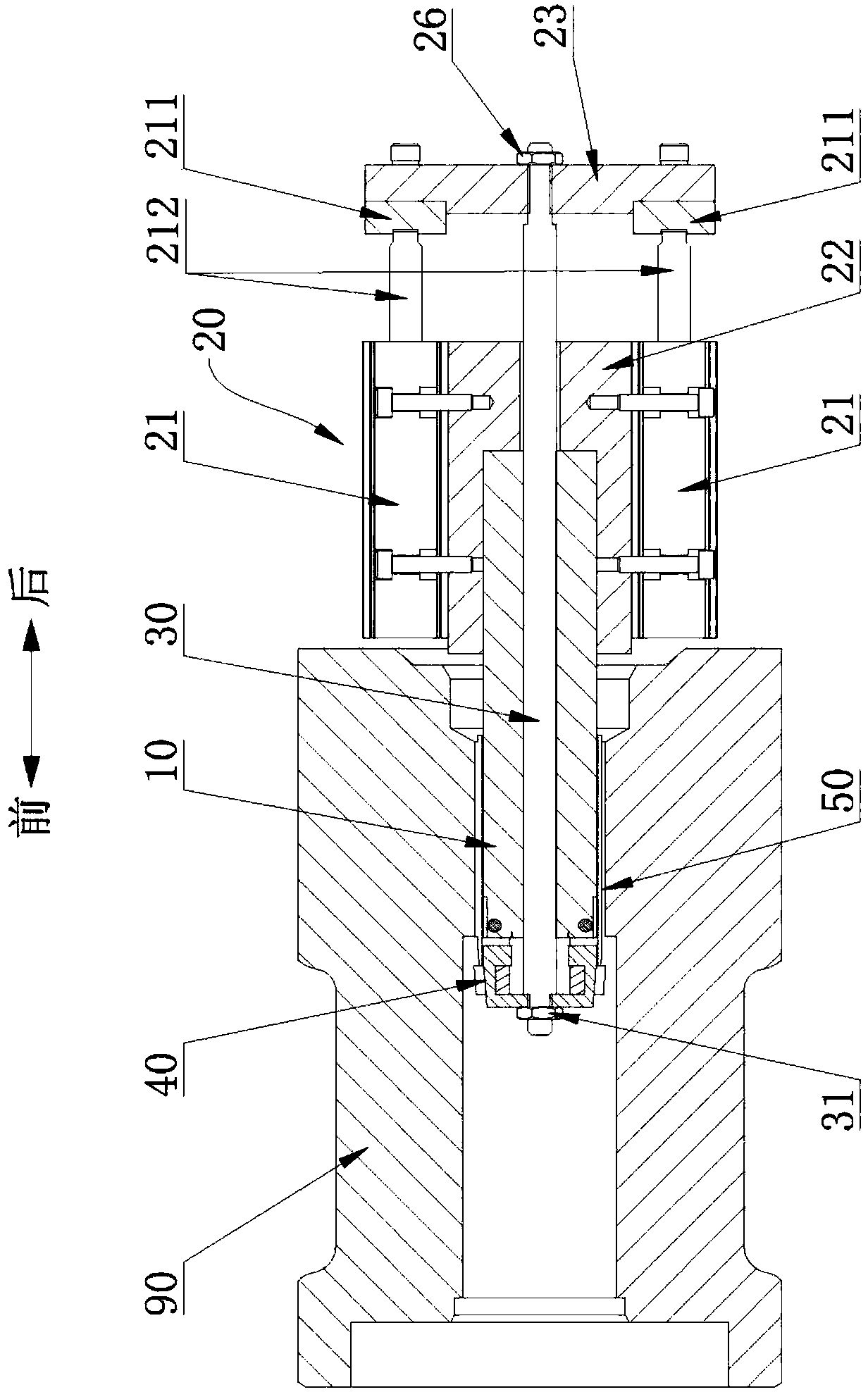

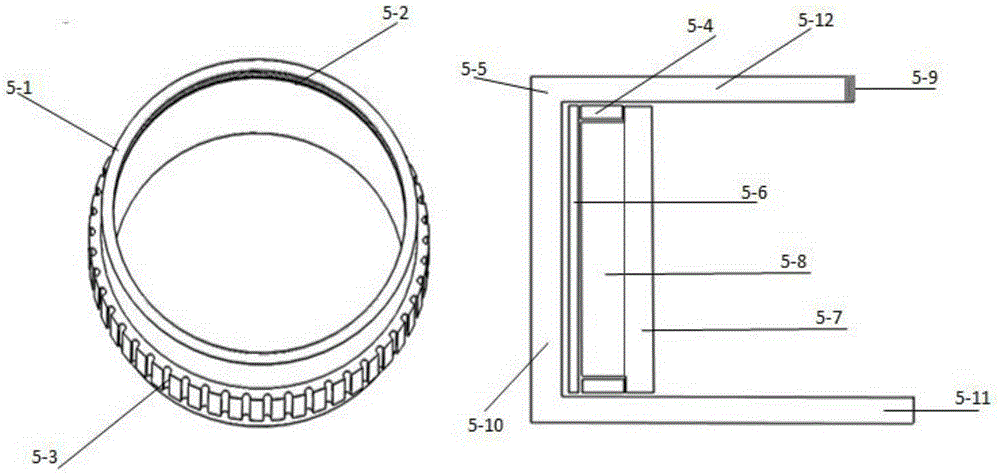

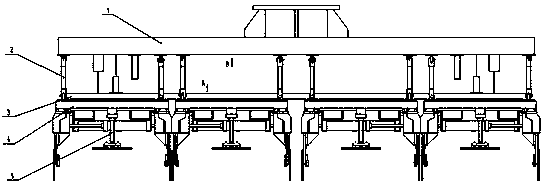

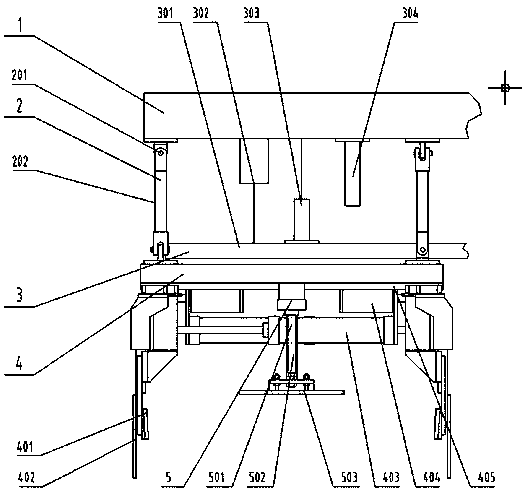

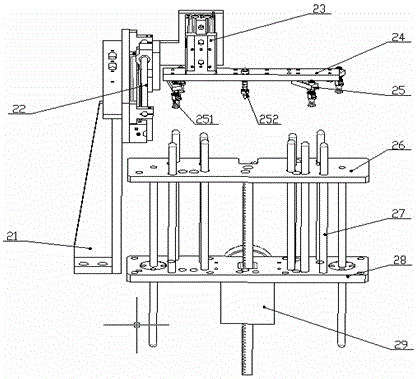

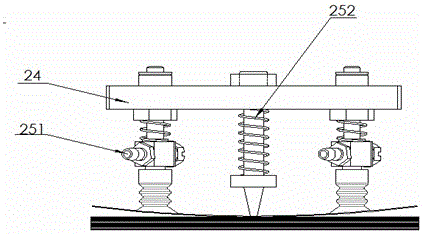

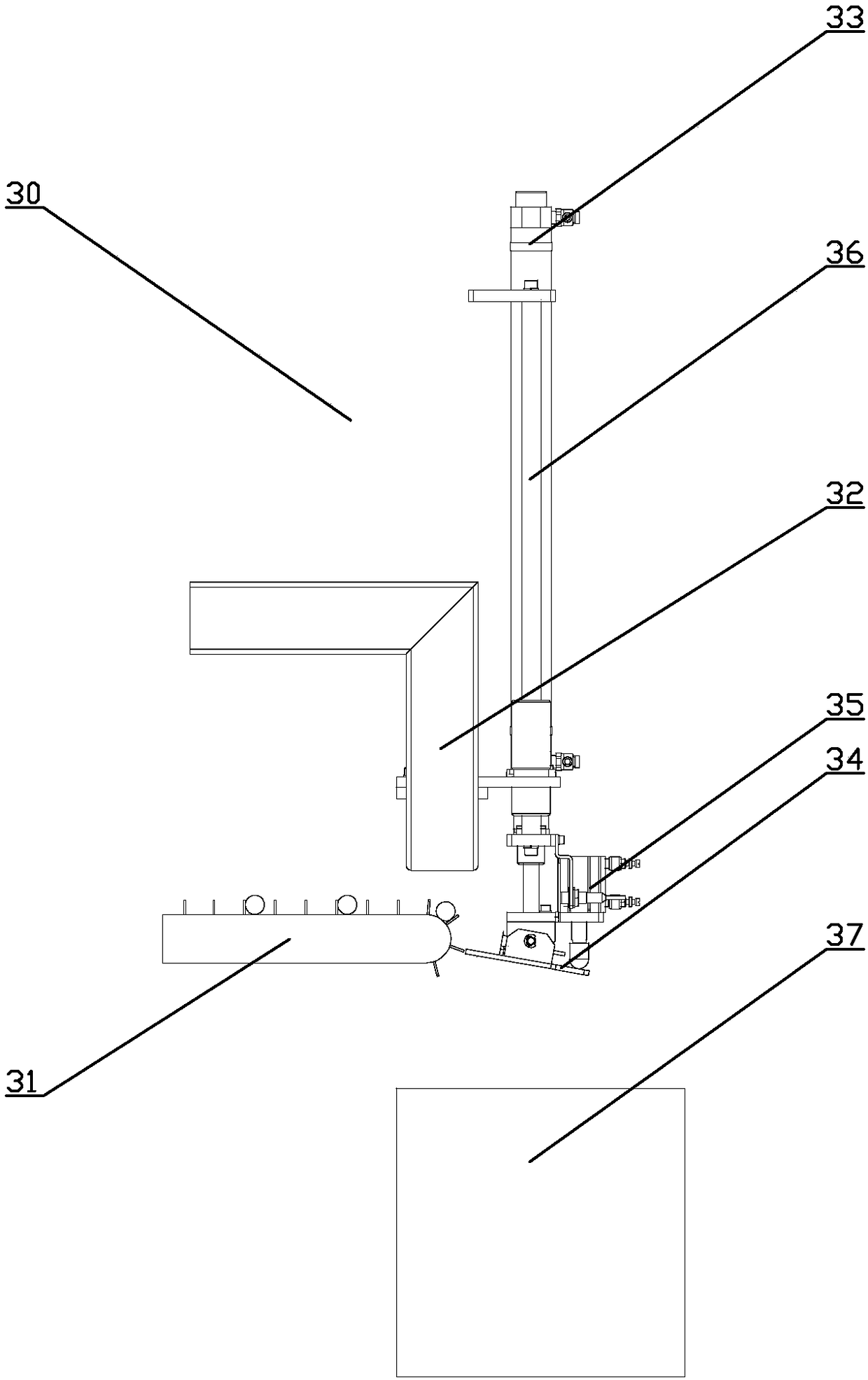

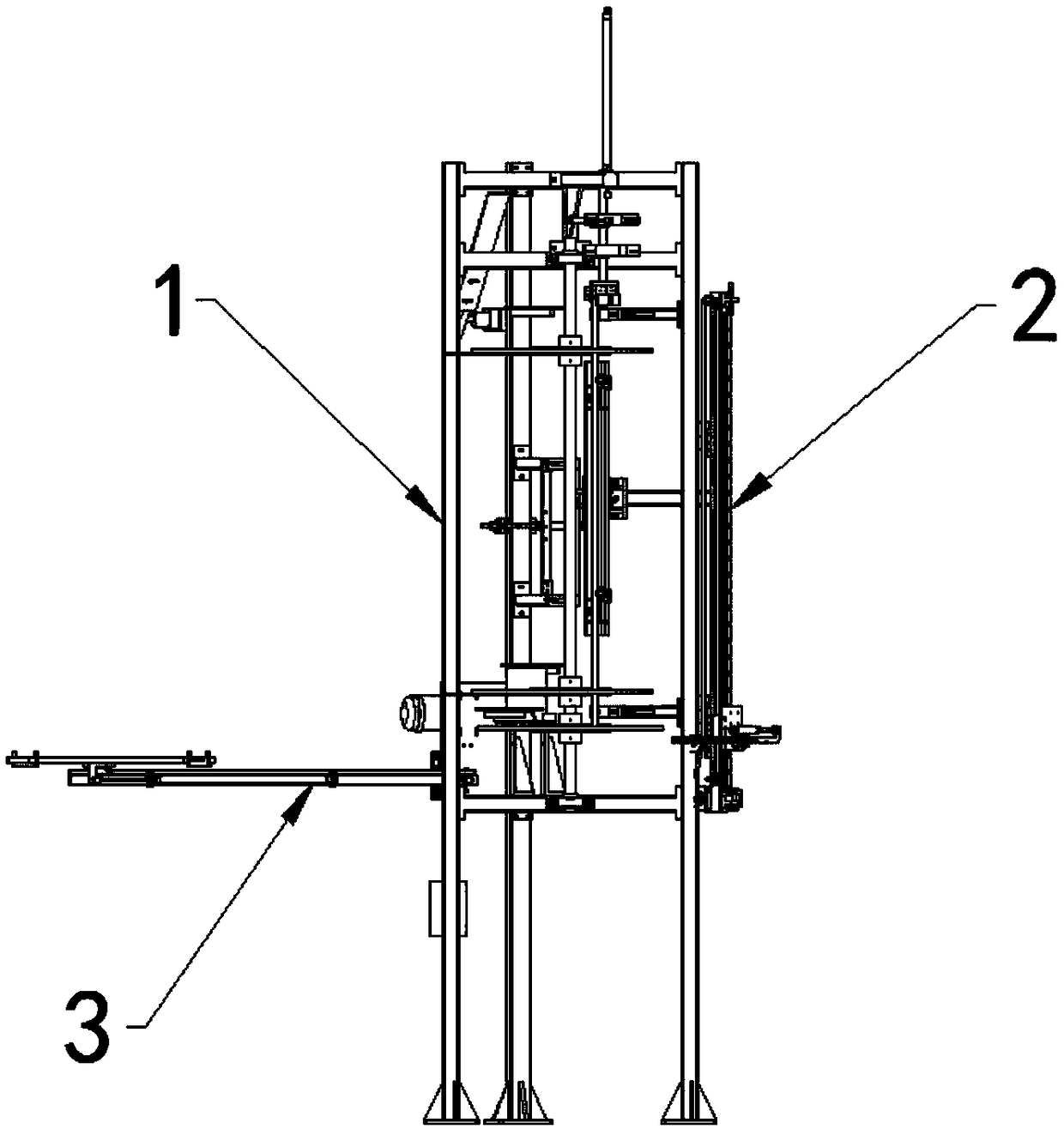

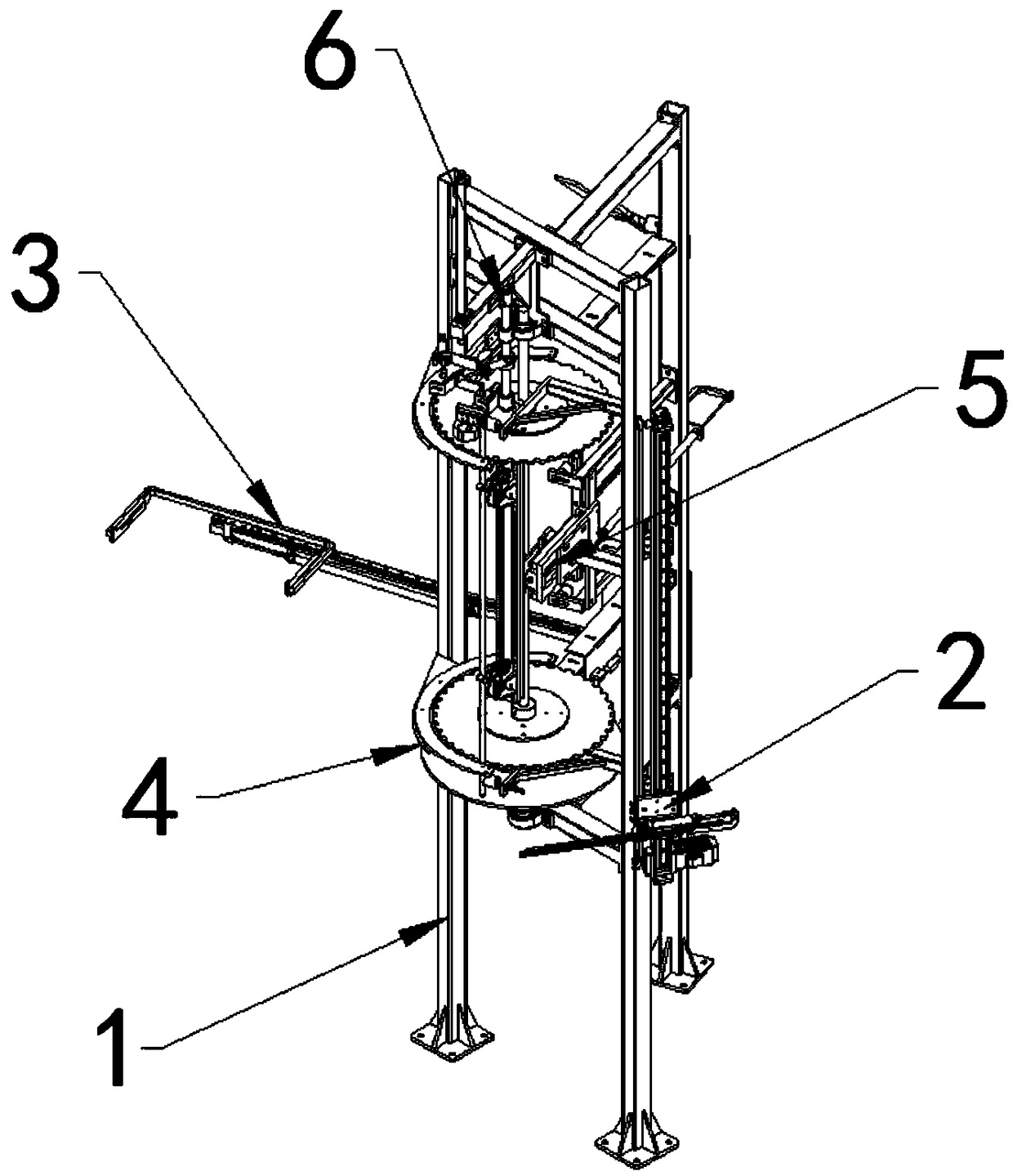

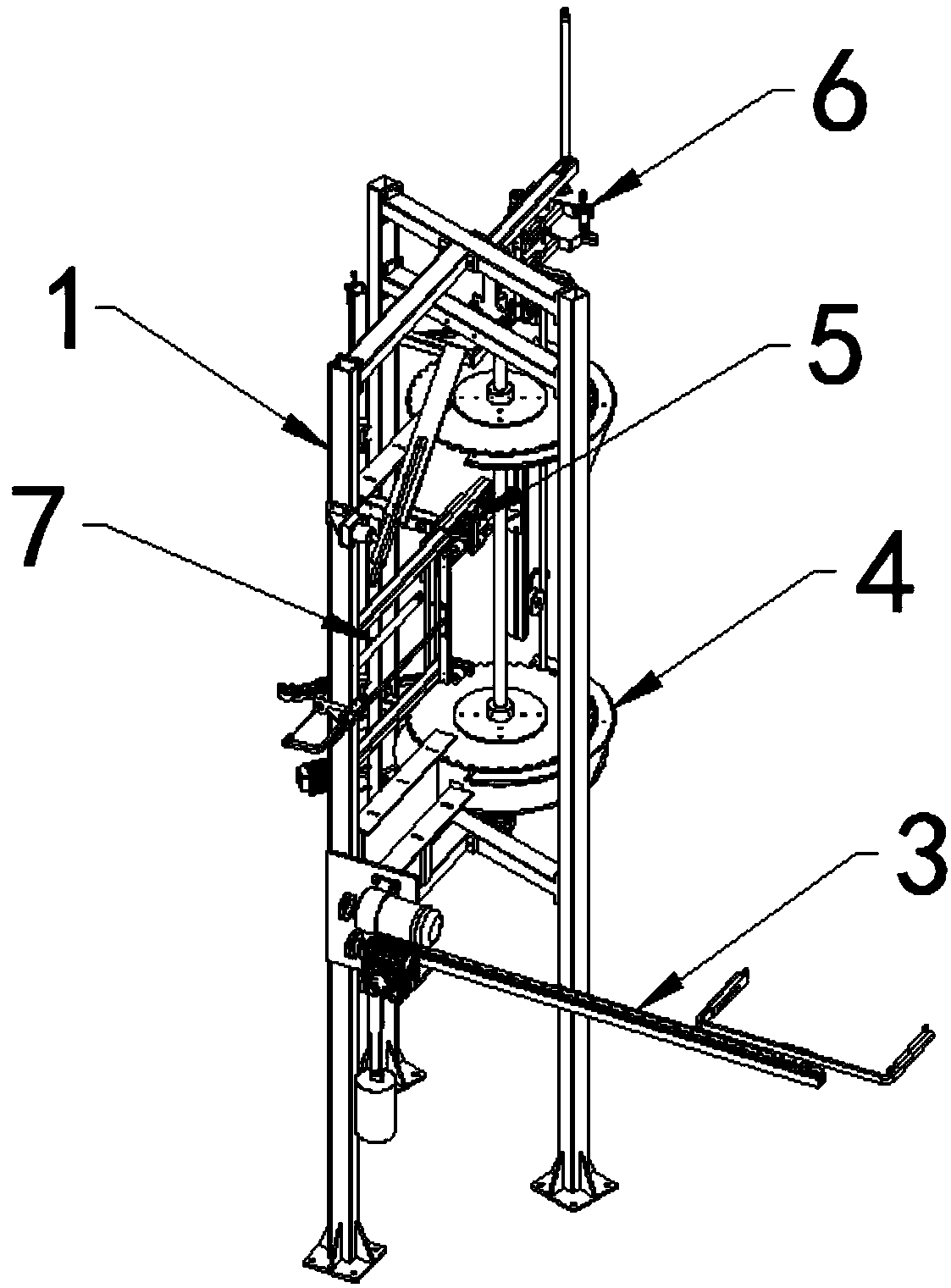

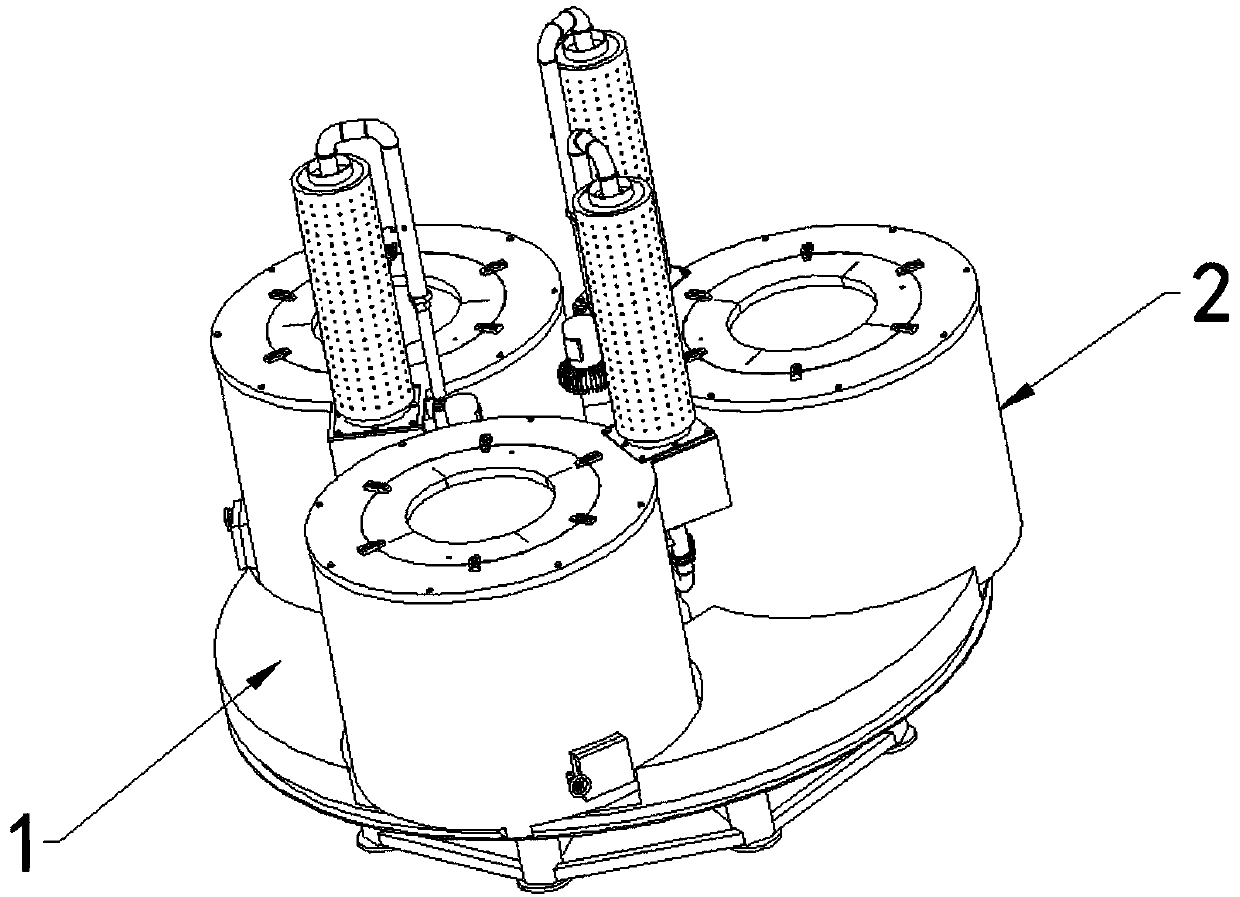

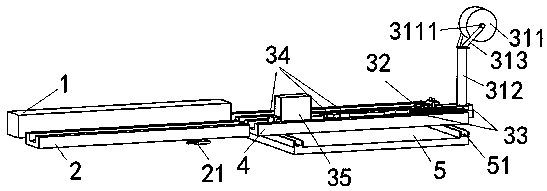

Ammunition static parameter automatic measuring device

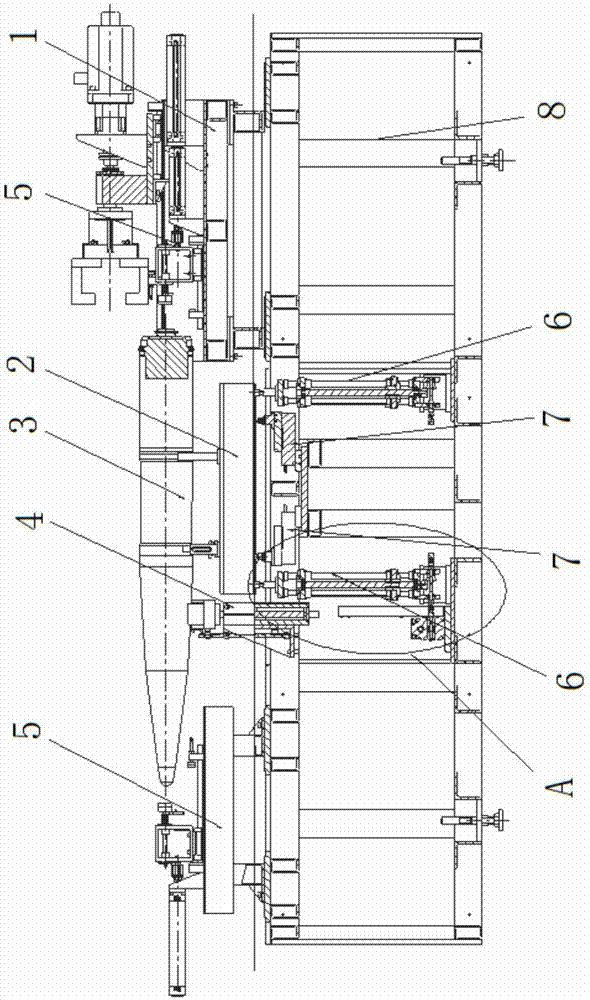

ActiveCN106855383ARealize integrated automatic measurementMeet the requirements of automated productionAmmunition testingLength measurementEngineering

The invention relates to the field of ammunition detection, and particularly relates to an ammunition static parameter automatic measuring device which is the integration of the measurement of mass, center of mass, centroidal deviation and the length of the ammunition, wherein the ammunition static parameter automatic measuring device comprises a rotary driving mechanism, a measuring bench, length measurement mechanisms, a lifting mechanism, a support frame body and a force measuring sensor, the two length measurement mechanisms are arranged at the front and rear ends of the upper table board of the support frame body respectively, the rotary driving mechanism is arranged above the length measurement mechanisms at the rear end of the support frame body, the middle of the upper table board of the support frame body is provided with the measuring bench, the position, below the measuring bench, of the support frame body is internally provided with the lifting mechanism, the force measuring sensor is arranged between the measuring bench and the upper table board of the support frame body, the measuring bench is driven to descend on the force measuring sensor through the lifting mechanism, when the measuring bench is driven to ascend to make the axis of a product to be measured is as high as that of the rotary driving mechanism, the product to be measured is clamed to rotate through the rotary driving mechanism. The ammunition static parameter automatic measuring device is the integration of multiple functions, can achieve automatic measurement of multiple parameters, and is high in measurement efficiency.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

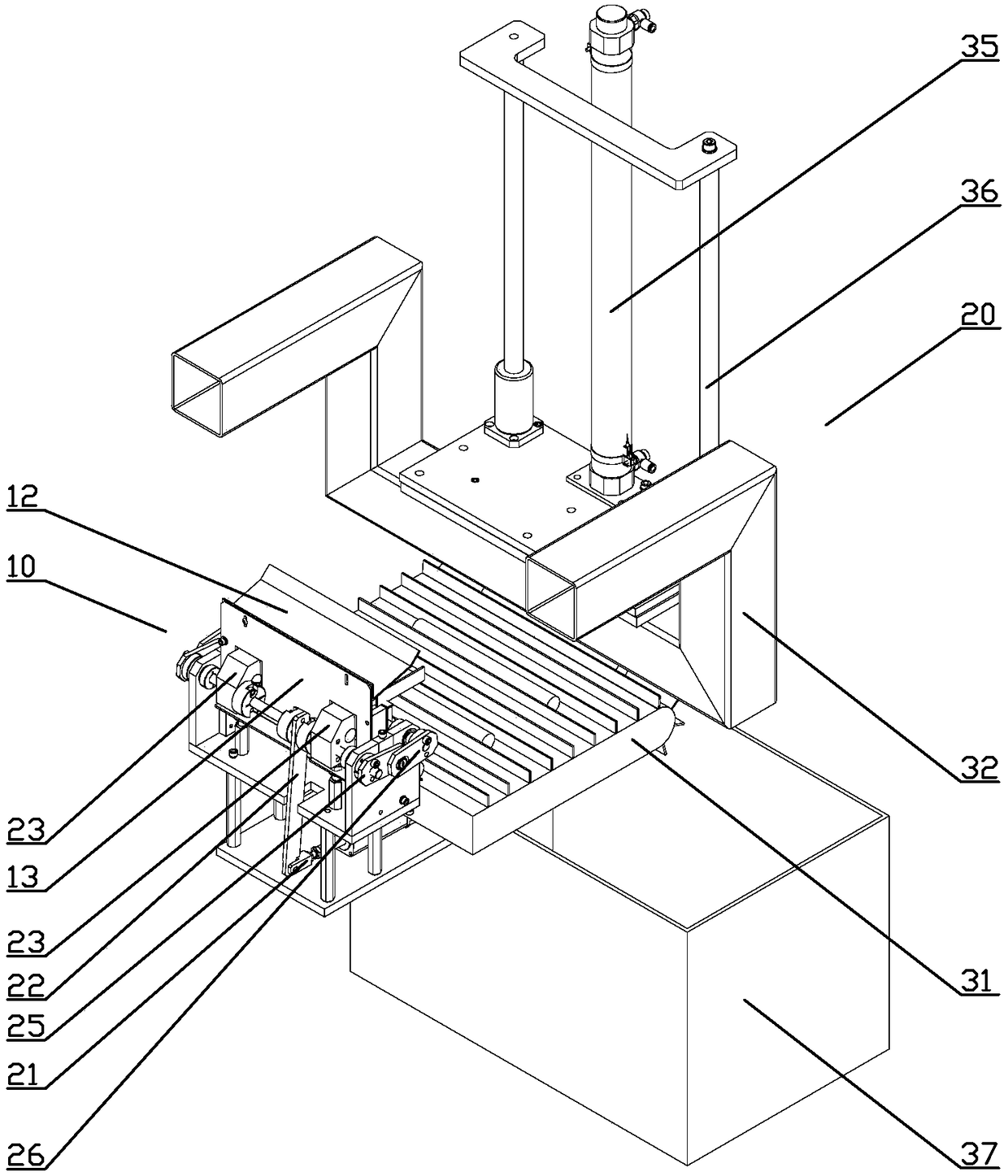

Automatic blank fetching equipment

InactiveCN103612908AHigh degree of automationIncrease productivityConveyorsStacking articlesMechanical equipmentEngineering

The invention belongs to the technical field of mechanical equipment, in particular to automatic blank fetching equipment. The automatic blank fetching equipment solves the technical problems that practicality is poor in the prior art. The automatic blank fetching equipment comprises a rack, a mechanical arm is arranged on the rack, a longitudinal translation driving mechanism capable of driving the mechanical arm to shift horizontally and repeatedly in the longitudinal direction of the rack is arranged between the rack and the mechanical arm, a disc sending lifting frame and a disc receiving lifting frame used for stacking blank discs are arranged on the two sides of the rack respectively, and blank discs stacked on the disc receiving lifting frame are located below the longitudinal translation track of the mechanical arm. A lifting driving device is arranged on the rack, wherein the lifting driving device is respectively connected to the disc sending lifting frame and the disc receiving lifting frame, and can drive the disc sending lifting frame and the disc receiving lifting frame to carry out synchronous reversed lifting motion on the two sides of the rack. A disc conveying device capable of enabling the top blank disc to be conveyed to the side, where the disc receiving lifting frame is located, of the rack from the side where the disc sending lifting frame is located, of the rack is further arranged on the rack. Compared with the prior art, the automatic blank fetching equipment has the advantage of being high in automation degree.

Owner:HANGZHOU DONGBO AUTOMATION SCI & TECH

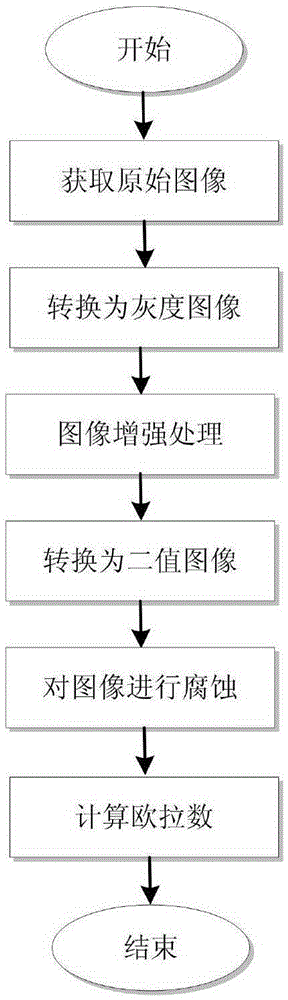

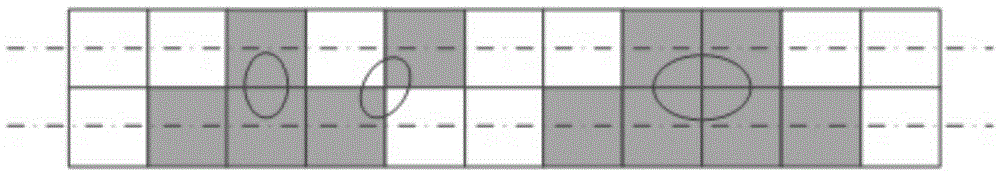

Method for counting number of reinforced steel bars based on computer vision

InactiveCN105303233AReduce labor intensityReduce error rateCharacter and pattern recognitionCounting objects in stackColor imageCounting Number

The invention relates to a method for counting the number of reinforced steel bars based on computer vision, which comprises the steps of firstly acquiring an original color image of the cross section of a measured reinforced steel bar bundle, and converting the original color image into a 256-color gray image; then carrying out enhancement processing on the gray image by using a filtering window, selecting an appropriate threshold, and converting the enhancement processed image into a binary image which only has two colors which are black and white; and finally carrying out etching on the binary image by using an etching method, and calculating an Euler number of the etched binary image, wherein the value is the counted number of the reinforced steel bars. According to the invention, the whole process of counting for the reinforced steel bars is realized automatically, and the number of the reinforced steel bars can be counted in a short time, thereby reducing the labor intensity of workers and the error rate, improving the production efficiency, being high in counting accuracy and speed, and being capable of meeting requirements of automatic production.

Owner:SHAANXI UNIV OF SCI & TECH

Automatic glass tube feeding and insertion production line for glass tube production

InactiveCN108726857AReduce labor costsIncrease productivityGlass reforming apparatusProduction lineDrive shaft

The invention discloses an automatic glass tube feeding and insertion production line for glass tube production. The production line comprises a tube feeding machine, wherein the tube feeding machinecomprises a feeding rack and a caterpillar track feeding device and a glass tube conveying device which are respectively mounted on the feeding rack; the caterpillar track feeding device comprises a caterpillar track and a plurality of partition plates which are arranged on the surface of the caterpillar track; a driving shaft and a driven shaft are respectively arranged inside the caterpillar track; a rotating motor for driving the driving shaft to rotate is mounted on the feeding rack. Due to adoption of the caterpillar track feeding device, glass tubes are piled on the feeding rack, the rotating motor is controlled to work, then the caterpillar track can be indirectly driven to rotate by the rotating motor, the glass tubes can be clamped into a stripy groove and are risen along with thecaterpillar track while the caterpillar track is rotated, later the glass tubes are fed into a first glass tube support rack and are finally inserted into object clamps of a next procedure through atube insertion machine, the whole process is automatically completed by the machines, a great deal of labor cost can be reduced, and high production efficiency can be achieved.

Owner:黎泽新

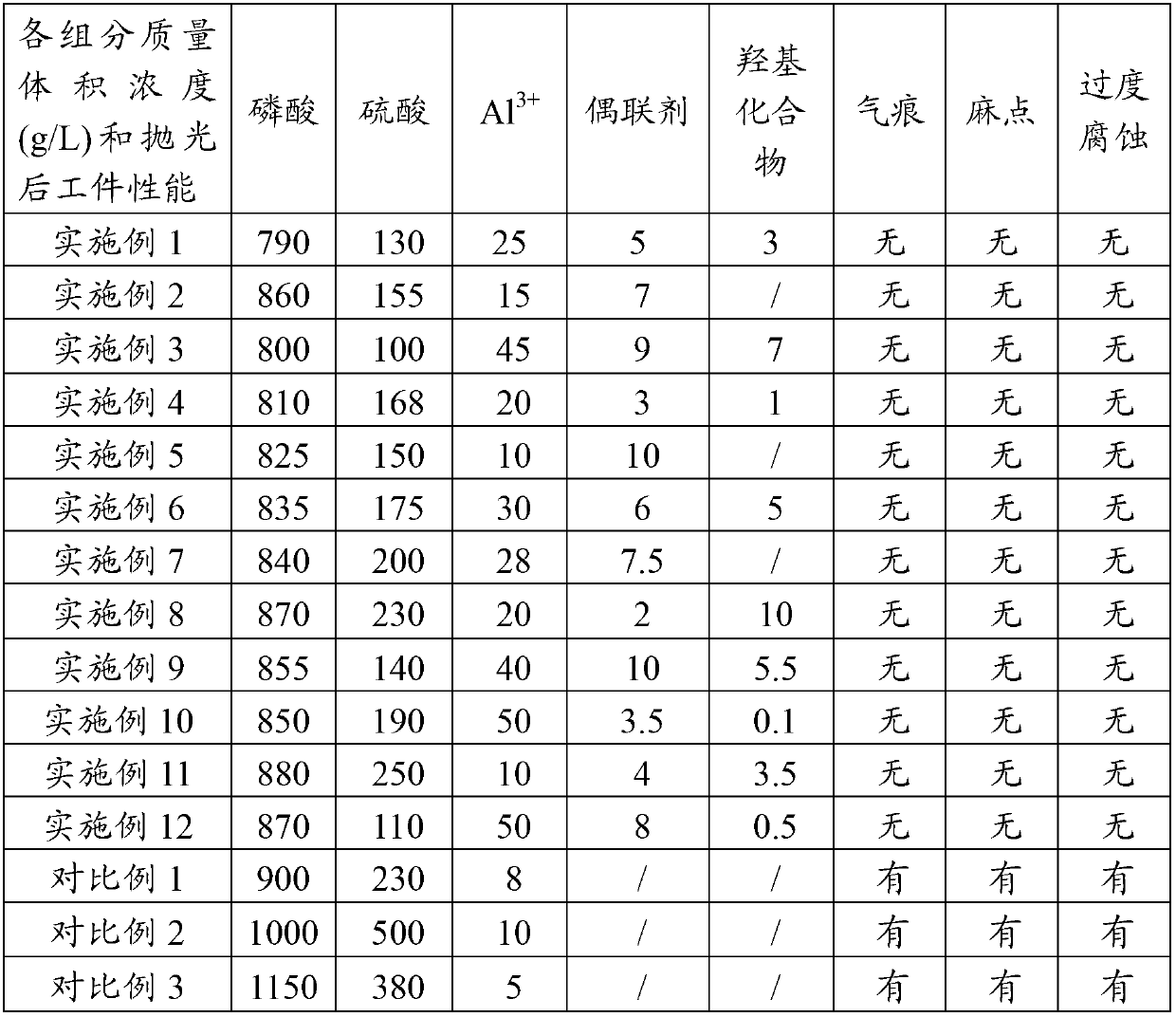

Chemical polishing agent

The invention discloses an aluminum alloy chemical polishing agent applicable to automatic production. The chemical polishing agent comprises aqueous solutions of the following substances: according to mass-volume concentration, 790g / L to 880g / L of phosphoric acids, 100g / L to 250g / L of sulfuric acids, 10g / L to 50g / L of aluminum ions and 2g / L to 10g / L of coupling agents. According to the chemical polishing agent, the proportion of the phosphoric acids and the sulfuric acids is adjusted, and aluminum ions are further added, so that the corrosion of the polishing agent is reduced. The viscosity of the polishing agent is added by the adding of the coupling agents, so that the flow speed of gas released in the polishing process is changed, and the gas cannot leave gas marks on workpieces after the polishing; besides, as the coupling agents can be attached onto the workpiece surface, a layer of protection film is formed between highly corrosive acids and alloy surfaces, so that excessive corrosion caused by the continuous reaction of workpieces after the workpieces leave polishing grooves (during the slow transfer of the automatic production) is avoided, and further, the production stability is guaranteed, and requirements of automatic production is met.

Owner:广州波耳化工科技有限公司

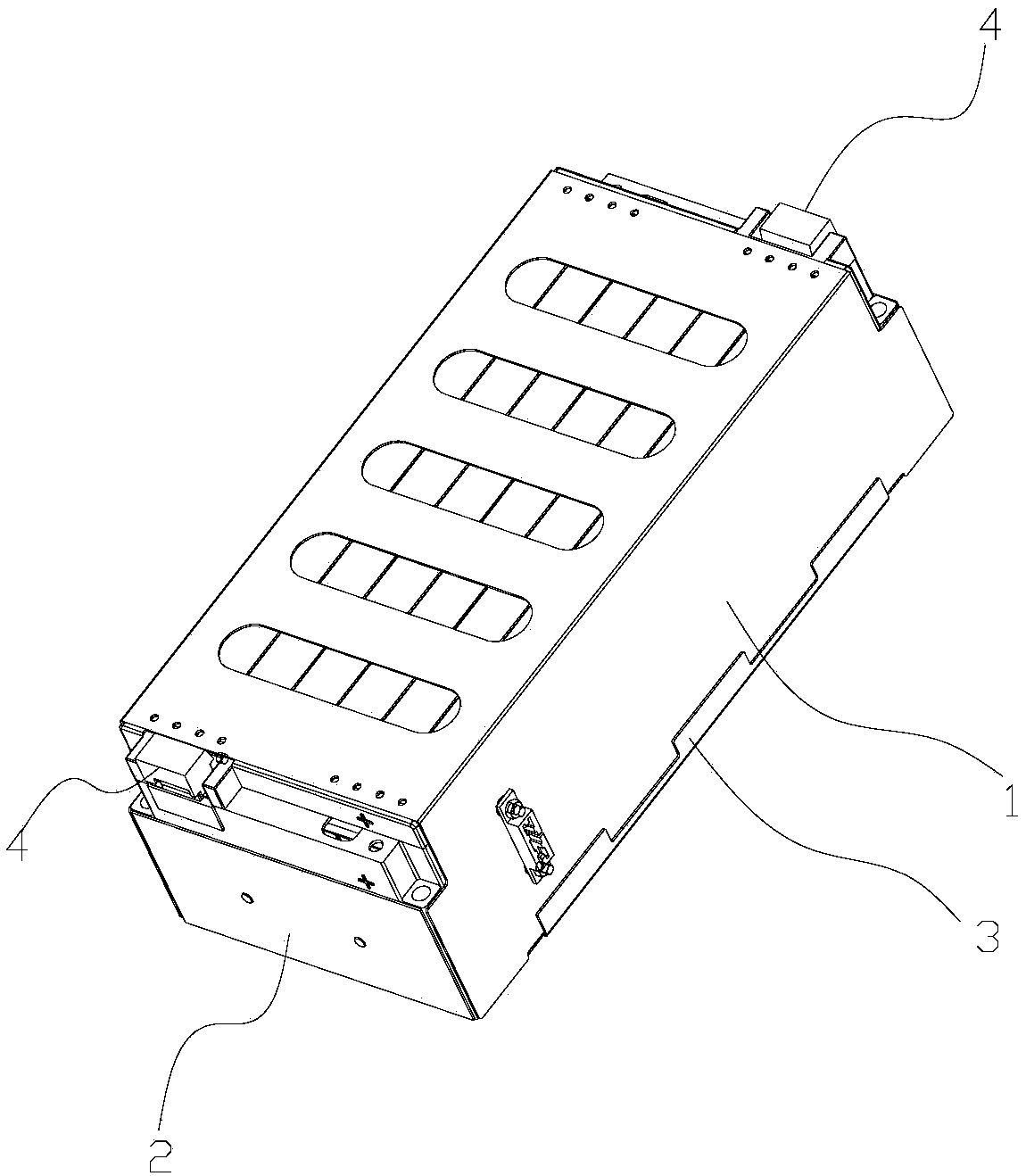

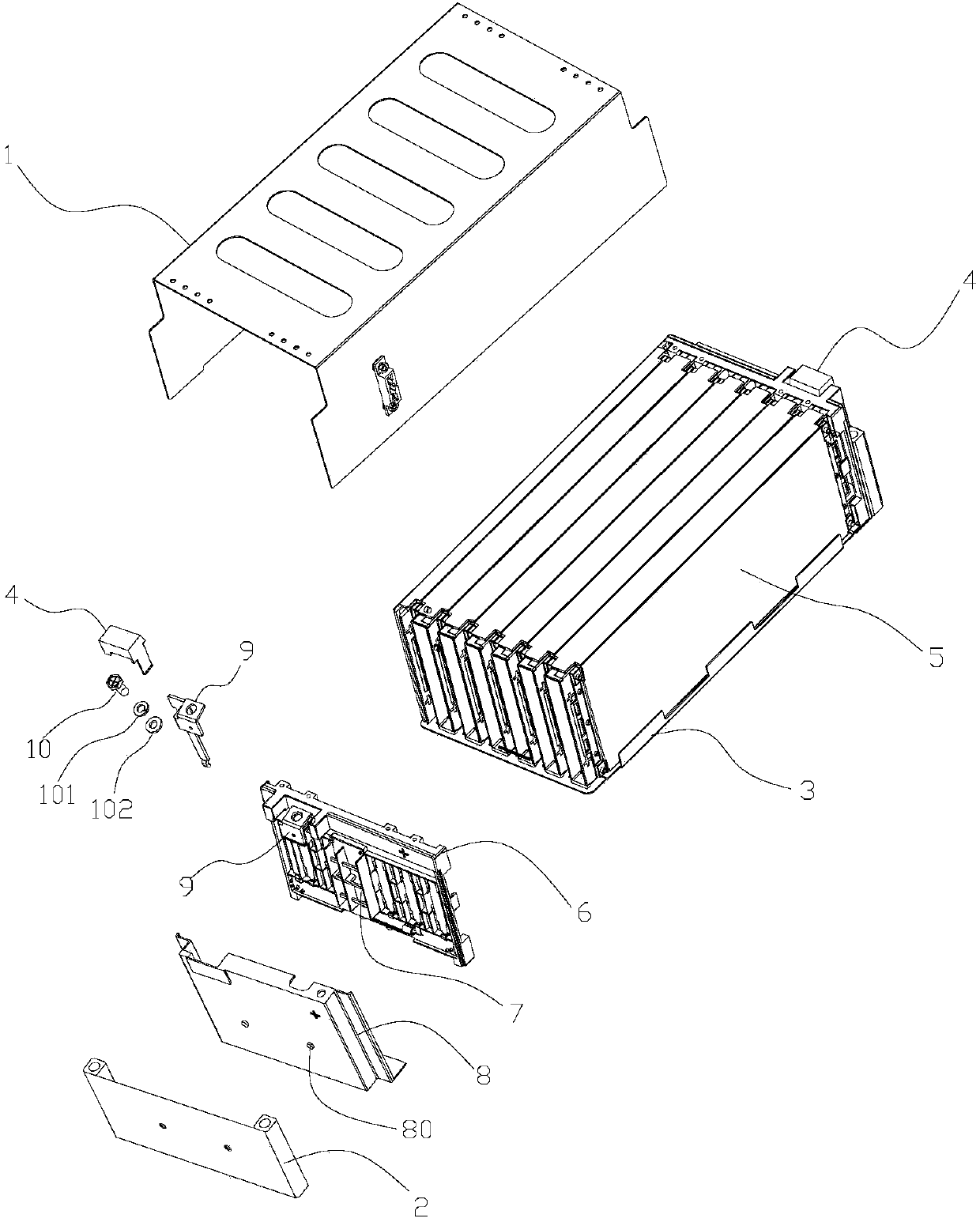

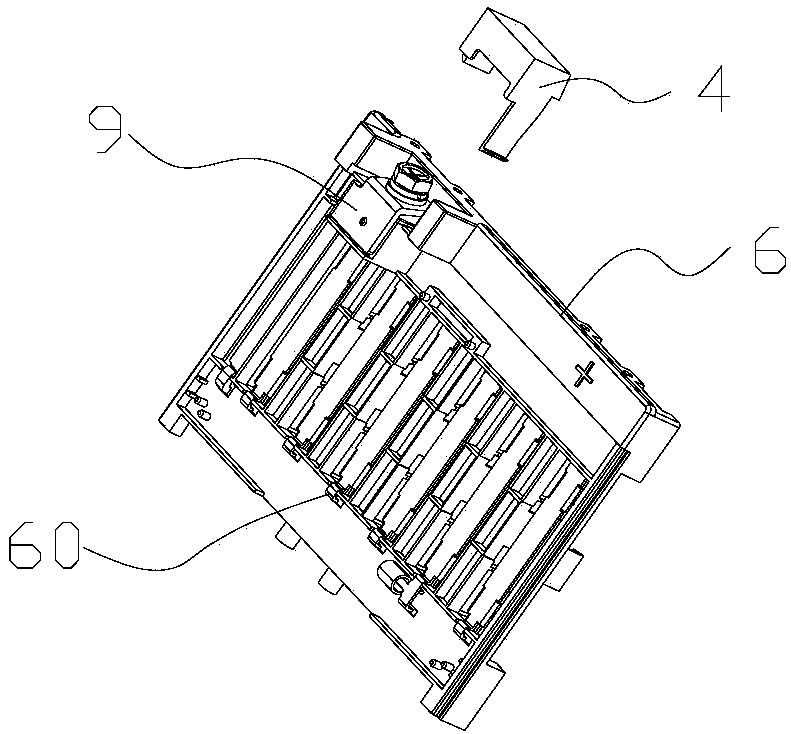

Novel power battery module structure

ActiveCN107946506AIncrease the proportionImprove versatilityCurrent conducting connectionsBatteriesPower batteryElectrical battery

The invention provides a novel power battery module structure. The novel power battery module structure comprises an outer cover plate, end plates, a bottom plate and a cell-BLOCK framework; the outercover plate comprises a top plate and side plates; the end plates are arranged at the two ends of the outer cover plate, and the end plates are used as fixed parts of the module; the outer cover plate and the end plates cover the bottom plate; the cell-BLOCK framework is arranged on the bottom plate and positioned in a framework which is formed by the outer cover plate and the end plates in a surrounding manner; the cell-BLOCK framework comprises a plurality of built-in single cells arranged side by side and a BLOCK framework; end copper plate assemblies are arranged at the two ends of the single cells; external ends are arranged on the end copper plate assemblies; the external ends are arranged at the two ends of the single cells to be used as end connectors of positive electrodes and negative electrodes; inner protection plates are arranged between the end copper plate assemblies and the end plates; and protection caps are arranged outside wiring bases on the upper parts of the external ends. By virtue of the novel power battery module structure, the cell duty ratio is improved, the module cost is lowered, and the module university is improved; and meanwhile, the module can be assembled simply, the module weight is lowered, and automatic production requirement can be satisfied.

Owner:TIANJIN ENERGIES

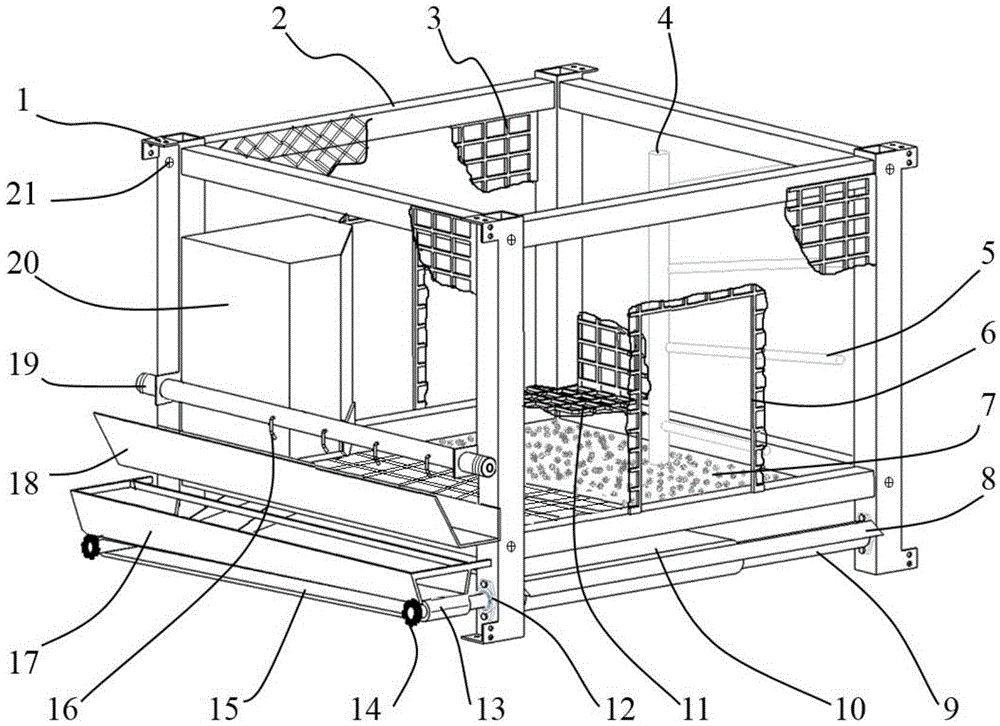

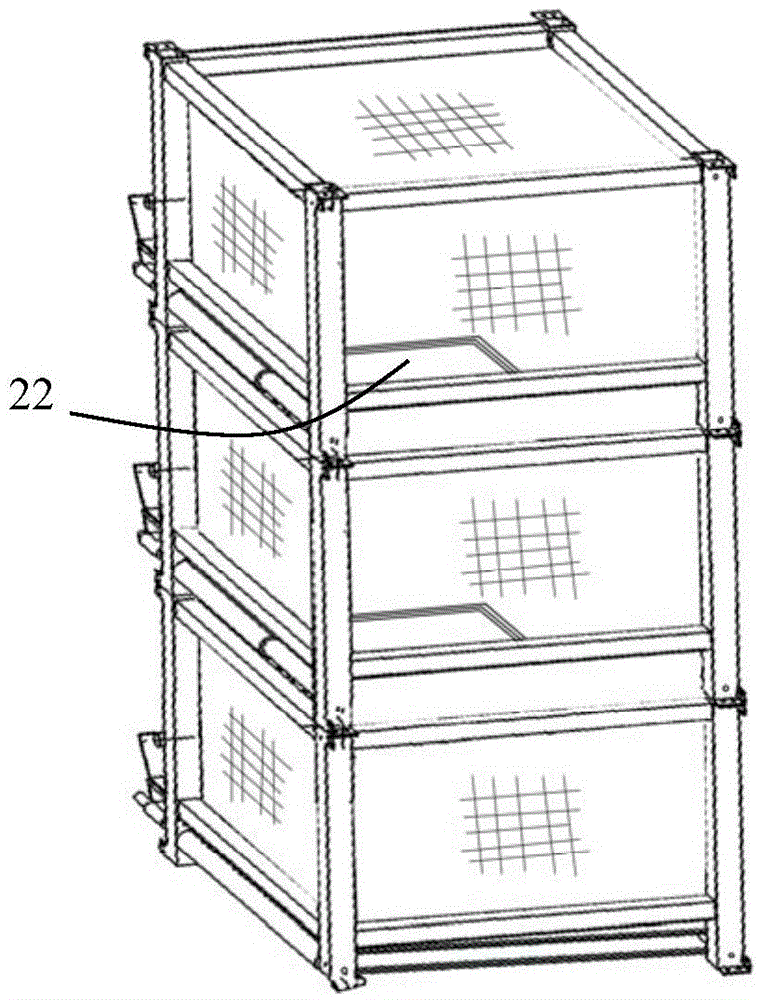

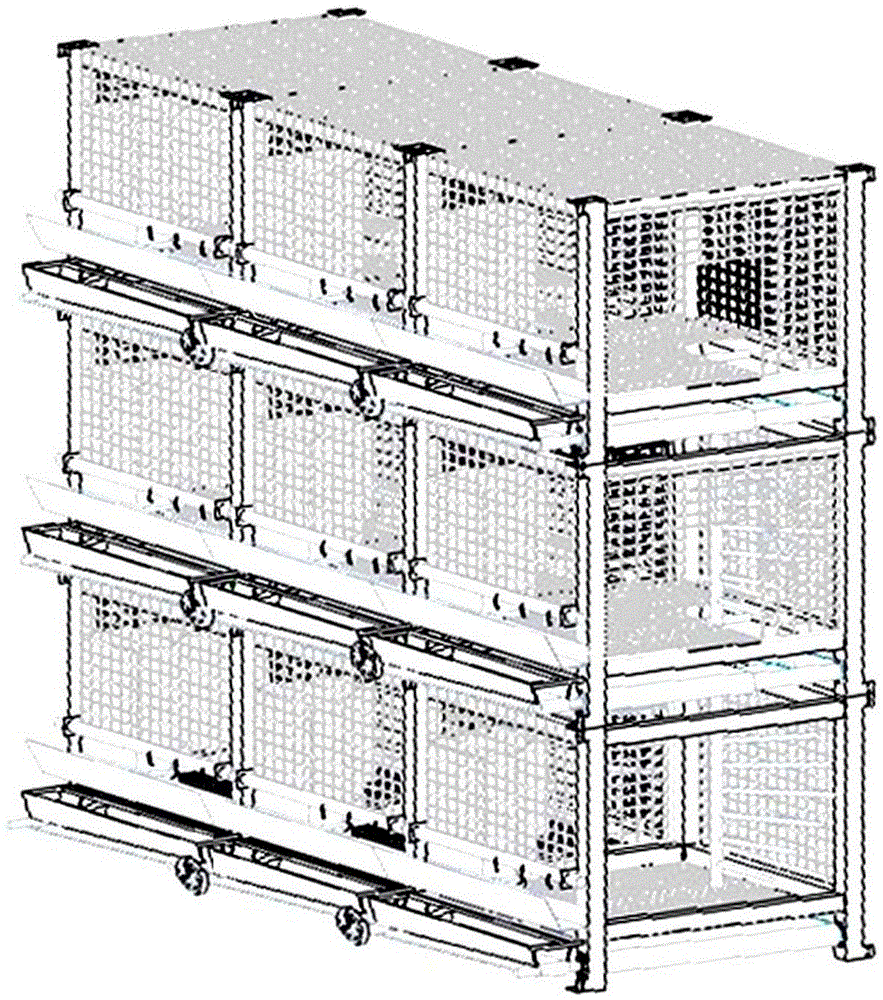

Unitized combined and assembled type egg welfare breeding cage

InactiveCN105638508AHabitat function is goodEfficient use of interior spaceBird housingsAnimal scienceWater drinking

The invention discloses a unitized combined and assembled type egg welfare breeding cage, and belongs to the technical field of livestock machines. The cage comprises supporting legs, a pipe frame, a surface net, perch frame columns, perch bars, a movable door, a manual meadow, a manure scraper, a roller shaft, a manure removal belt, a frame layer, a rolling piece, an egg rolling piece, synchronous teeth, an egg collecting belt, a nipple water drinking device, an egg baffle, a trough, a water drinking pipe, an egg laying box body, a connection pin, an interlayer door and an egg conveying channel. The cage can provide functions of egg collecting, conveying, eating, perching, frame connecting and the like. The cage is complete in structural function, can meet welfare habit behaviors of laying hens such as grabbing for rest, scratching and laying in the cage, can also meet the production requirements for automatic manure removing, egg collecting and the like, and greatly improves the welfare breeding level of laying hens; due to the modularized producing, manufacturing and assembling mode, multiple cages can be connected and assembled, the device manufacturing and investment cost is reduced, the space occupation of a single hen is further increased, and the cage conforms to the development tendency of industrial welfare breeding.

Owner:NORTHWEST A & F UNIV

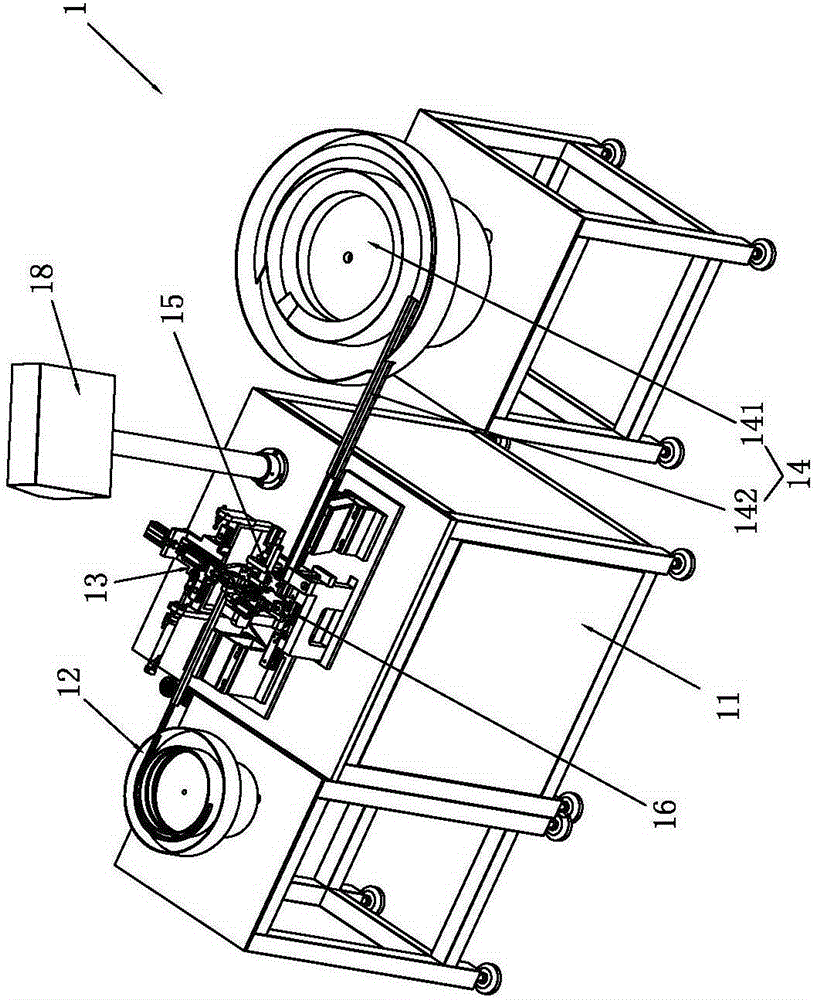

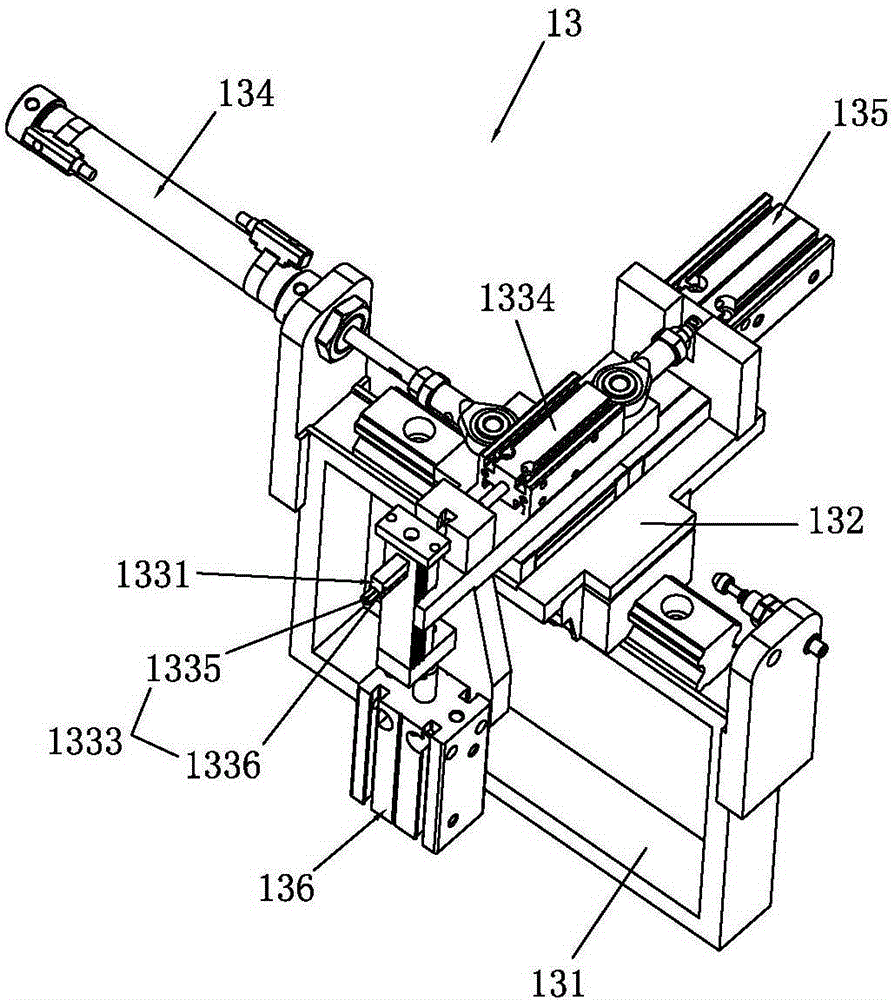

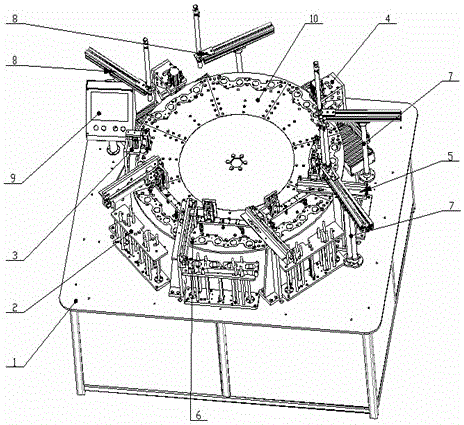

Full-automatic assembly machine for hook buckles

ActiveCN106736499ARealize automated assemblyIncrease productivityAssembly machinesEngineeringMachining

The invention relates to automatic assembly equipment, in particular to a full-automatic assembly machine for hook buckles. The full-automatic assembly machine comprises a control device, a rotatable workbench, a hook body feeding mechanism, a trigger feeding mechanism, a rivet feeding mechanism and a riveting mechanism, wherein the hook body feeding mechanism, the trigger feeding mechanism, the rivet feeding mechanism and the riveting mechanism are sequentially arranged outside the workbench according to the sequence of workpiece machining. The workbench, the hook body feeding mechanism, the trigger feeding mechanism, the rivet feeding mechanism and the riveting mechanism are in electric connection with the control device, and a trigger assembly mechanism is connected to the feeding end of the trigger feeding mechanism. According to the full-automatic assembly machine for the hook buckles, automatic assembly of hook bodies and triggers can be achieved, working efficiency is high, labor cost is low, accuracy of products is high, and the requirement for automatic production is met.

Owner:东莞市迈悦五金塑胶制品有限公司

Concrete block stacking machine

InactiveCN106395397AReduce labor intensityReduce manufacturing costStacking articlesDe-stacking articlesMachine partsBrick

The invention discloses a concrete block stacking machine which comprises a feeding conveying belt, a stacking conveying belt, a stacking machine part and a pallet conveyer; the stacking conveying belt is arranged on one side of the feeding conveying belt, and is parallel to the feeding conveying belt; the stacking machine part comprises a supporting rack, guide rails, a lifting device, a transverse clamping rack, a longitudinal clamping rack and a platform; the supporting rack is in a portal structure, and is arranged above the feeding conveying belt and the stacking conveying belt; and the pallet conveyer comprises a rack, a left clamping plate, a right clamping plate, a synchronizing device and a driving liquid press cylinder. With the adoption of the technical scheme and measures, the conventional block stacking machine is improved; the concrete block stacking machine meets the requirements of automatic production fully; no labor is required to unload blocks from a kiln car; no manual stacking or manual loading is required; the production efficiency is improved; and the labor intensity of workers and the production cost are reduced substantially.

Owner:吉林久盛生态环境科技有限公司 +1

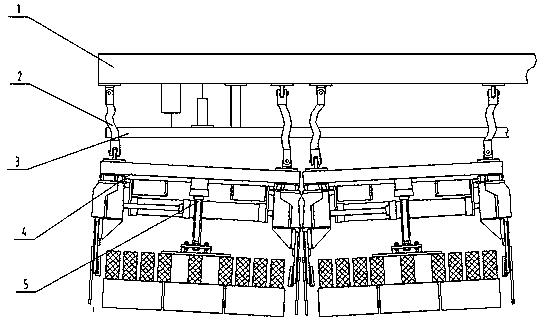

High-power laser chip test aging clamp

PendingCN111352024AEasy clampingIncrease production capacityElectronic circuit testingMeasurement instrument housingTemperature controlEngineering

The invention relates to the technical field of testing and aging equipment, and especially relates to a high-power laser chip test aging clamp. A positioning sheet is fixed on a heat dissipation base, a laser chip is placed on the positioning sheet, a temperature control circuit board is also arranged on the heat dissipation base, a power-up circuit board is arranged above the temperature controlcircuit board, the power-up circuit board is electrically connected with the laser chip, the power-up circuit board is connected with a power supply in test aging equipment, the positioning sheet isprovided with a positioning groove, the laser chip is positioned and placed in the positioning groove, one end of the power-up circuit board is provided with a power-up electrode, the power-up electrode is electrically connected with the laser chip, and the temperature control circuit board is provided with a thermistor. Compared with like clamps in the prior art, the high-power laser chip test aging clamp can test aging of laser chips of different specifications only by adjusting the positioning groove of the positioning sheet and the power-up electrode of the power-up circuit board, so the universality is enhanced, clamping and production circulation of the laser chips are facilitated, and the production efficiency can be improved.

Owner:镭神技术(深圳)有限公司

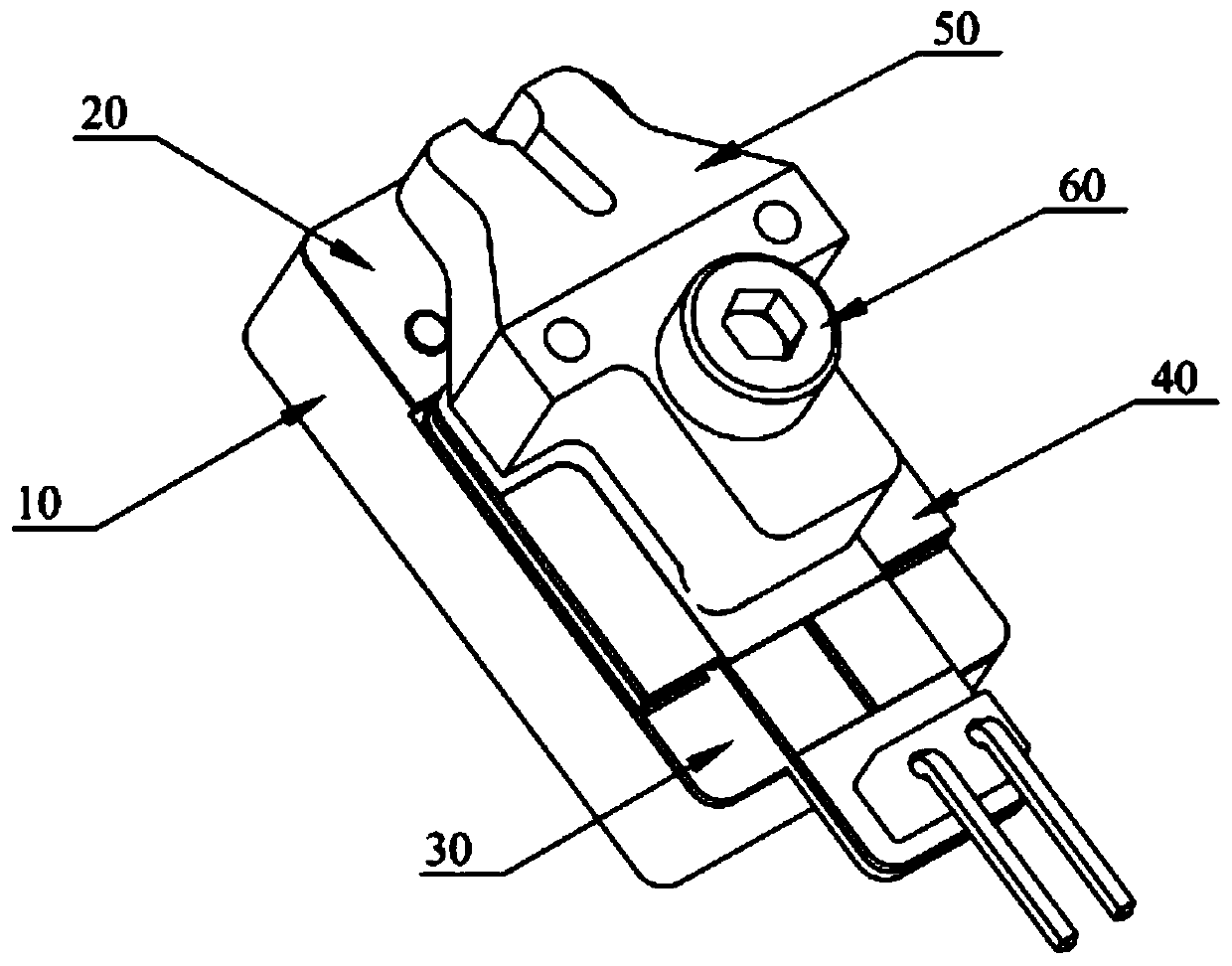

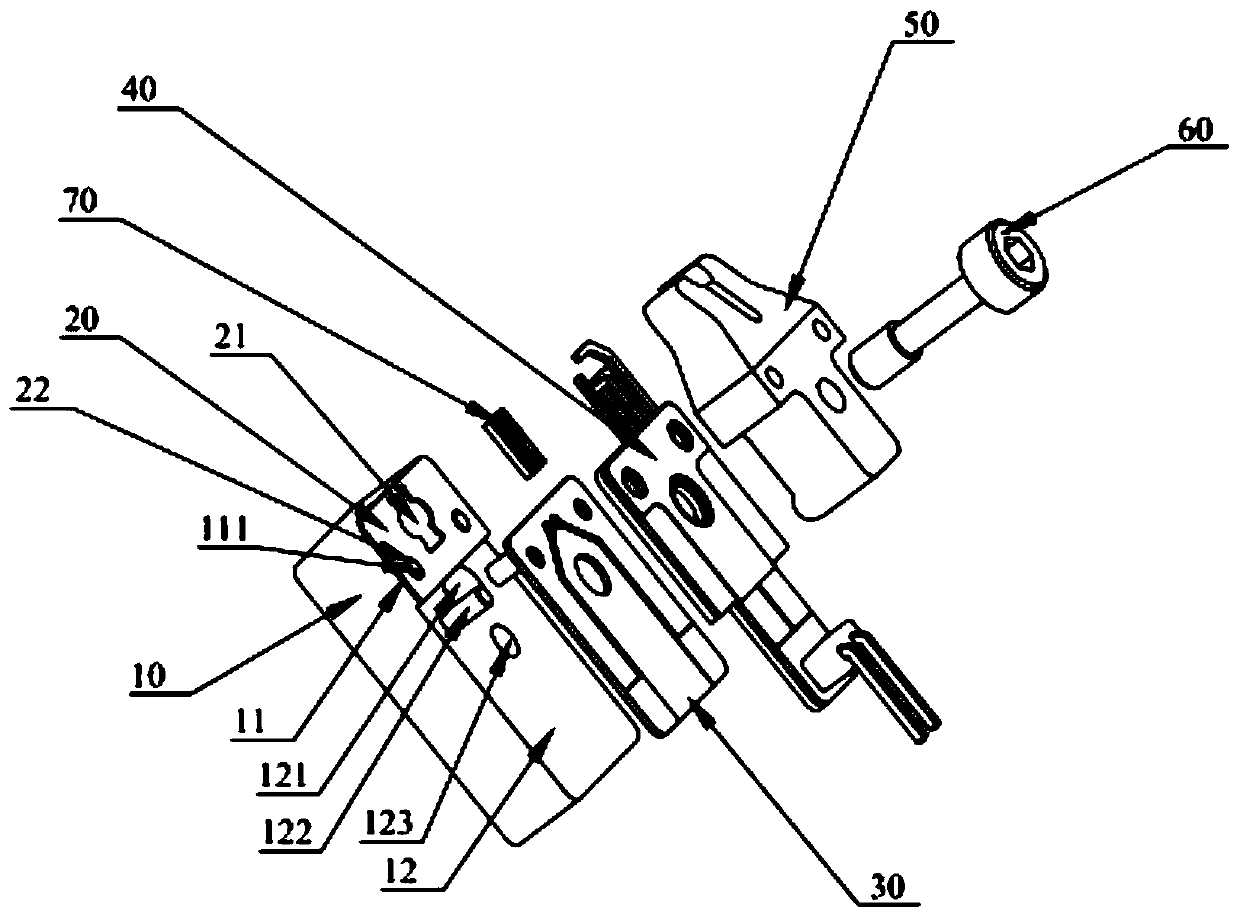

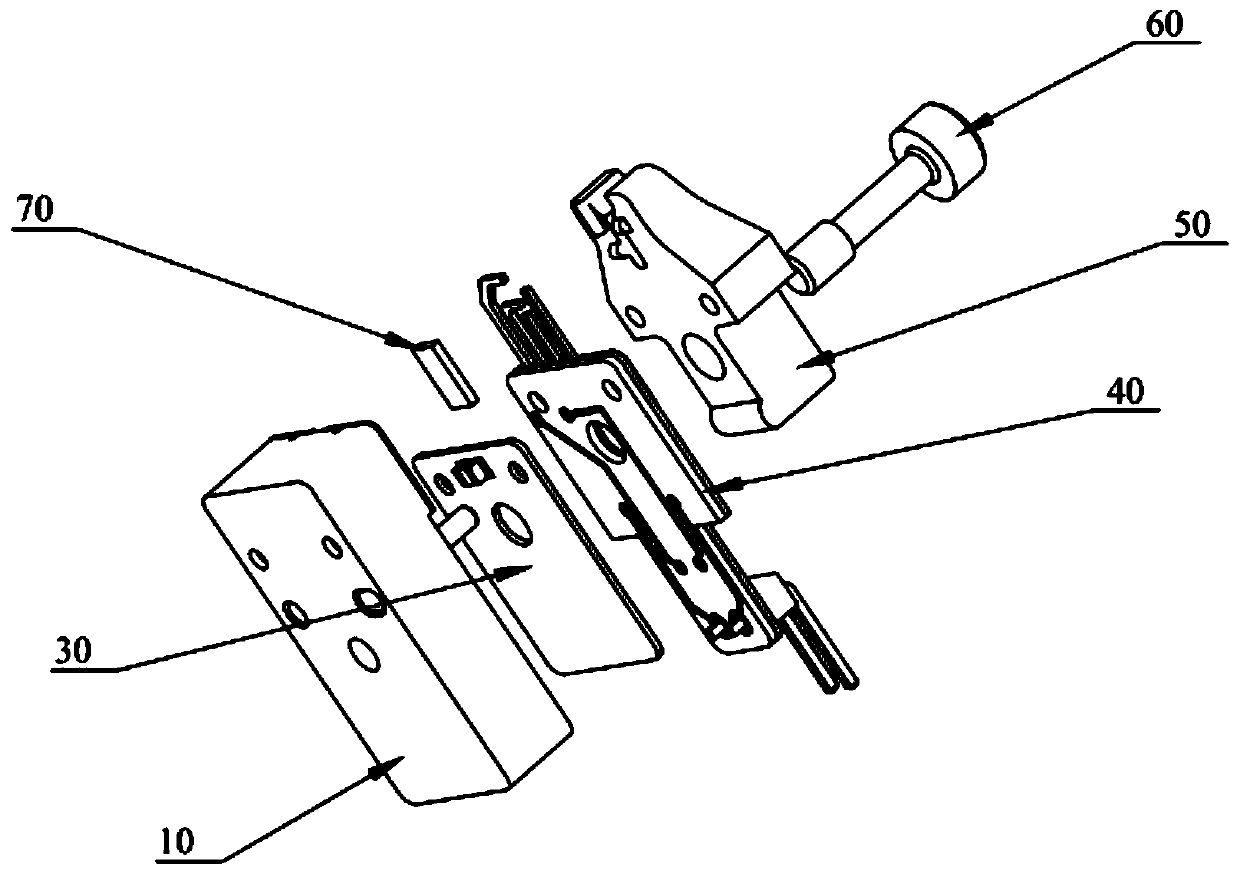

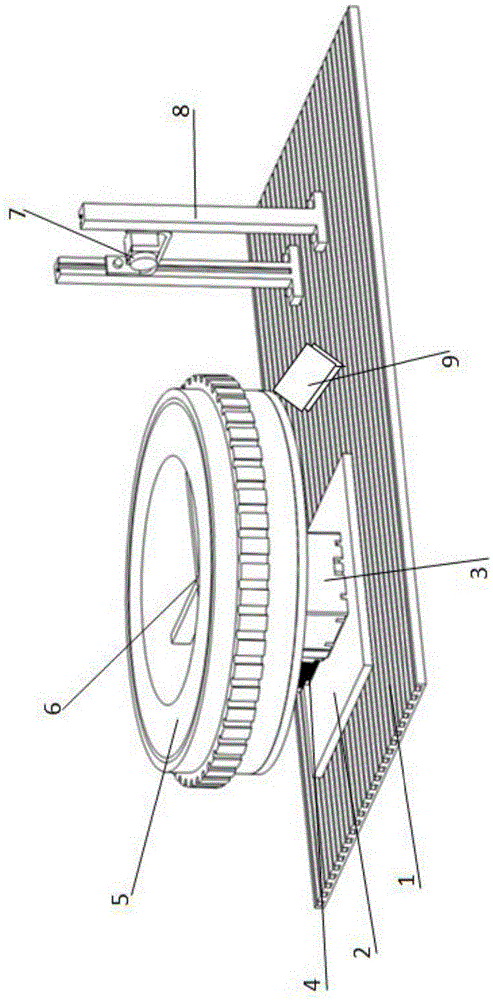

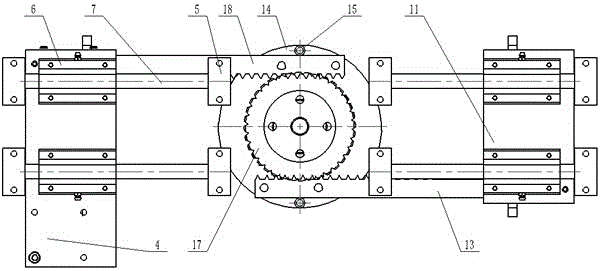

Inner hole clamping device

PendingCN107650138ARealize automatic alignmentRealize automatic centeringGripping headsConveyor partsEngineeringSmall hole

The invention provides an inner hole clamping device. The inner hole clamping device can solve the problem that a traditional spring sleeve cannot conduct reliable clamping or picking on small-inner-hole, large-dead-load and long-inner-hole workpieces, and accordingly the industrial machine automatic production requirement can be met. The inner hole clamping device comprises a core bar and a drivemechanism, the core bar is provided with an axial center through hole, the axial center through hole is internally provided with a pull rod in a penetrating manner, the pull rod can move in the axialdirection, the front end of the pull rod is connected with a pulling block, and the rear end of the pull rod is connected with the drive mechanism. Three sliding grooves which horizontally extend inthe axial direction and are parallel are evenly distributed in the peripheral face of the front end of the core bar in the circumferential direction. The groove bottom faces of the sliding grooves arewedge-shaped groove faces with the radial groove depths gradually increased from back to front. Each of the three sliding grooves internally contains a sliding claw, each sliding claw is provided with a wedge-shaped inclined face which is in sliding fit with the corresponding wedge-shaped groove, and the front end of each sliding claw is fixedly connected with the pulling block.

Owner:昆山巨林科教实业有限公司

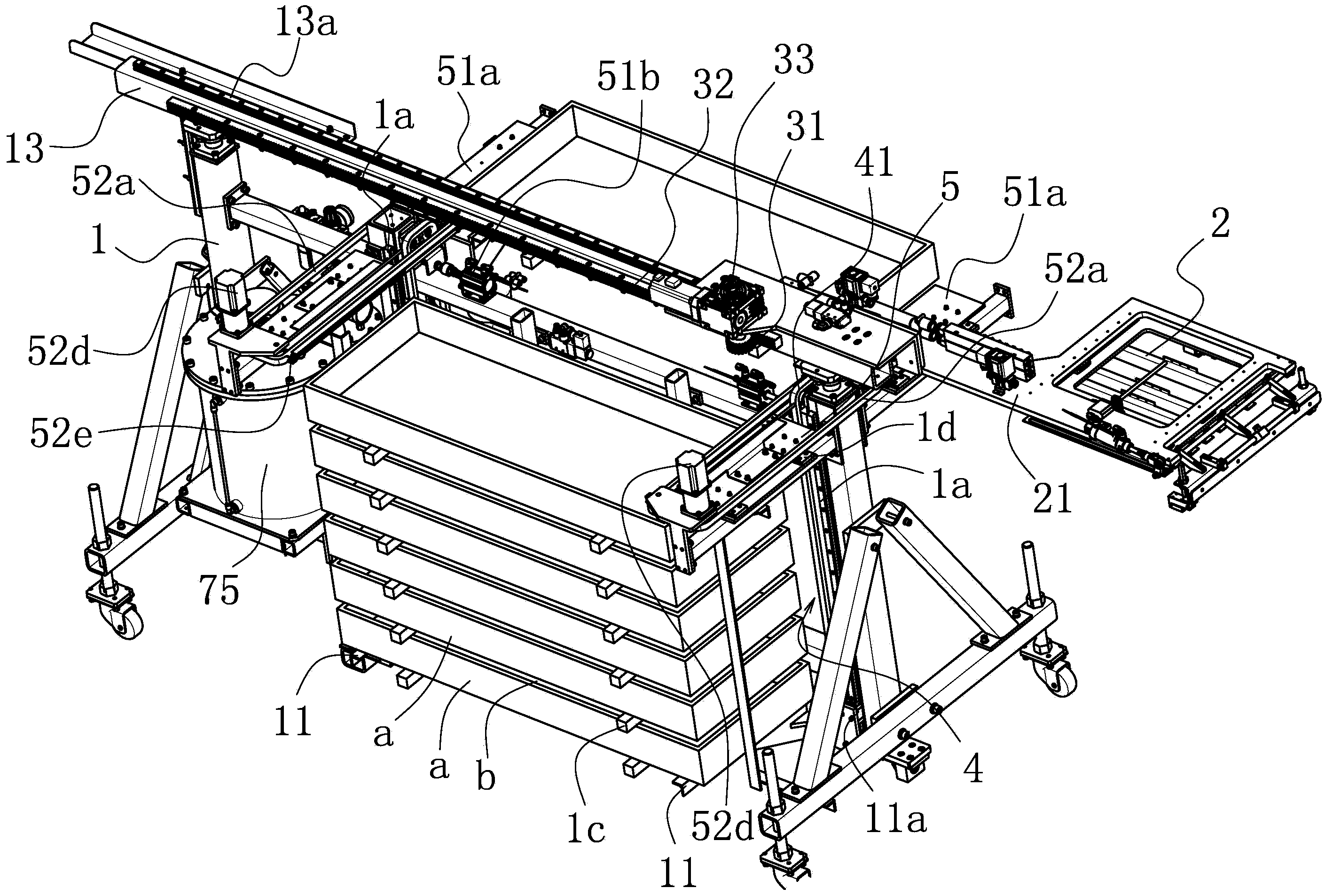

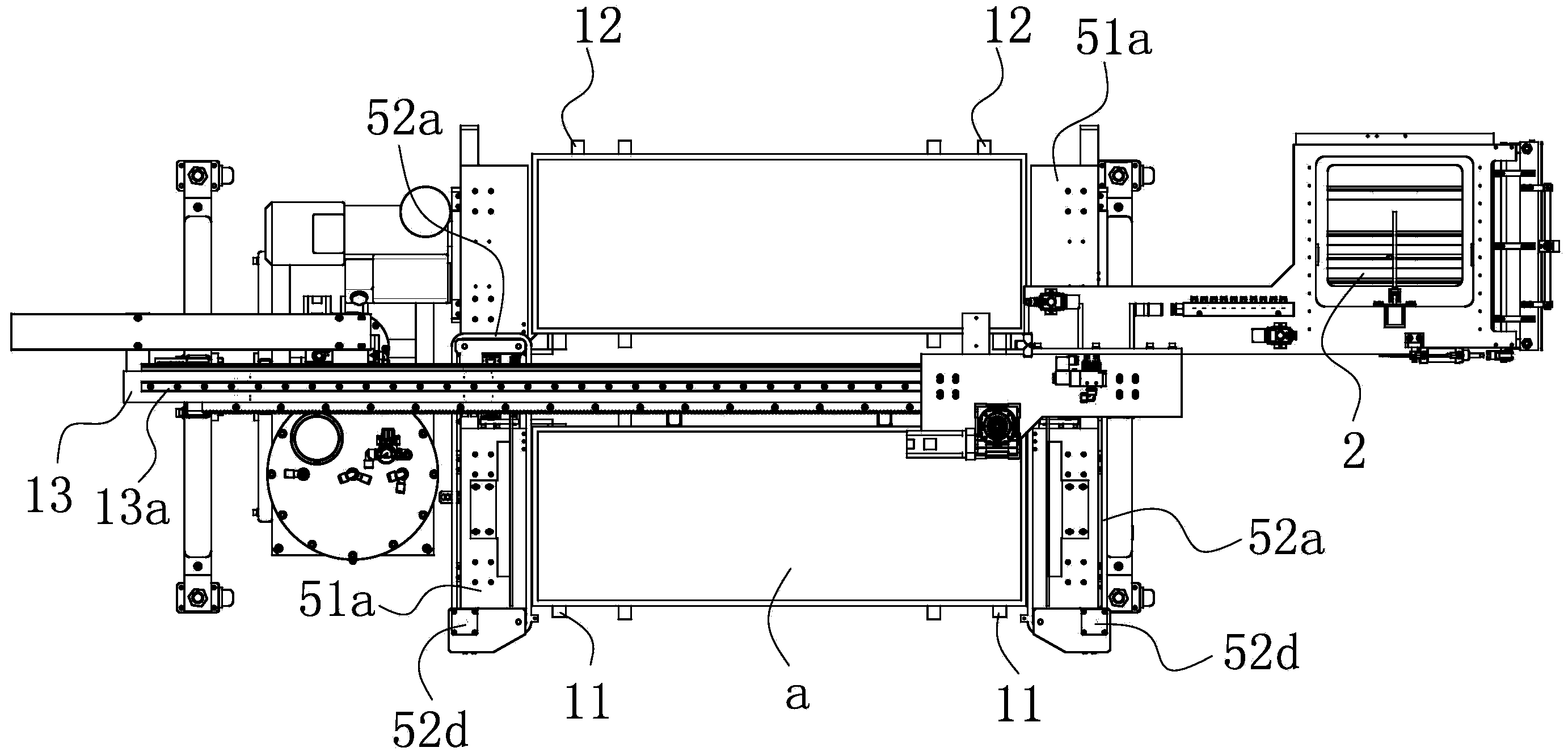

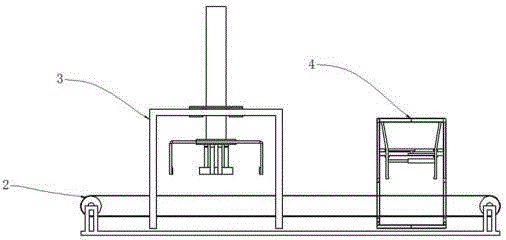

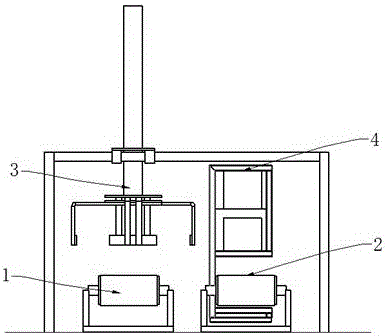

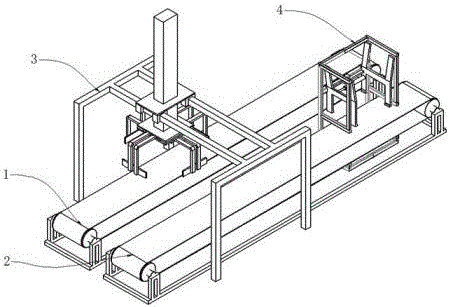

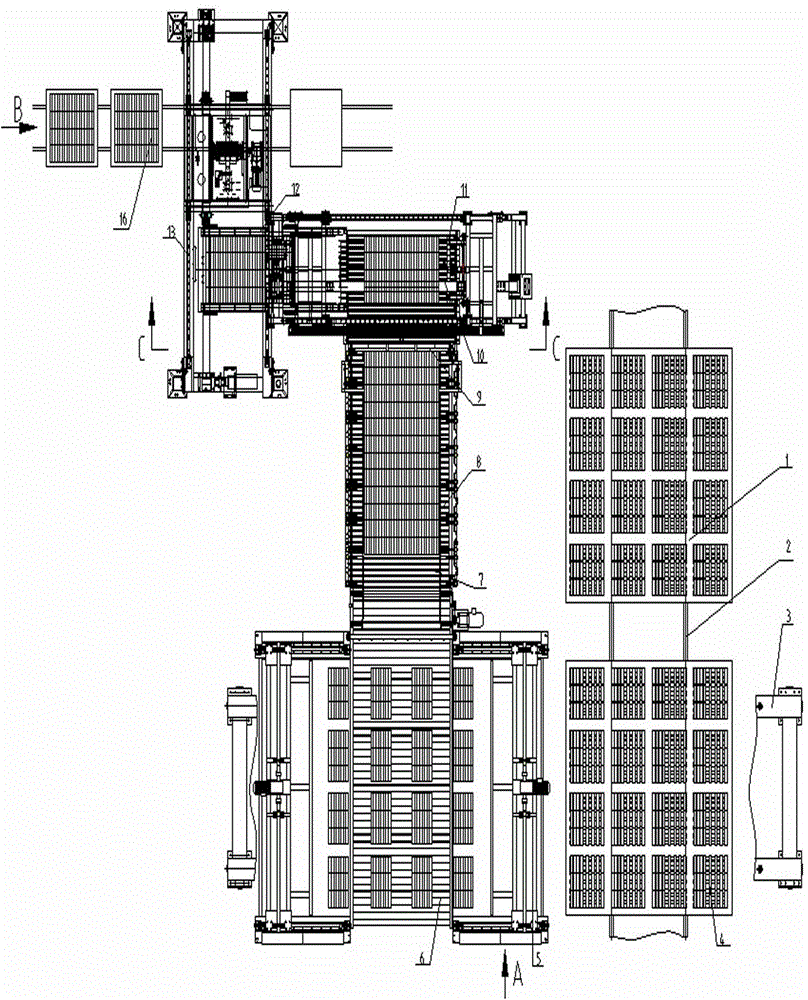

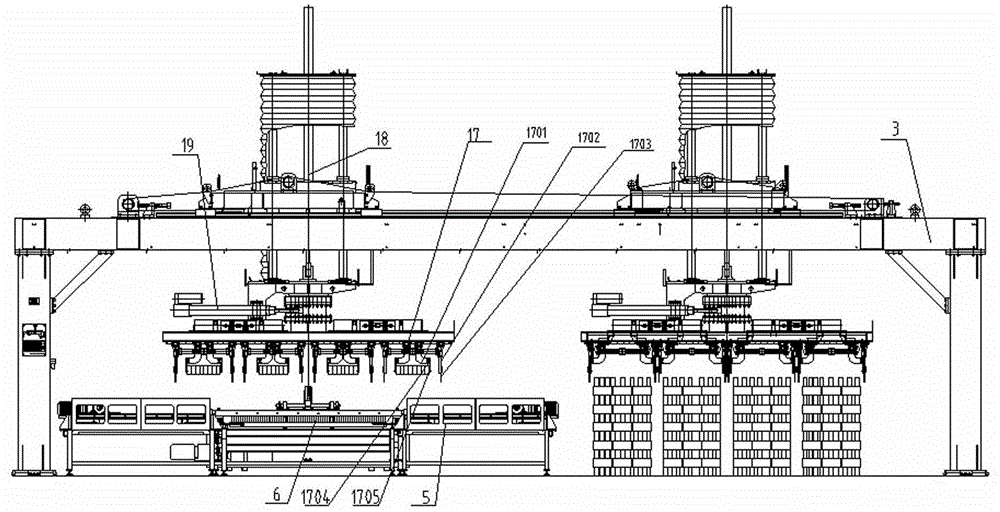

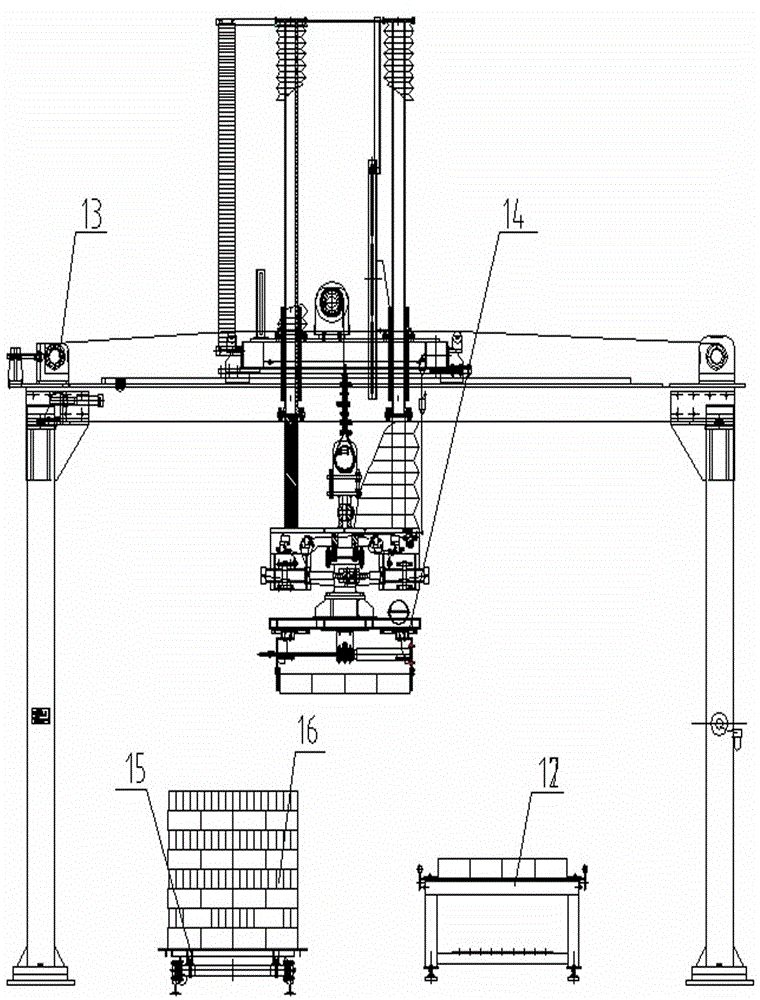

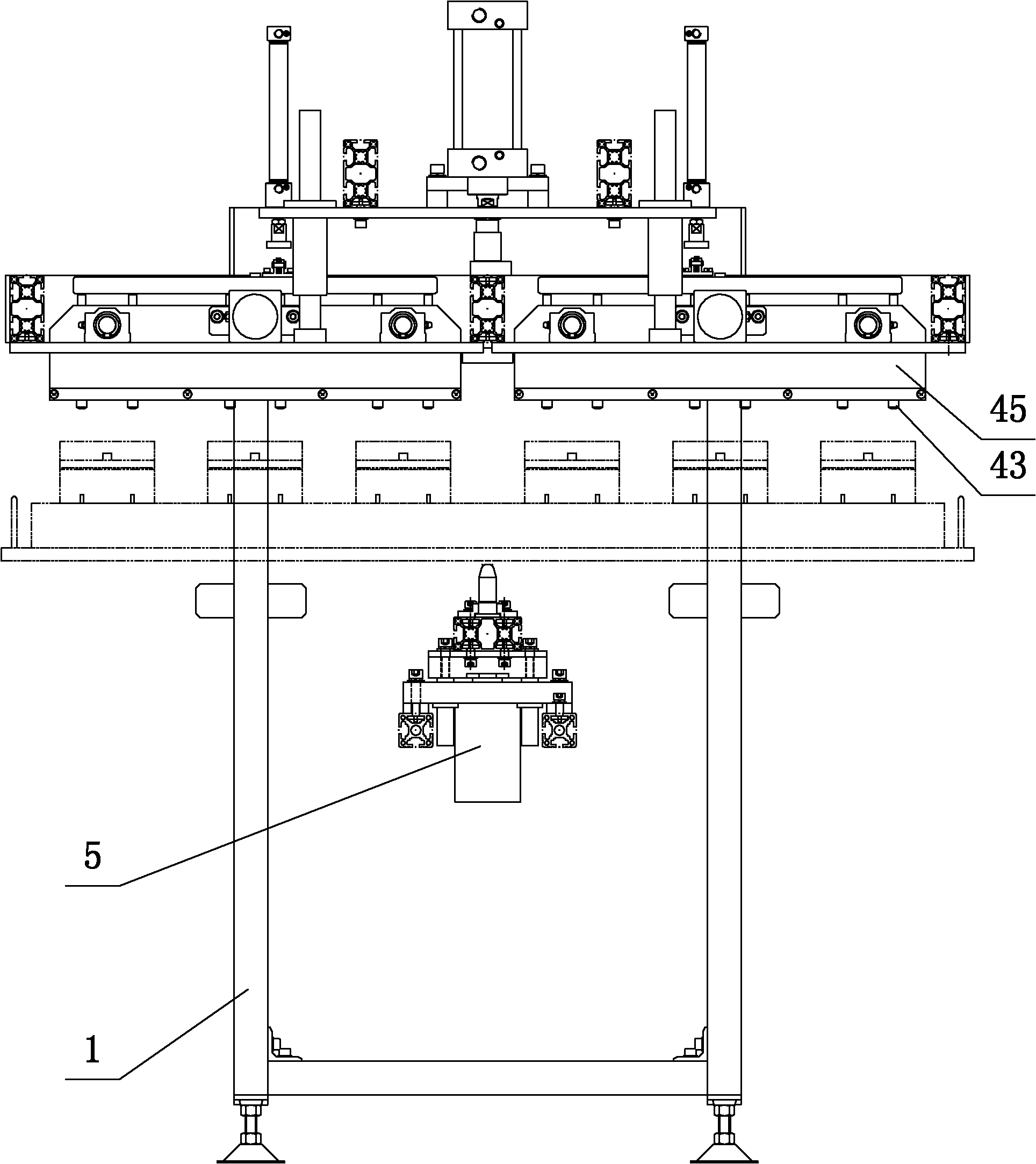

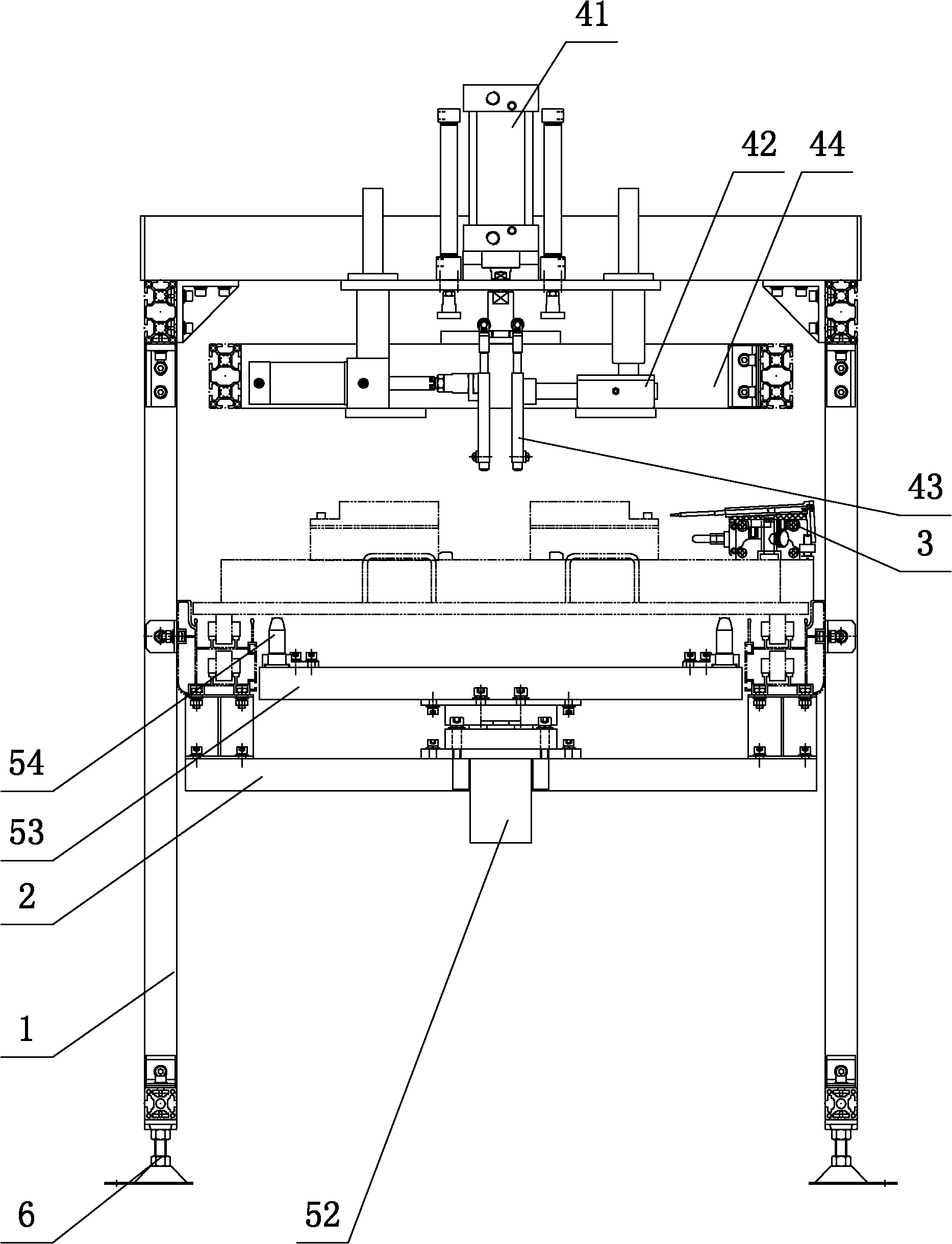

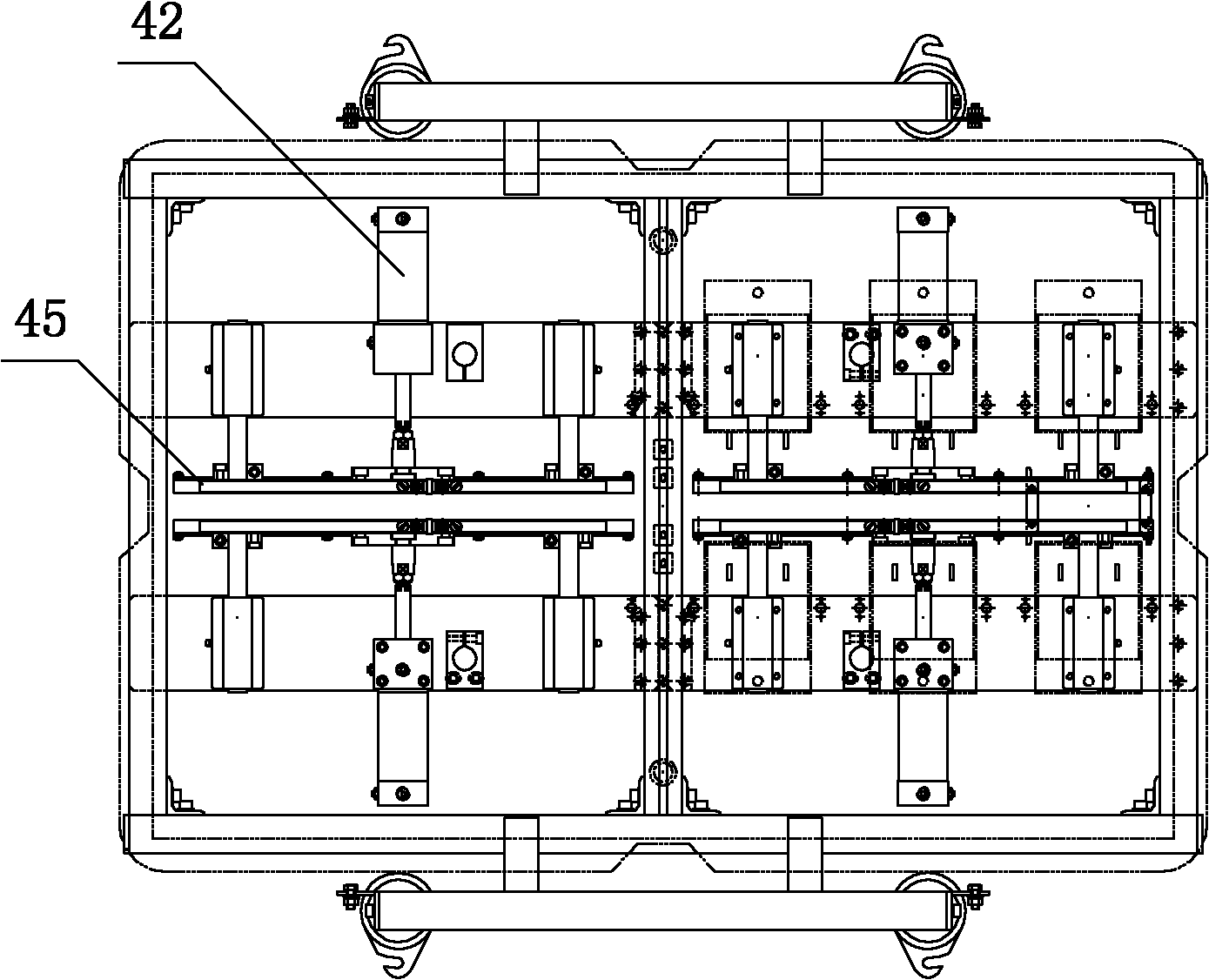

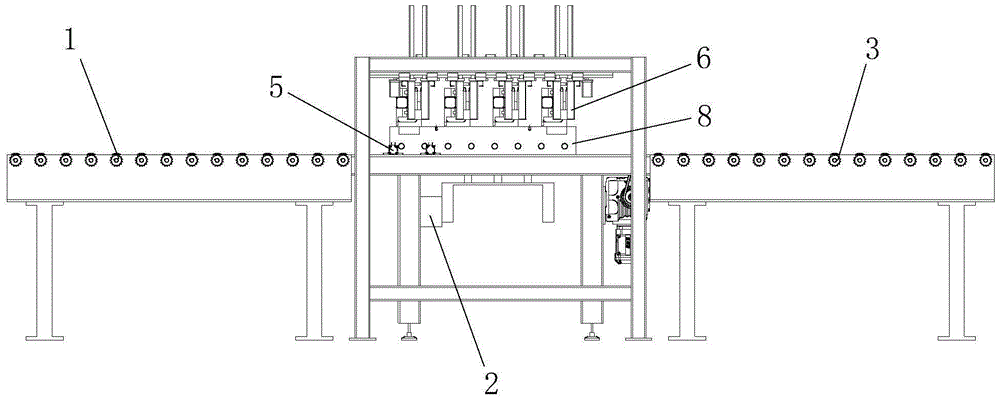

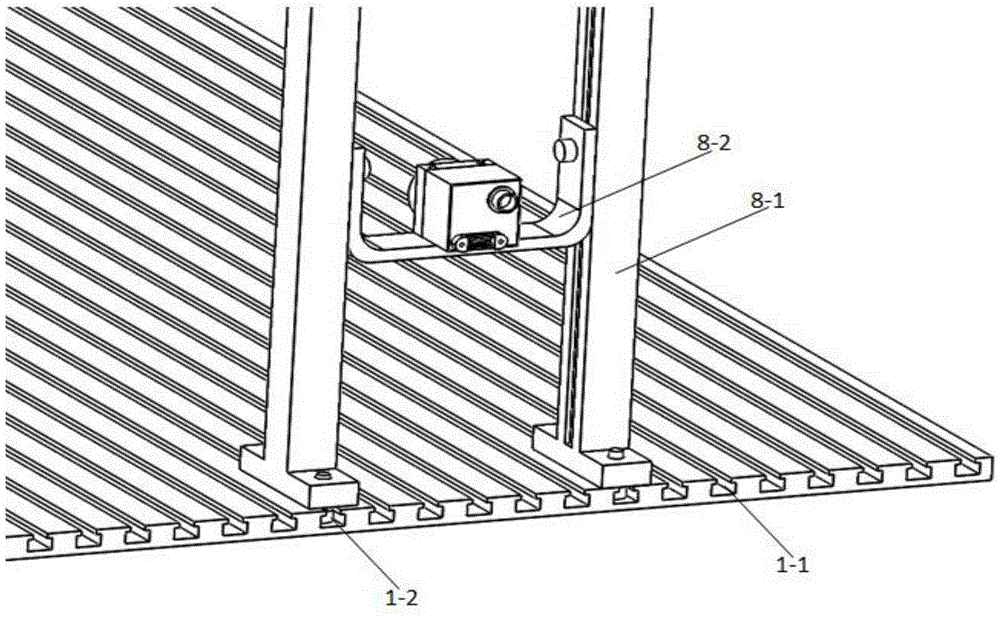

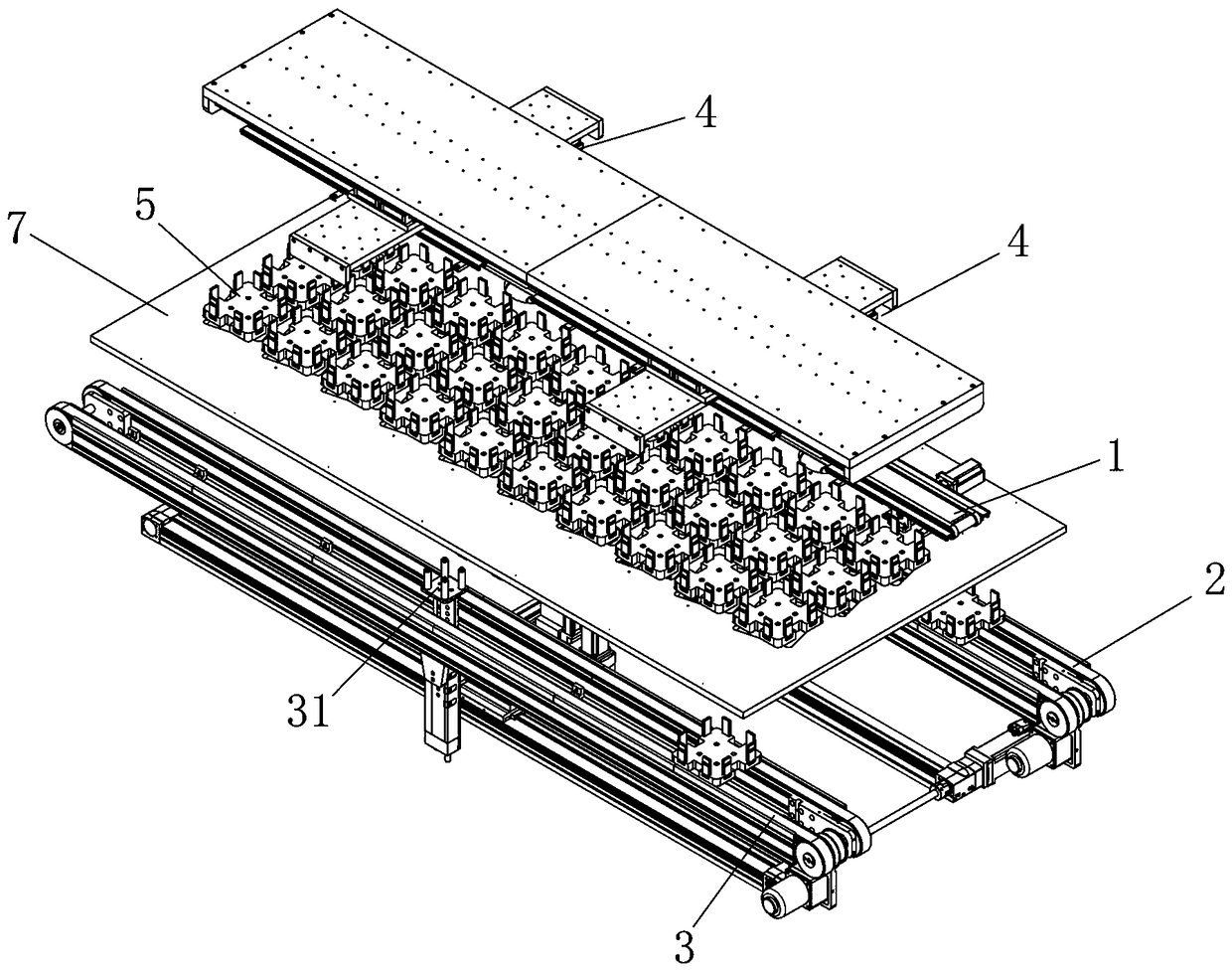

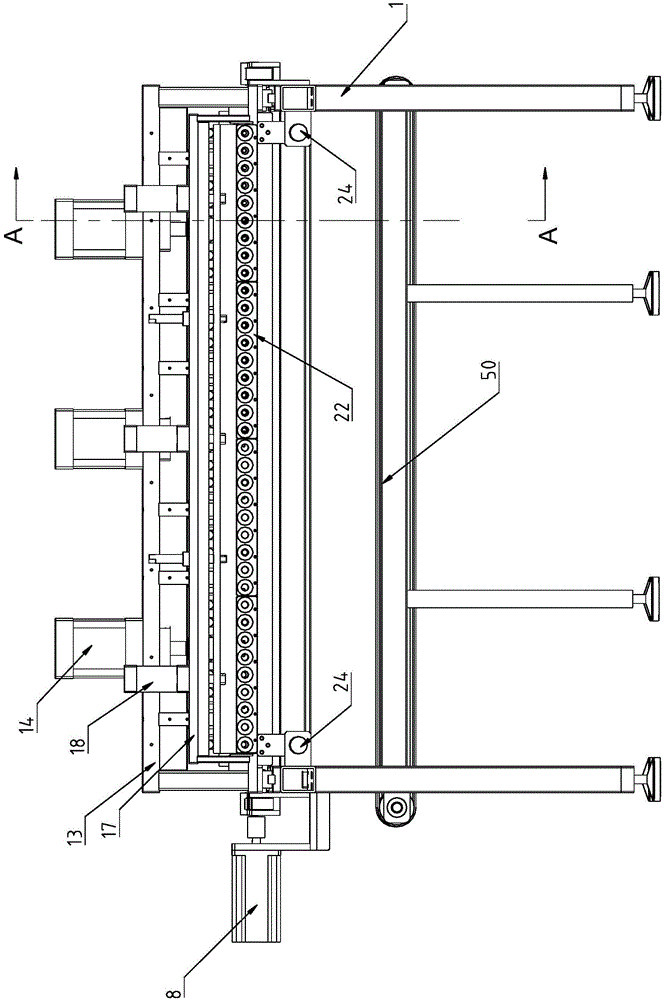

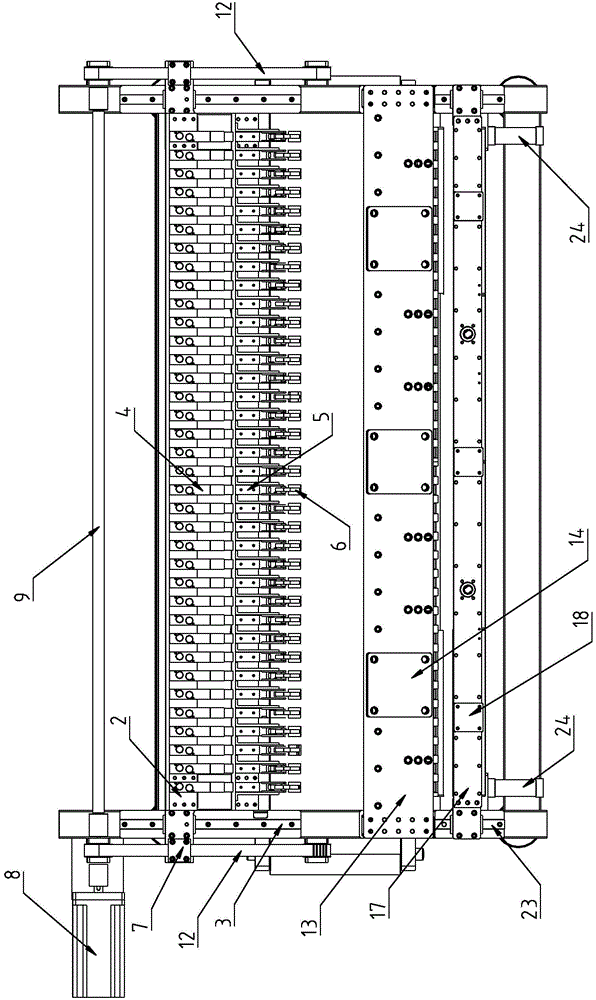

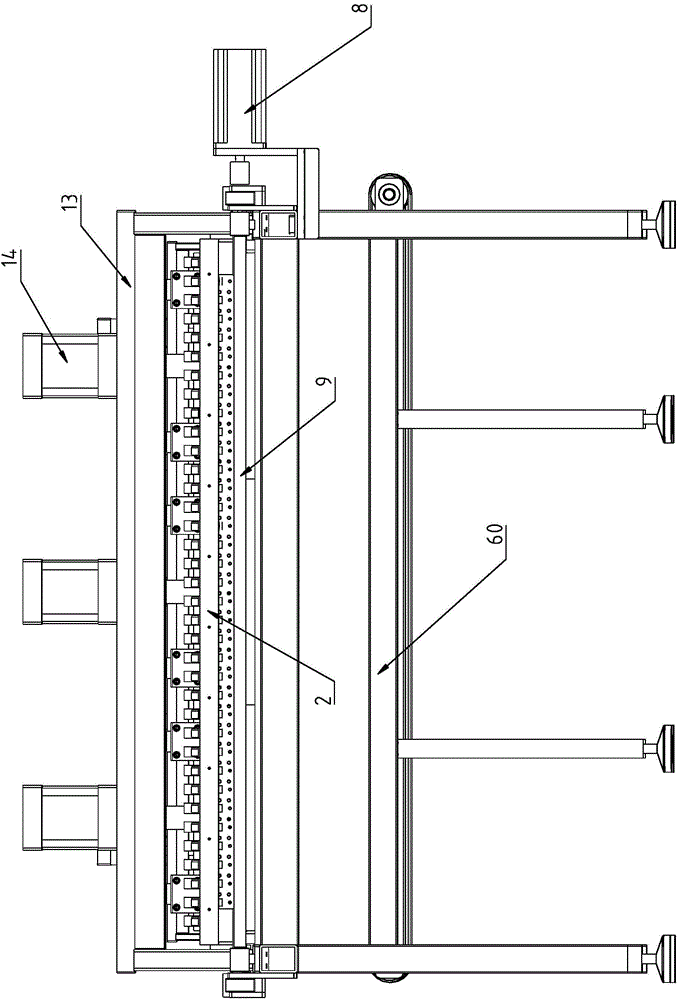

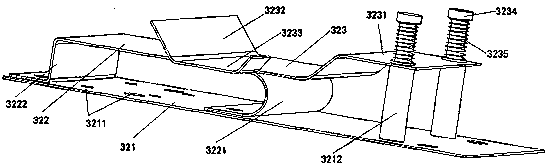

A brick unloading and palletizing unit for sintered bricks and a brick unloading and palletizing method

ActiveCN103552832BSolve bonding problemsReduce labor intensityStacking articlesDe-stacking articlesBrickPalletizer

A brick unloading and stacking unit and a brick unloading stacking method for sintered bricks, which are provided with a brick unloading machine for unloading the sintered bricks from the kiln car layer by layer and a pushing mechanism for horizontally gathering the bricks, followed by The connected first roller conveying platform is equipped with a device for aligning bricks longitudinally. A transfer device is provided above the roller conveying platform for conveying the grouped bricks forward in a direction perpendicular to the conveying direction of the first roller conveying platform, and a brick collecting platform is provided at the end of the second roller conveying platform. Above the brick platform, there is a palletizer for clamping and stacking the bricks on the brick collecting platform. The invention realizes the fully mechanized process from unloading to stacking, and effectively overcomes the bonding problem caused by deformation of bricks after sintering, thereby meeting the requirements of automatic production and greatly reducing labor intensity and production cost of workers.

Owner:洛阳曜辰自动化科技有限公司

Terminal combined type automatic wire connecting and disconnecting device for electric energy meter

ActiveCN102095910AMeet the requirements of automated productionIncrease productivityTime integral measurementAssembly lineEngineering

The invention discloses a terminal combined type automatic wire connecting and disconnecting device for an electric energy meter, which comprises a machine frame, a supporting plate, a tool positioning device and an electric energy meter moving device, wherein the tool positioning device is arranged on the supporting plate; the supporting plate is arranged on the middle part of the machine frame;the electric energy meter moving device is arranged on the upper part of the machine frame; and a wire plug device is arranged on the end part of the machine frame. The invention has the advantages that: the device can be applied to an automatic assembly line directly, can perform compression joint and wire disconnection on a plurality of electric energy meters simultaneously, can be locked automatically, does not need additional loads after being locked, meets the requirement of the automatic production of the electric energy meter, and improves the production efficiency greatly.

Owner:ZHEJIANG HOUDAR INTELIGENT TECH CO LTD

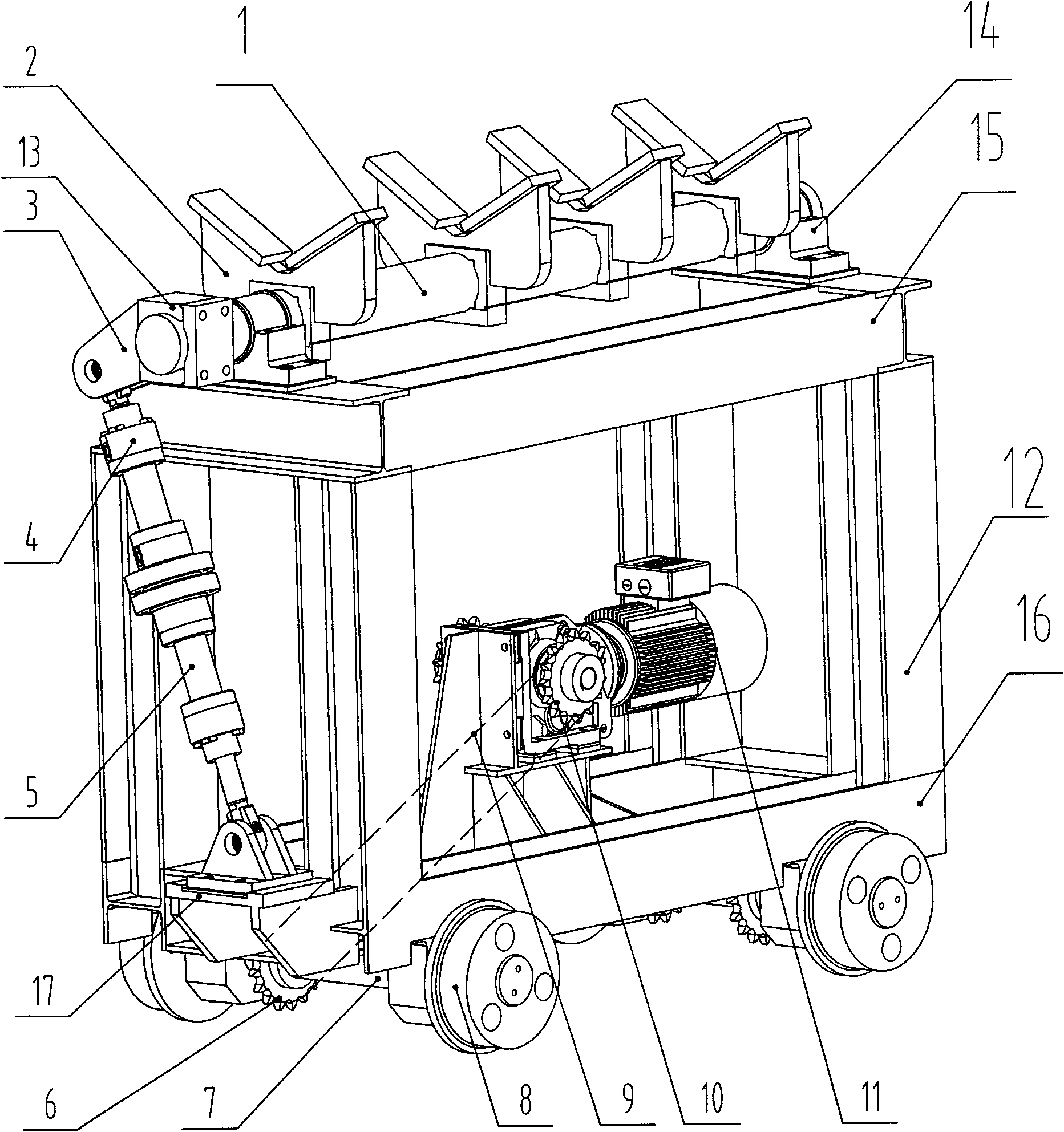

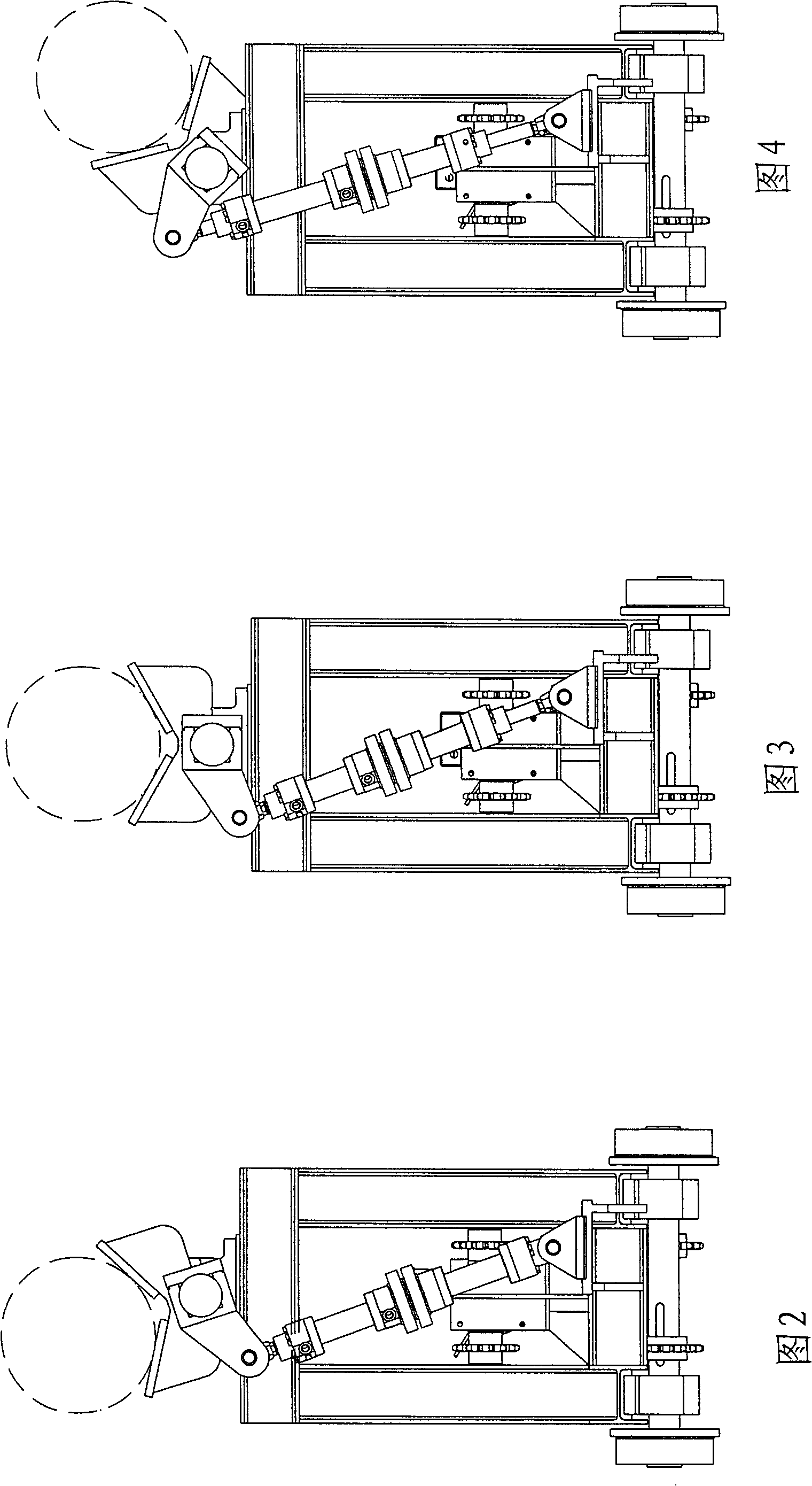

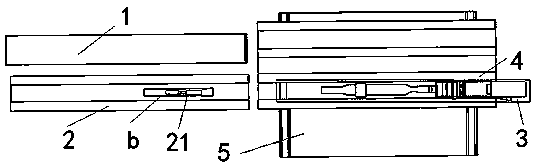

Blank automatic loading and unloading travelling bogie

ActiveCN101357638AMeet the requirements of automated productionOvercoming technical issues with scratchesCarriagesElectric machinerySteel tube

The invention pertains to equipment in seamless steel tube production, which relates to a travelling bogie that can automatically load and unload stock and solves the problems that the transportation automation degree of the stock in an extrusion steel tube workshop is low and the surfaces of steel tubes are easily scratched. The equipment comprises a travelling bogie body (12); a lower bracket of the travelling bogie body (12) is provided with a motor and a speed reducer (11); a driving chain wheel (10) is arranged on an outputting shaft; a driven chain wheel (6) is fixedly arranged on a wheel shaft (7); the driving chain wheel (10) drives the driven chain wheel (6) and the wheel shaft (7) to rotate by a chain (9); the end part of the lower bracket (16) is provided with a hydraulic oil cylinder (4) and a hydraulic oil cylinder (5) which are connected in series; a rotating shaft (1) is arranged on an upper bracket (15); a V-shaped silo (2) is fixedly arranged on the rotating shaft (1); the front end of the rotating shaft (1) is fixedly provided with a swing arm (3) which is articulated with an outputting shaft of the hydraulic oil cylinder (4). The equipment of the invention meets the requirements on the automation production of the whole stock production line.

Owner:TAIYUAN TONGZE HEAVY IND

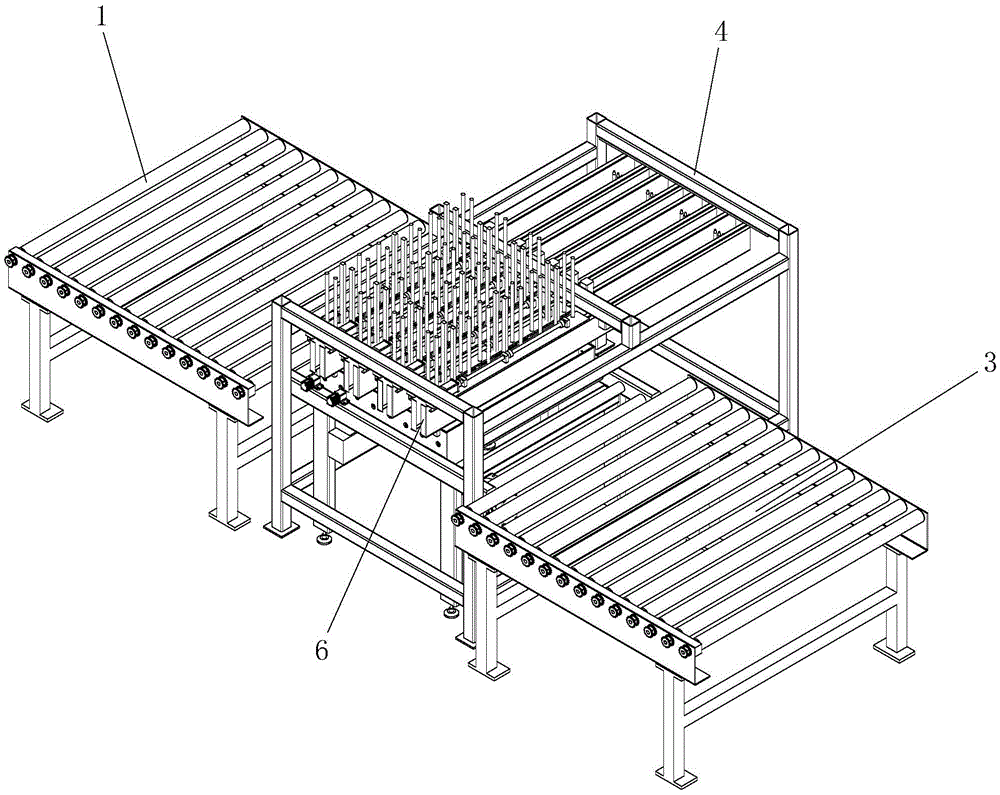

Glass wool filling device

InactiveCN105523231AAutomate operationMeet the requirements of automated productionPackagingGlass woolControl theory

The invention discloses a glass wool filling device. The glass wool filling device comprises a first conveying roller way, a servo lifting mechanism, a second conveying roller way and a servo pushing mechanism; the first conveying roller way is connected with the second conveying roller way through the servo lifting mechanism, and the servo pushing mechanism is located on the side face of the servo lifting mechanism; meanwhile, a positioning air cylinder and a servo pressing mechanism are arranged on the top of the servo lifting mechanism; and a servo adjusting mechanism is arranged on one side, close to the servo lifting mechanism, of the inner side of the servo pushing mechanism. Due to adoption of the technical scheme, wooden boxes can be accurately positioned on the position to be filled through the servo lifting mechanism, and therefore automatic operation of the filling technology is achieved; the filling device can be suitable for glass wool and the wooden boxes of different models, and free matched filling of the glass wool and the wooden boxes can be achieved according to production requirements; and therefore the filling device has the beneficial effects that the application range is wide, the production efficiency is high, the production cost is saved, and the harm to the human body is reduced.

Owner:WECAN M&E SHANGHAI

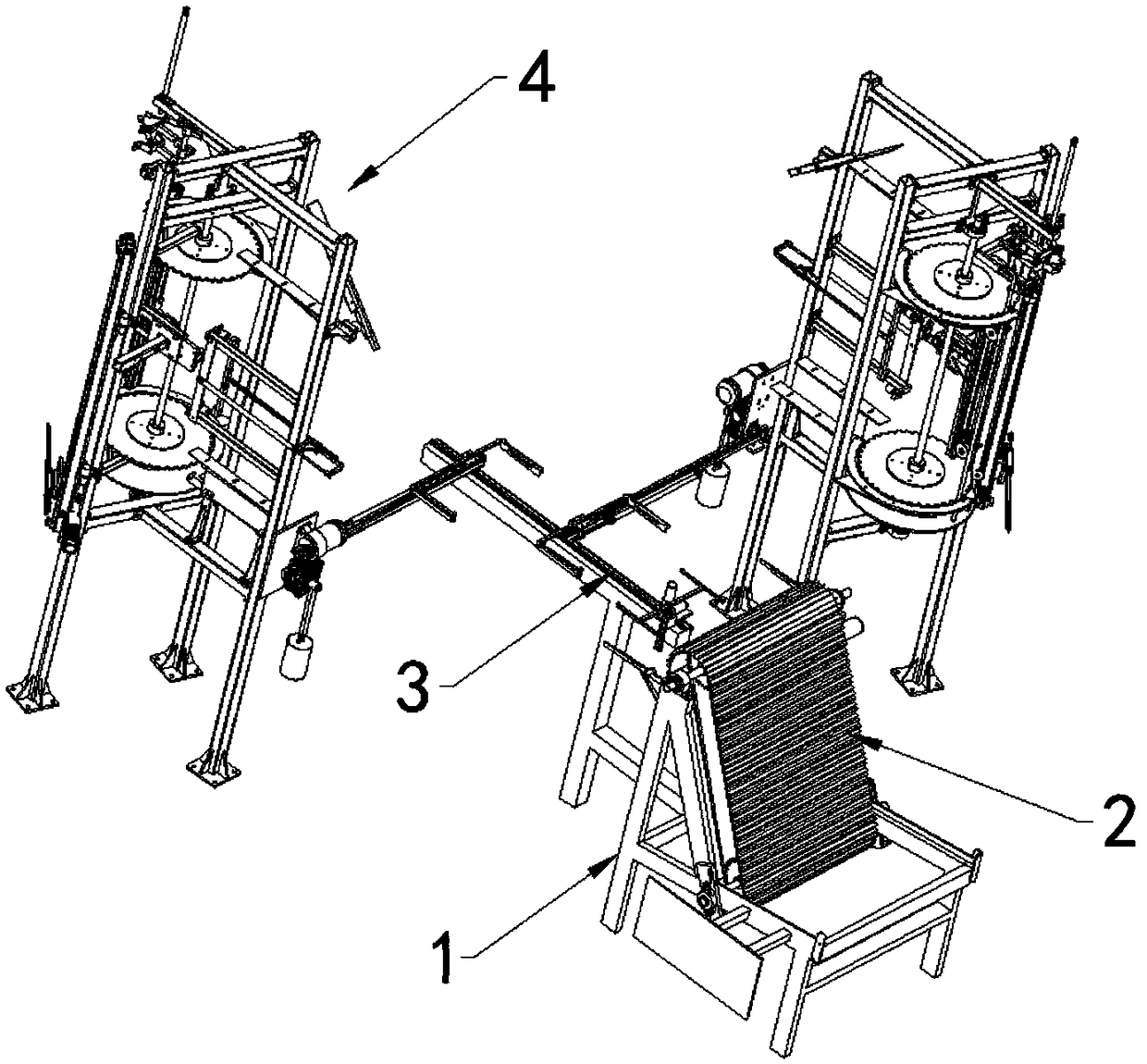

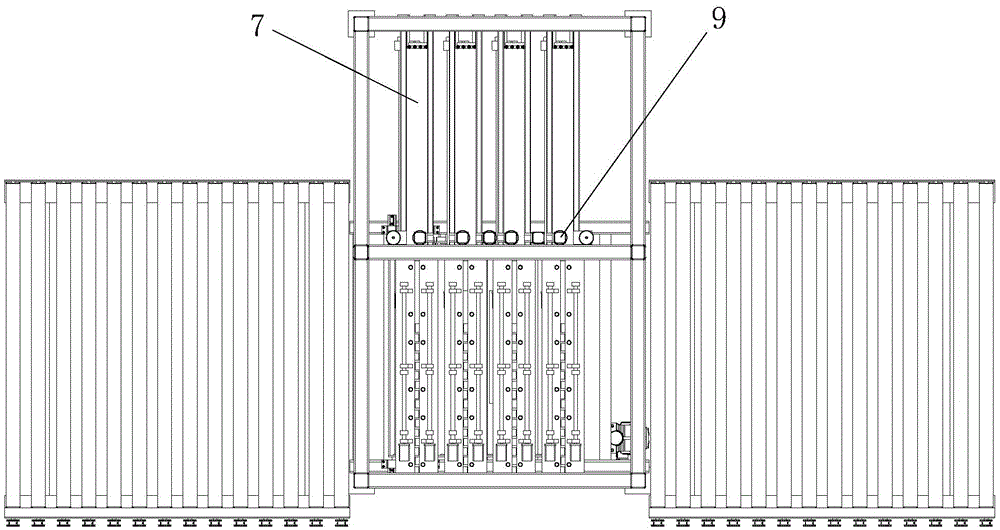

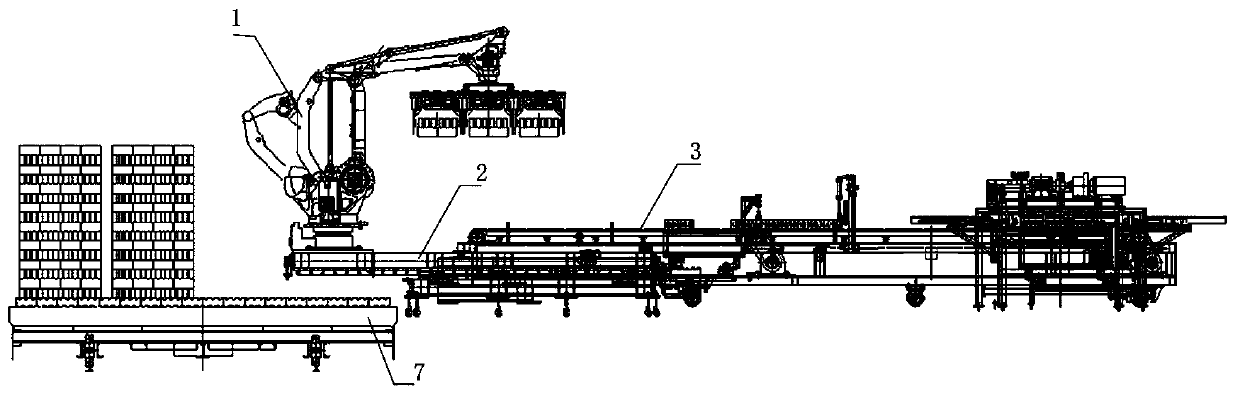

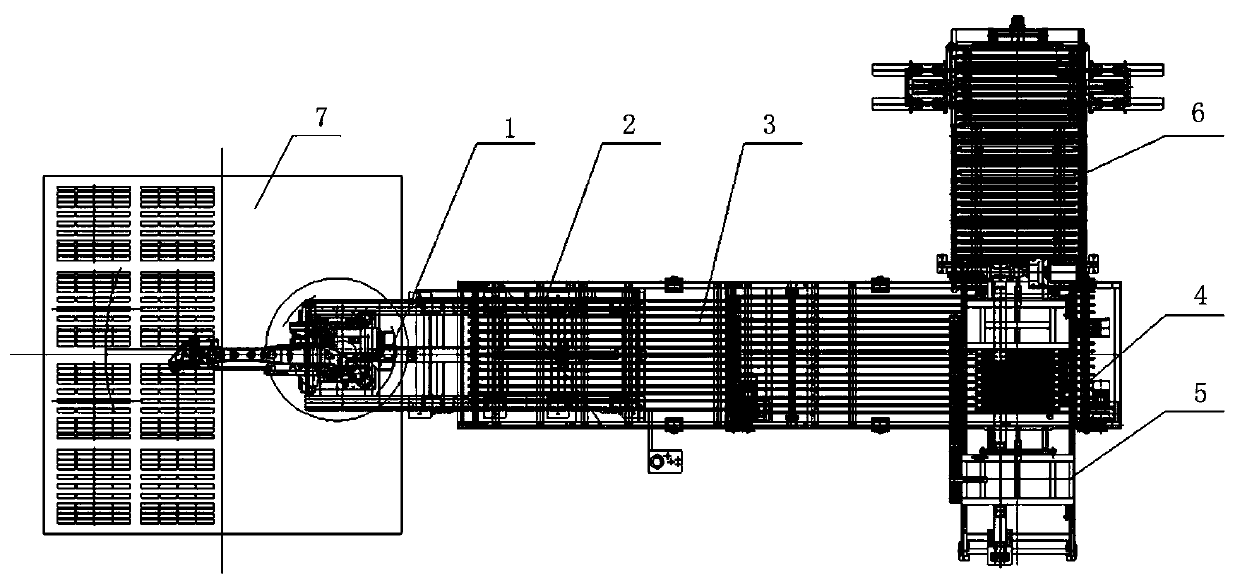

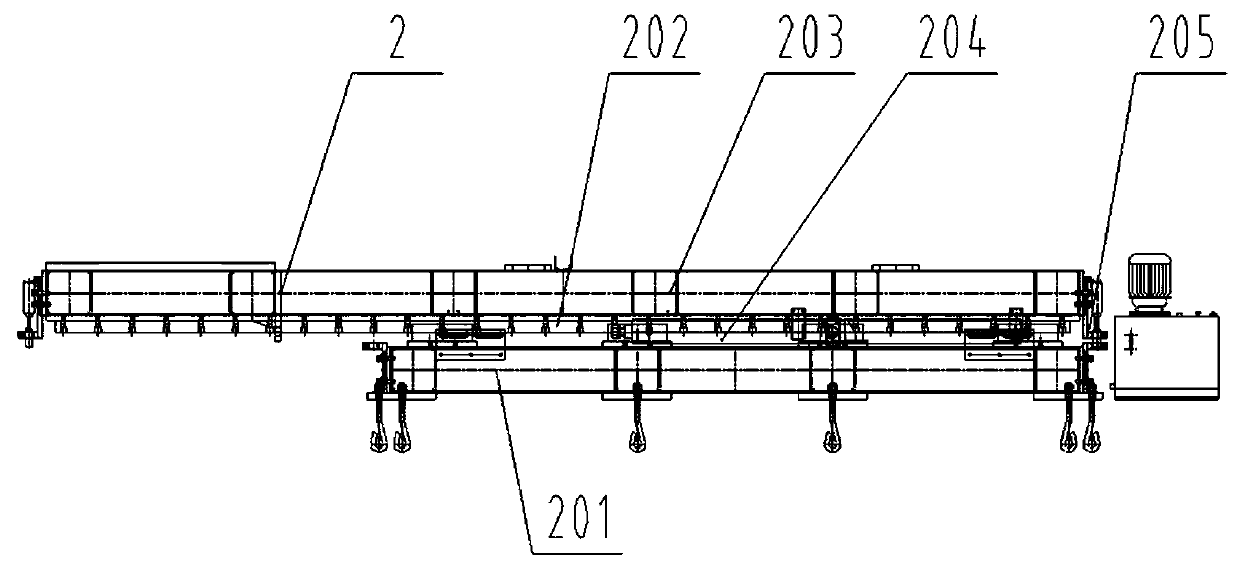

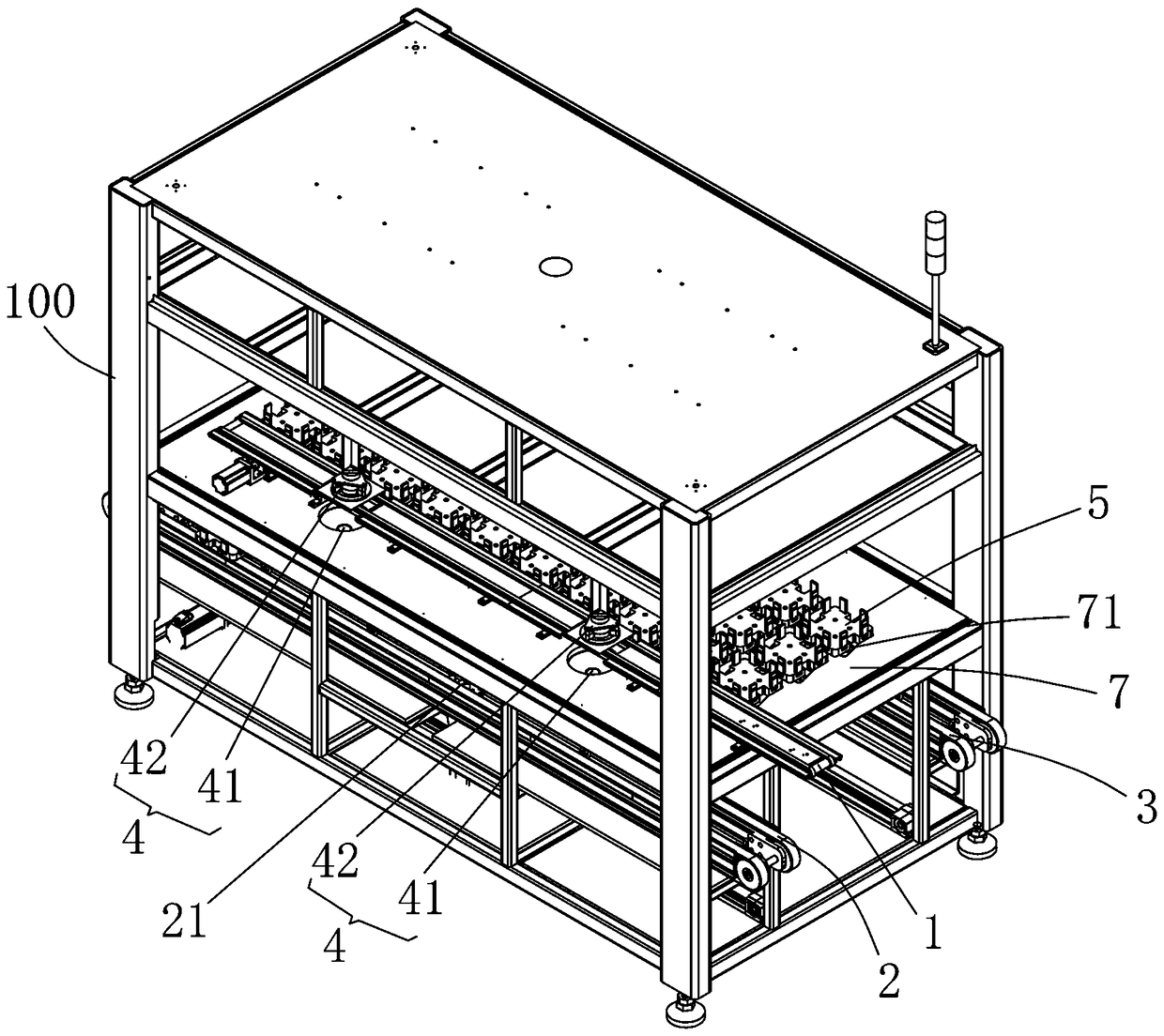

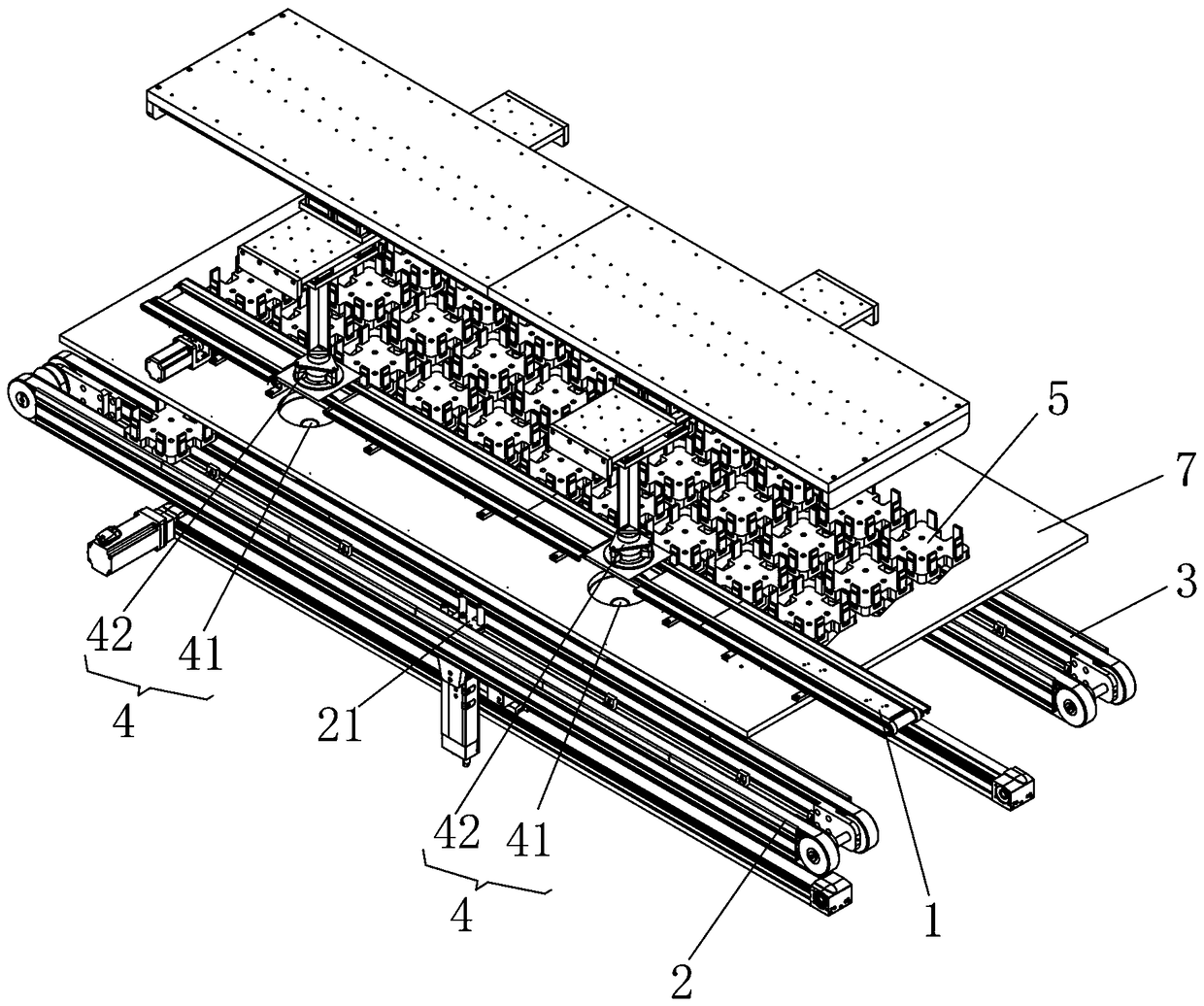

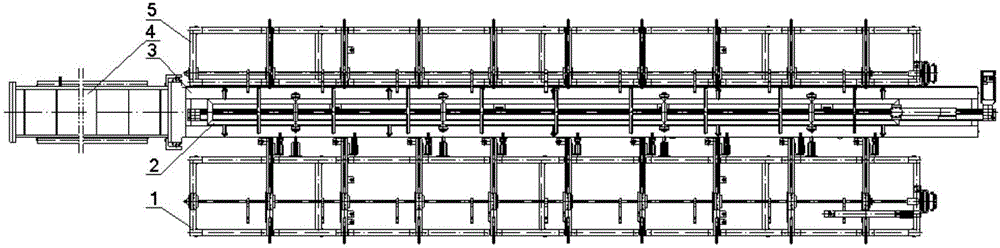

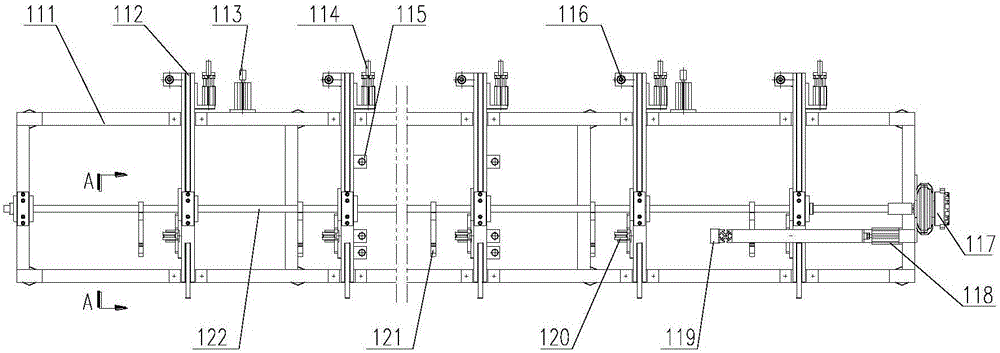

Robot brick unloading and grouping device and method of sintered bricks

PendingCN109552893ABreak down the difficulty of unloading bricksIncrease productivityControl devices for conveyorsStacking articlesMechanical ProcessesEngineering

A robot brick unloading and grouping device of sintered bricks comprises a brick unloading robot, a conveying and grouping device and a brick collection device. The brick unloading robot is mounted ona moving device, and multi-station brick unloading of the brick unloading robot on a kiln car is achieved. The moving device and the conveying and grouping device are fixedly connected, and synchronous multi-station motion is achieved. A lifting roller way device ascending and descending in a conveying face gap is fixedly arranged below the conveying and grouping device so as to lift to-be-stacked finished bricks, and the lifted finished bricks are conveyed to the brick collection device in the direction perpendicular to the conveying direction of the conveying and grouping device to wait forbeing clamped by a stacker. By means of the device and a corresponding brick unloading and grouping, the finished bricks can be unloaded from brick stacks of the kiln car layer by layer in a subregion manner, then the finished bricks are grouped, and the requirement of the full mechanical process of stacking is met.

Owner:中建材(洛阳)节能科技有限公司 +1

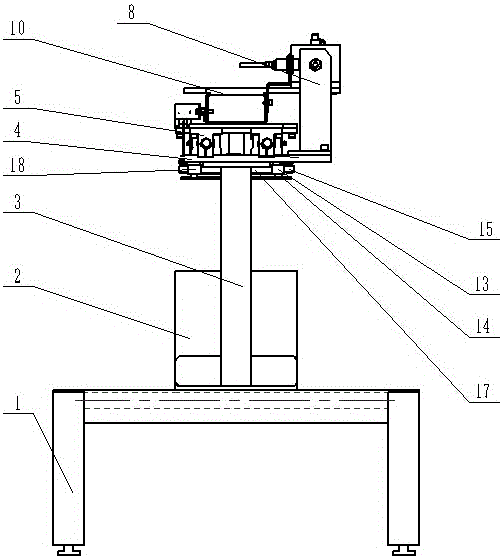

Machine vision-based online detection device of sizes of small-type and mini-type shaft parts

InactiveCN105403155AImprove adaptabilitySolve the problem of fixed singularityUsing optical meansMicrocontrollerReduction drive

The invention discloses a machine vision-based online detection device of sizes of small-type and mini-type shaft parts. The device mainly comprises a pedestal, a movable camera support, a motor, a speed reducer assembly, a rotation light source detection disc and a control part. The motor and the speed reducer assembly are installed on the pedestal. The rotation light source detection disc is connected with the speed reducer assembly via a bearing and a coupling. The core of the control part is a single-chip microcomputer. The rotation light source detection disc is the core of the whole detection device, and comprises a detection housing body, an LED light source, a light guiding plate, a reflection plate, a light diffusion plate and an object carrying plate. The light source is embedded into the detection device, so the integrality of the device is improved. The objective of the invention is to solve the problem that current detection means of for sizes of small-type and mini-type shaft parts do not meet automatic production requirements in the modern industry. According to the invention, non-contact online monitoring can be achieved; problems of low-efficiency and non-automation of manual measurement can be solved; and quite high measurement precision and quite fast measurement speed can be achieved, thereby greatly increasing measurement efficiency.

Owner:CHINA JILIANG UNIV

Material receiving device suitable for silicon wafer production line

PendingCN108538772AReduce labor costsReduce secondary damageSemiconductor/solid-state device manufacturingConveyor partsEngineeringProduction line

The invention relates to a material receiving device suitable for a silicon wafer production line. The material receiving device is provided with a silicon wafer conveying belt, an empty tray conveying belt, a full tray conveying belt, a visual inspection and alignment mechanism and multiple material receiving trays. The material receiving trays are put in the set area and perform automatic loading and unloading through a loading and unloading mechanism. The empty tray conveying belt provides the empty material receiving trays to the loading and unloading mechanism. The full tray conveying belt receives the material receiving trays fully loaded with the silicon wafers and unloaded by the loading and unloading mechanism. The visual inspection and alignment mechanism is arranged along the material feeding direction of the silicon wafer conveying belt. The visual inspection and alignment mechanism picks up the silicon wafers conveyed by the silicon wafer conveying belt to perform inspection and alignment and then put the silicon wafers in the corresponding material receiving trays. The material receiving device is suitable for the silicon wafer production line, meets the requirementsof automatic production and can perform online automatic detection and material receiving and automatic screening and alignment so that the manual cost can be reduced, the secondary damage can be reduced and the efficiency can be enhanced, and self-inspection is performed in material receiving and thus the situation that the poor products are mixed in the qualified products can be avoided; and thestructure is simple and scientific and reasonable so that the operation rate and the operability of the silicon wafer production line can be greatly enhanced and industrial use can be met.

Owner:FOLUNGWIN AUTOMATIC EQUIP CO LTD

Firework powder mixing-loading device

ActiveCN104197789AMeet the requirements of automated productionEnsure consistencyFireworksManufacturing technologyControl system

The invention provides a firework powder mixing-loading device which comprises a motor, a powder mixing cylinder, a supporting roller, a temporary storage cabin, an air cylinder guiding rod, a guiding shaft, a powder compensation pipe, a powder pressing plate, a powder pushing plate, a measuring plate, a control system and the like. The processes of powder mixing and loading are completed through the control system, and man-machine separating is achieved. The firework powder mixing-loading device is suitable for the technical field of firework manufacturing. After grouping of a plurality of firework powder cylinders at the same time, automatic powder loading can be carried out, powder mixing and loading on-site non-person operation is achieved, potential safety hazards are reduced, the device can be combined with a logistics line, the whole automatic production requirement of a firework manufacturing technology can be met, the consistency and the accuracy of powder loading amount are guaranteed, and powder loading accuracy is smaller than or equal to 3%.

Owner:中国兵器装备集团自动化研究所有限公司

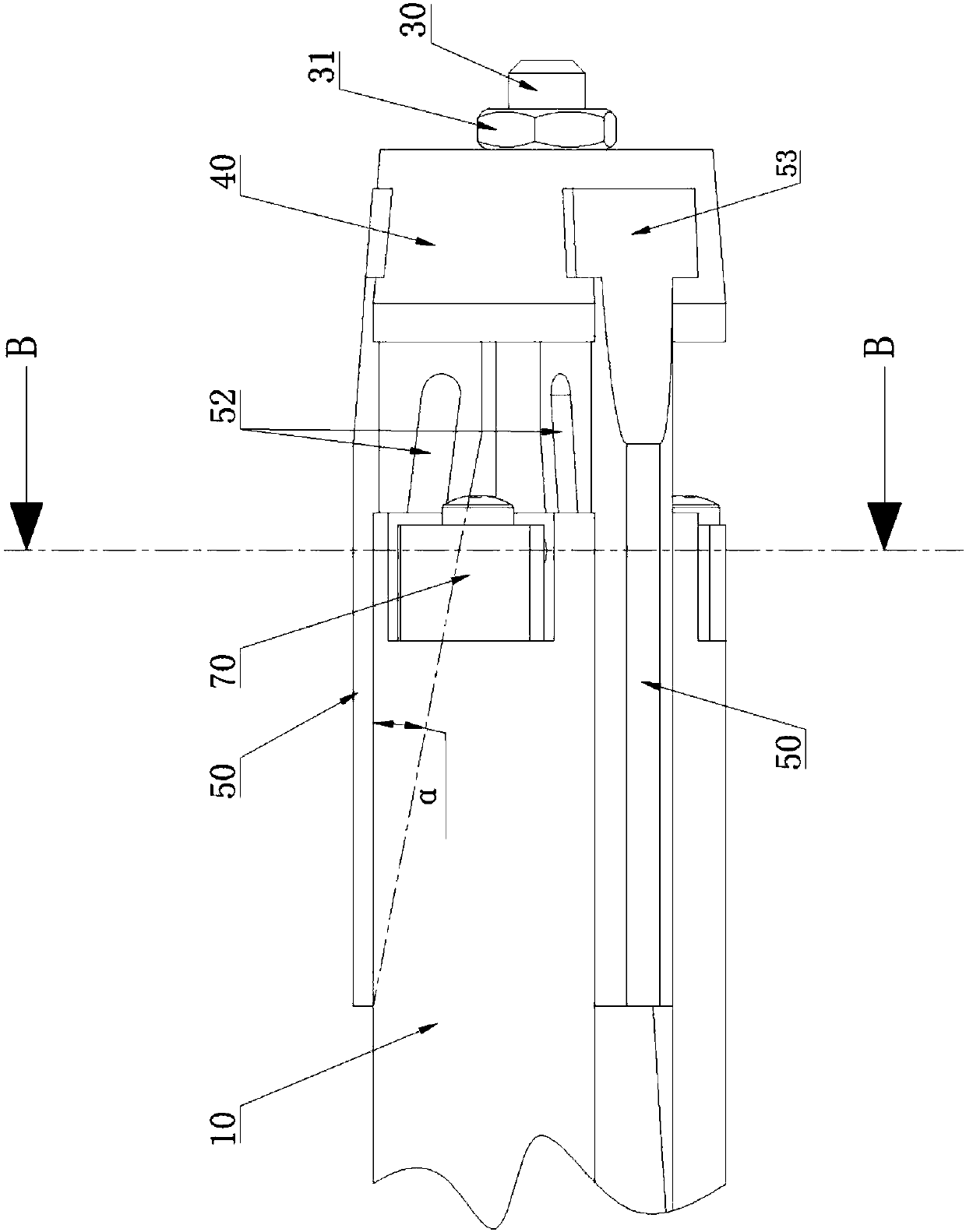

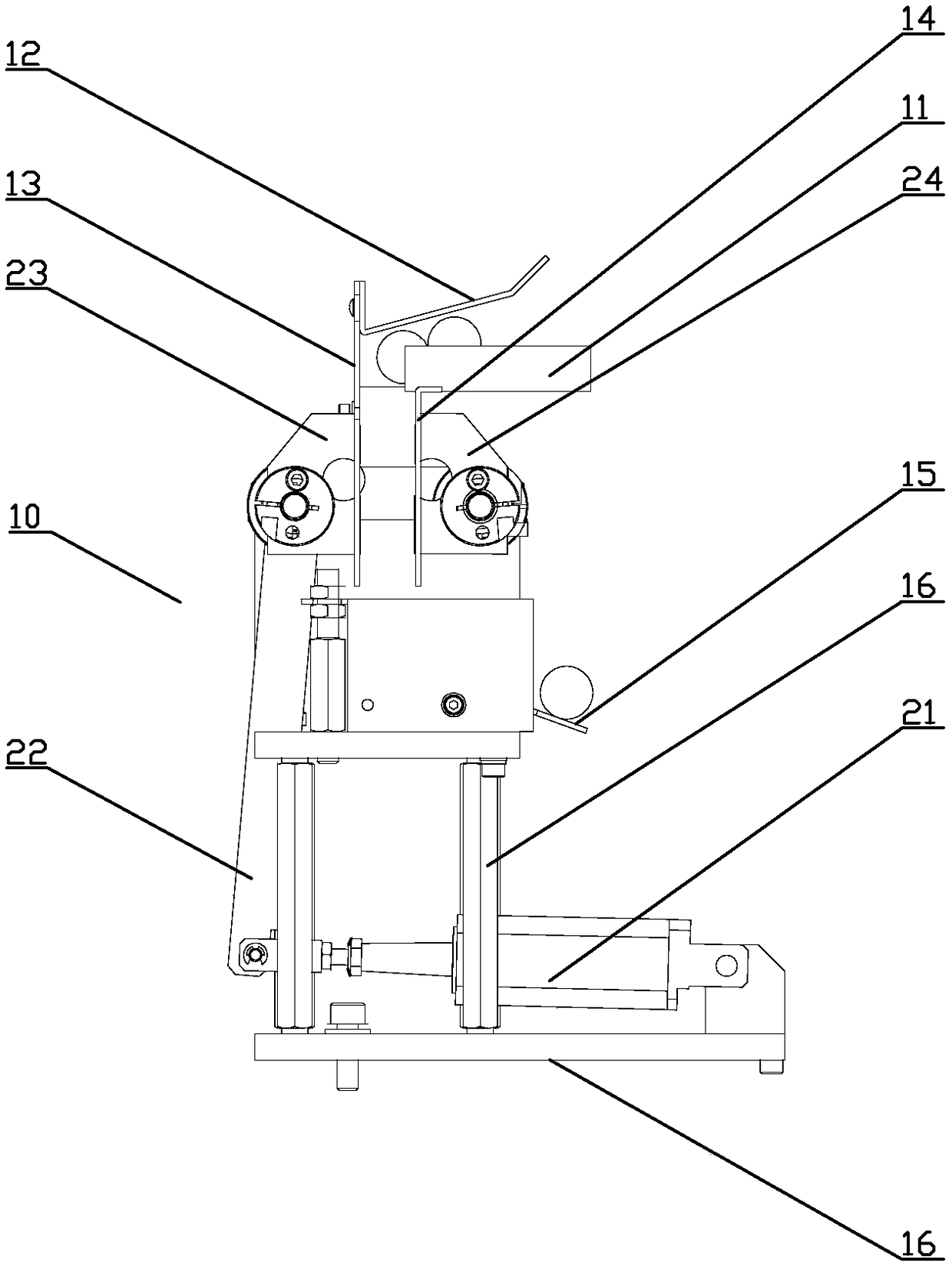

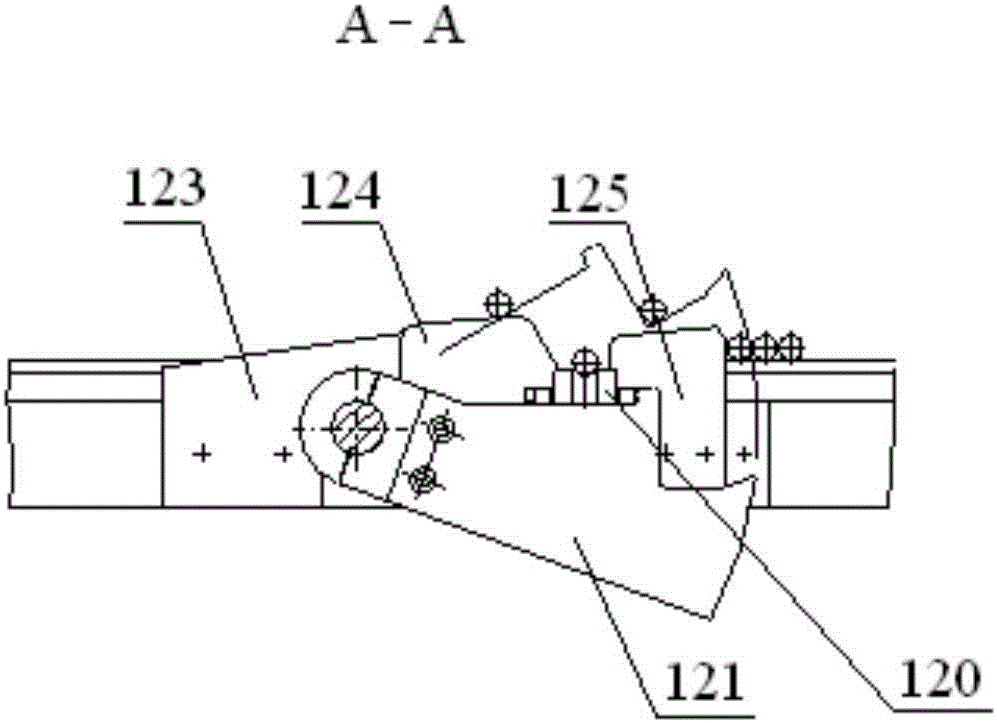

Sintered brick unloading manipulator device

PendingCN109552895AImprove versatilityImprove adaptabilityStacking articlesDe-stacking articlesBrickEngineering

The invention discloses a sintered brick unloading manipulator device which comprises a hanging bracket and a plurality of clamp hand units installed at the bottom of the hanging bracket, wherein a connection bracket is arranged at the top end of each of the clamp hand units and is installed at the bottom of the hanging bracket through a flexible device; a limiting position for limiting a clampingheight of each of the clamp hand units is additionally installed on the connection bracket; and an inclined acting force generated by sintered piled bricks to a limiting plate is overcome through thedeformation of the flexible device in the process of fitting the limiting plate and the upper surfaces of the sintered piled bricks. In the sintered brick drawing and unloading process, all unit clamping piece groups are flexibly connected, the deformed piled bricks are positioned through the limiting device to determine a deformation direction, and a relative position between each unit clampingpiece and the brick body to be clamped in the deformed piled bricks is automatically adjusted by each unit clamping piece group to guarantee the stable and reliable clamping process, so that the sintered brick unloading manipulator device realizes the unloading of the bonded, concave and aslant piled bricks, and meets the mechanical and automatic production requirement.

Owner:中建材(洛阳)节能科技有限公司 +1

Automatic welding device for automobile sealing pad

InactiveCN106425175AHigh degree of automationGuarantee product qualityWelding/cutting auxillary devicesAuxillary welding devicesElectrical controlEngineering

The invention discloses an automatic welding device for an automobile sealing pad. The automatic welding device comprises a machine body (1) and is characterized in that the machine body (1) is provided with a feeding device (2), a detection device (3), an electrical control device (9), a servo positioning welding device (4), a material beating device (7), a discharging device (5) and a material pressing device (8); a rotary workbench (10) is arranged at the center of the machine body (1) and provided with a movable positioning pin device (6); and all the devices are connected with a transmission device, and an electrical element is connected with an air pipeline and the electrical control device (9). The technology steps of product combining, positioning, detecting, welding, finished product taking, placing and stacking and the like are integrated on one device, automatic operation of the procedures of feeding, detecting, welding and discharging is finished, the automation degree is high, and compared with the original production technology, efficiency is improved to 3-4 times. Meanwhile, the product quality is guaranteed, and the production cost is reduced.

Owner:YANTAI ISHIKAWA SEALING TECH CO LTD

Intermittent rod part collection device

The invention discloses an intermittent rod part collection device. The intermittent rod part collection device comprises a distribution mechanism achieving one-by-one sorting and a collection mechanism achieving intermittent collection. The distribution mechanism comprises a conveying channel assembly and an intermittent distribution assembly. The conveying channel assembly comprises a supportingplate, a limiting baffle, a left channel plate, a right channel plate, a flow guide plate and a support. The collection mechanism comprises a conveying belt and a vertical conveying assembly. The vertical conveying assembly comprises a fixed support, a second air cylinder and a rod supporting plate. The device further comprises a controller, and a first air cylinder, the conveying belt and the second air cylinder are all electrically connected with the controller. According to the intermittent rod part collection device, rod part products of a production line are arranged, workpieces are arranged in a containing box in order through the vertical conveying assembly, the fall of rod parts is eliminated, and damage generated when the workpieces fall into the containing box directly from theconveying belt is avoided; and control is simple, and automatic control of the whole device can be achieved through single variables.

Owner:TIANJIN SAIXIANG M&E ENG CO LTD

Carton centering mechanism of production line conveyor

The invention relates to a carton centering mechanism of a production line conveyor, and belongs to the field of mechanical and industrial automatic design. The carton centering mechanism comprises a swing arm I, an installing plate I, supports, sliding bearings, sliding shafts, a vertical plate, a both-way air cylinder, a top beam, an installing plate II, a swing arm II, a rack I, a supporting plate, a supporting plate fixing shaft, a gear and a rack II. Centering is carried out in the conveying direction of a production line on the conveyor. The centering mechanism finishes the transverse centering positioning along the production line. Under the premise that correction reference systems of conveying mechanisms among multiple stations are consistent, the same-level centering result of cartons can be kept among the multiple stations, it is expected to achieve the high centering precision, and the work efficiency of automatic production of the production line is correspondingly improved. The labor productivity can be greatly improved, labor intensity is lowered, the production cost is reduced, and the market competitive capacity of products is improved.

Owner:KUNMING UNIV OF SCI & TECH

Rotating plate type automatic loading machine for glass tubes

InactiveCN108726858AReduce labor costsMeet the requirements of automated productionGlass reforming apparatusGlass productionButt jointEngineering

The invention discloses a rotating plate type automatic loading machine for glass tubes. The rotating plate type automatic loading machine for the glass tubes comprises a rack, a glass tube overturning device, a pushing tube conveying device, a rotating plate separating device, a pushing tube inserting device, a blowing head and tube tail butt joint device and a blowing head lifting device, and the glass tube overturning device, the pushing tube conveying device, the rotating plate separating device, the pushing tube inserting device, the blowing head and tube tail butt joint device and the blowing head lifting device are separately mounted on the rack. During use, glass tubes from a previous procedure can be erected by the glass tube overturning device, then the glass tubes are conveyed into slots of an upper rotating plate and a lower rotating plate of the rotating plate separating device one by one through the pushing tube conveying device and are orderly arranged in a separated manner, then the glass tubes are conveyed into the pushing tube inserting device one by one by rotation of the rotating plate and are conveyed to positions above an object equipment clamp one by one, theglass tubes are in butt joint with blowing heads by the blowing head and tube tail butt joint device and then are conveyed into the object equipment clamp, before the glass tubes are in butt joint with the blowing heads, the blowing heads are lifted up in advance necessarily through the blowing head lifting device, and then, tube inserting actions are finished. Therefore, ordered production is implemented, a large number of labor costs are saved, requirements for automatic production are met, and the production efficiency is greatly improved.

Owner:黎泽新

Automatic shearing machine for pine branches of plastic Christmas tree

The invention discloses an automatic shearing machine for pine branches of a plastic Christmas tree. The automatic shearing machine comprises a rack, a feeding mechanism, a material pulling mechanism, a material cutting mechanism and a control circuit, wherein the feeding mechanism, the material pulling mechanism and the material cutting mechanism are arranged on the rack; the material cutting mechanism comprises a movable knife and a fixed knife; the feeding mechanism is arranged behind the material cutting mechanism along the longitudinal direction of the rack; the material pulling mechanism is arranged in front of the material cutting mechanism; the feeding mechanism presses the pine branches to feed forwards; after stems of front-end pine branches penetrate through a gap between the movable knife and the fixed knife, a chuck of the material pulling mechanism clamps the stems of front-end pine branches and pulls the pine branches to move forwards; when a detection device of the control circuit detects that heads of the front-end pine branches support against blade parts of the movable knife and the fixed knife, the pine branches are cut off by the material cutting mechanism. According to the automatic shearing machine disclosed by the invention, automatic shearing of the pine branches can be realized, and high shearing efficiency is realized; the shearing is performed according to the detected position of the heads of the pine branches, so that the shearing quality is high, and the requirements of large-batch and automatic production of the pine branches can be met.

Owner:SHENZHEN UNIV

Energy-saving type aluminum concentrated dissolving crucible furnace for pressure casting

InactiveCN108680013AImprove coherenceExtended stayCharge treatment typeCrucible furnacesCalcium silicateBrick

The invention discloses an energy-saving type aluminum concentrated dissolving crucible furnace for pressure casting. The energy-saving type aluminum concentrated dissolving crucible furnace comprisesa rotary chassis and a plurality of boiler devices arranged on the top of the rotary chassis, each boiler device comprises a heat preservation boiler body and a heat exchanger arranged at the top ofthe heat preservation boiler body, each heat preservation boiler body comprises a boiler body shell, a calcium silicate board, a nanometer board, mullite bricks and a pouring inner layer which are sequentially arranged from outside to inside, and the outer wall of each heat preservation boiler body is provided with a nozzle and an air blower. The rotary chassis is controlled to work to drive the different boiler devices to feed materials in turns, the production technology can have the good consistency, the production efficiency is greatly improved, and the automatic production requirement ismet; a thread fire guide groove is formed in the inner wall of the pouring inner layer, flames can burn layer by layer upwards, the staying time of the flames in hearths is prolonged, and the longer the staying time in the hearths is, the longer the heating time is; and waste gas water heat utilization can be achieved, and the energy saving aim is achieved.

Owner:佛山市西瓦克工业炉有限公司

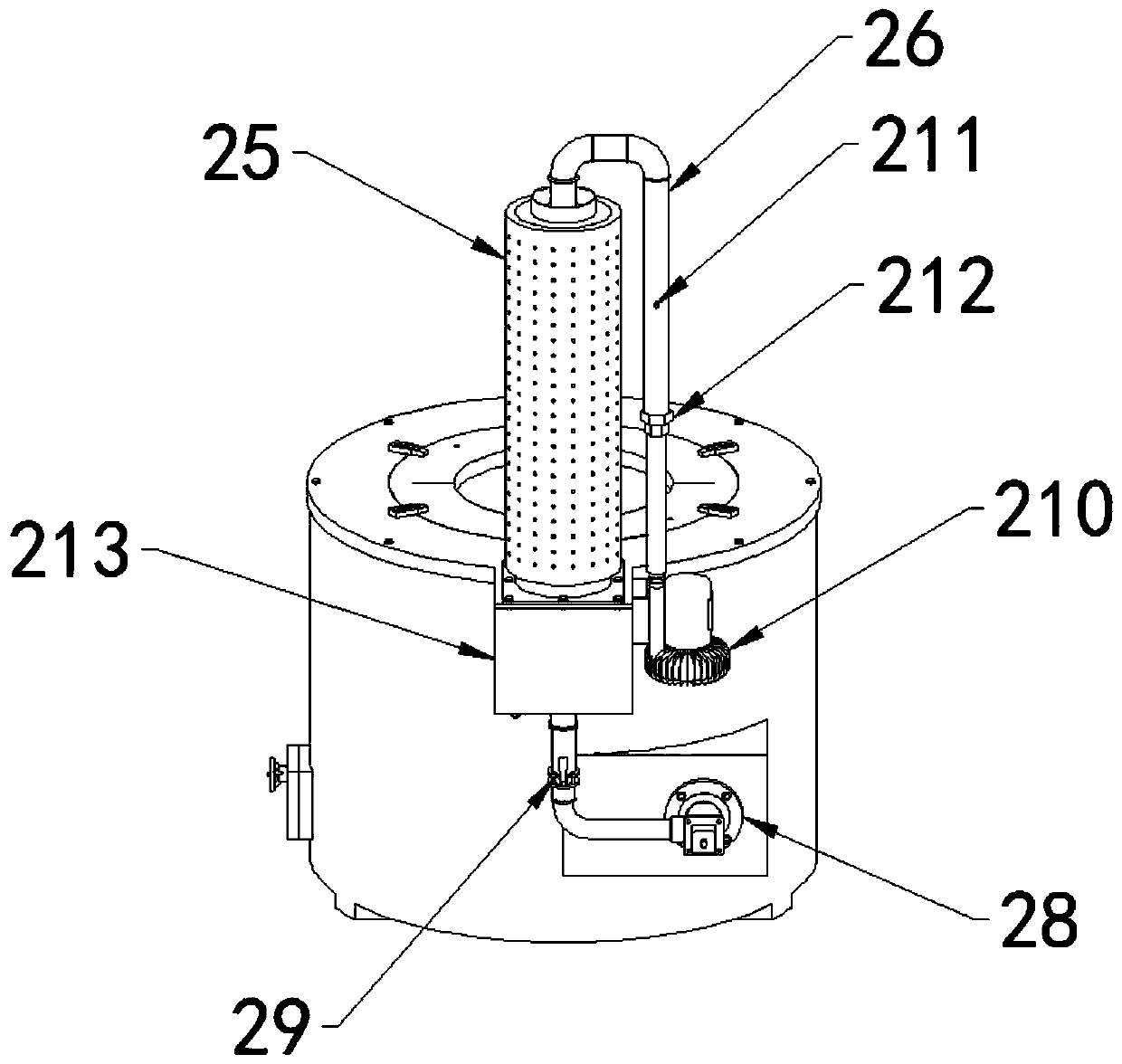

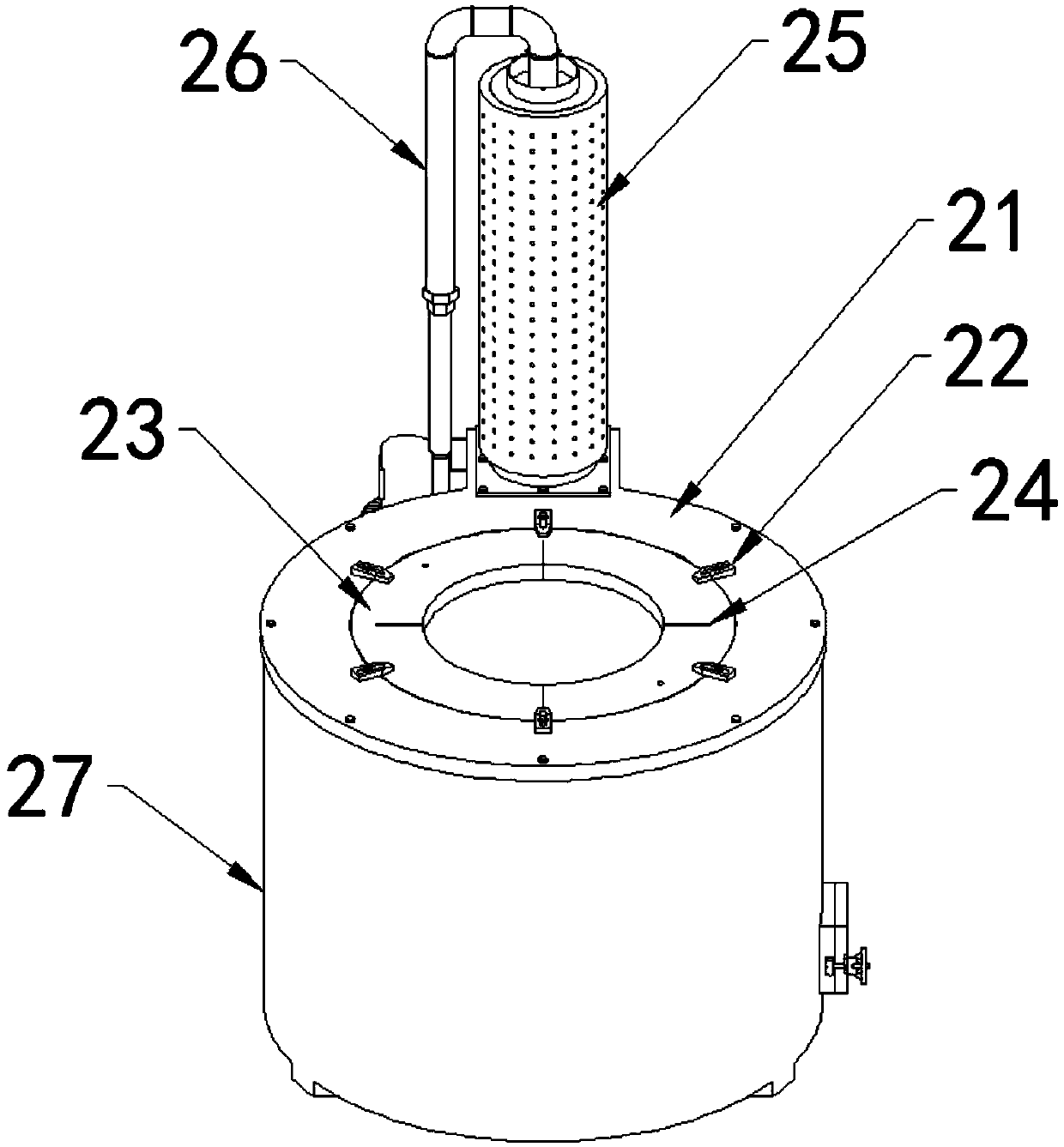

Full-automatic helium leakage detection device for fuel rods

ActiveCN106601315AAutomate operationResolve detectionNuclear energy generationNuclear monitoringProduction lineEconomic benefits

The invention relates to a full-automatic helium leakage detection device for fuel rods. The device comprises a feeding device, a conveying trolley, a leak detection container and a discharging device. The conveying trolley is arranged on the opening side of the leak detection container and used for conveying fuel rods to be detected to the leak detection container; the feeding device is arranged on one side of the conveying trolley and used for receiving the fuel rods from the previous working procedure and conveying the fuel rods to the conveying trolley; the discharging device is arranged on the other side of the conveying trolley and used for disassembling the detected fuel rods from the conveying trolley and conveying the detected fuel rods to the next working procedure. According to the leak detection device, the sealing performance of the fuel rods can be detected in batches in a nuclear fuel component production line, the helium leak detection working procedure is connected with previous and later working procedures on a production line, automatic operation of the whole process of feeding, leak detection and discharging of the helium leak detection device is achieved, the problems of artificial offline detection, low production efficiency and the like existing in the existing helium leak detection process are effectively solved, the production efficiency and economic benefits are improved, and the device is simple in structure, safe and reliable.

Owner:CHINA NUCLEAR POWER ENG CO LTD

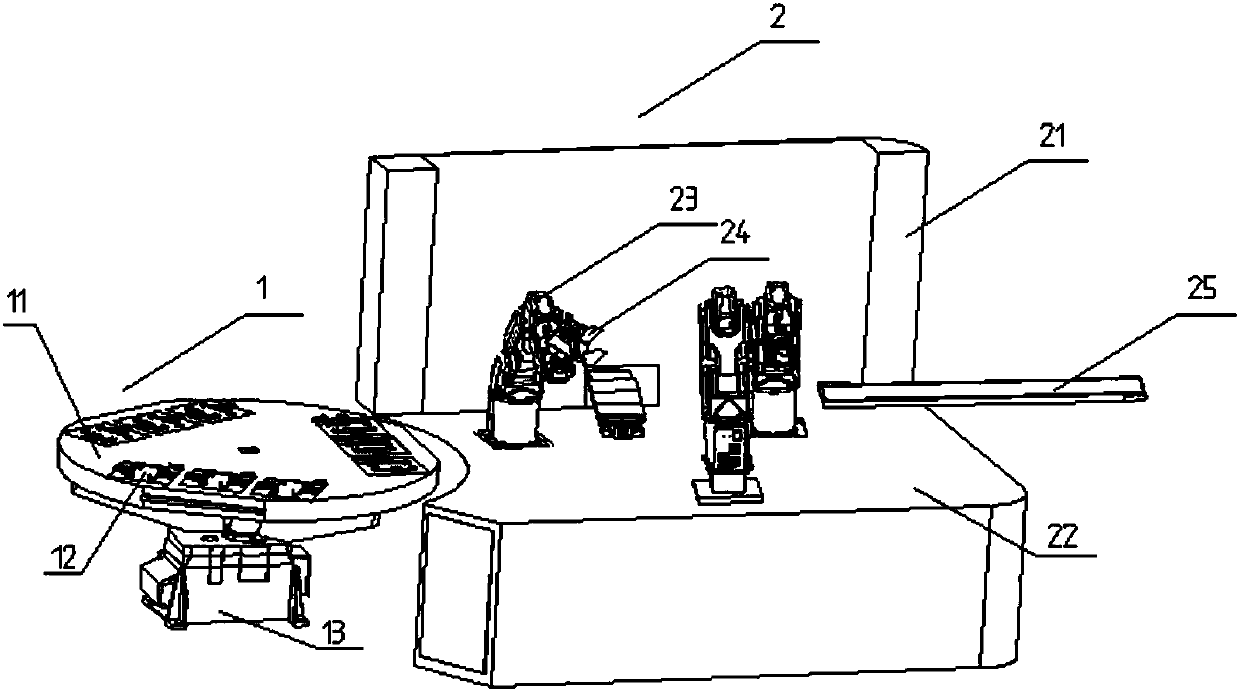

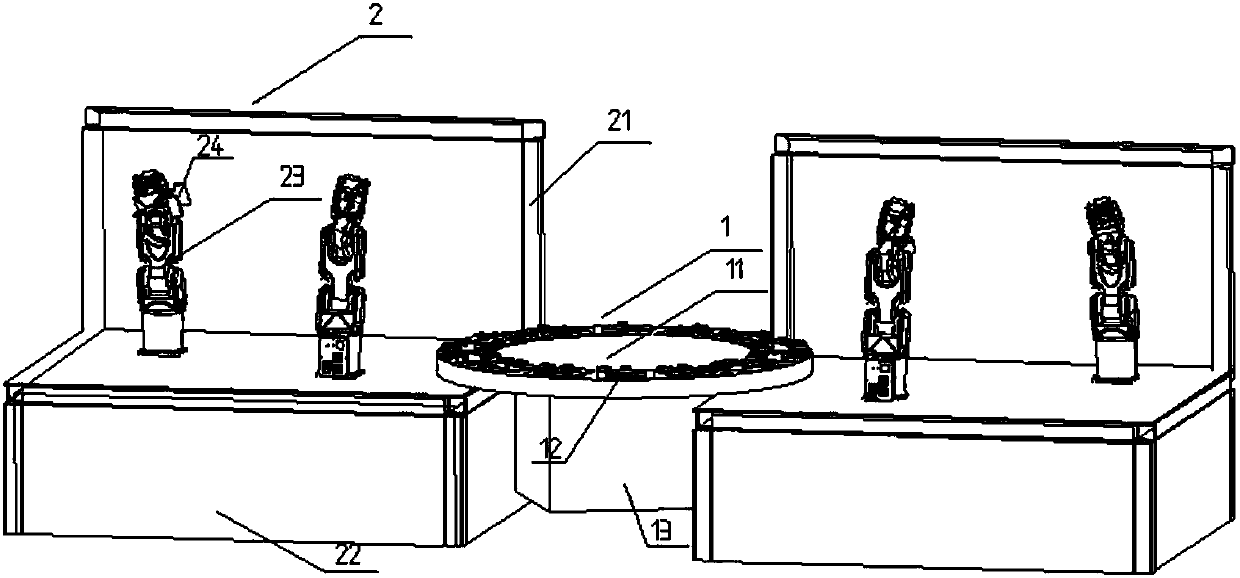

Robotic flexible production workstation

PendingCN108032089AImprove singlenessStrong specificityOther manufacturing equipments/toolsControl systemWorking environment

The invention belongs to the technical field of industrial automation and discloses a robotic flexible production workstation, comprising a material buffer device, a multifunctional work chamber and acontrol system. The material buffer device is connected with the multifunctional work chamber through a conveyer. The material buffer device comprises a rotary workbench, a plurality of positioning fixtures and a driving device; the driving device is connected with the rotary workbench; the positioning fixtures are fixed on the rotary workbench; the multifunctional work chamber comprises an operating platform, a material processing device and a material discharge passage; the control system controls the working state of the workstation. The robotic flexible production workstation has the advantages that the monotony and specificity of a traditional workstation are improved; the automatic production requirements on multiple stations and multiple material varieties can be met by making useof robotic flexibility; the robotic flexible production workstation is widely applicable, allows rapid switching of various materials within a short time and also allows rhythm uniformity for different procedures, so that production quality and working efficiency are improved, labor intensity is reduced and working environment is improved.

Owner:江苏海德工业机器人有限公司

Terminal wiring machine with terminal type convenient to exchange rapidly

PendingCN109533923APrevent movementMeet production requirementsConveyor partsEngineeringMechanical engineering

The invention discloses a terminal wiring machine with a terminal type convenient to exchange rapidly. The machine comprises a cabinet, a first sliding rail, a plurality of groups of feeding stations,a plurality of groups of second sliding rails and a fixing mechanism, wherein the first sliding rail is located at the feeding end of the cabinet, the feeding stations correspond to the second sliding rails, the feeding stations are arranged in the second sliding rails in a sliding mode, one ends of the second sliding rails correspond to one end of the first sliding rail, the second sliding railsare arranged on the fixing mechanism in a sliding mode, and the feeding stations can slide into the first sliding rail from one ends of the second sliding rails when the machine is used. According tothe machine, when a wiring terminal needs to exchange the terminal type, the corresponding feeding station is replaced, so that the corresponding feeding station slides to the feeding end of the terminal wiring machine, therefore the wiring terminals with different terminal types are obtained, the requirement for quickly exchanging the terminal type is met, the wiring efficiency is high, the wiring precision is high, and the wiring effect is good.

Owner:HUIZHOU ZHUCHENG WIRING SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com