Blank automatic loading and unloading travelling bogie

A technology of automatic loading and unloading and transporting trolleys, which is applied in the direction of transporting passenger cars, transporting and packaging, railway car body parts, etc., and can solve problems such as low degree of automation and scratches on the surface of steel pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

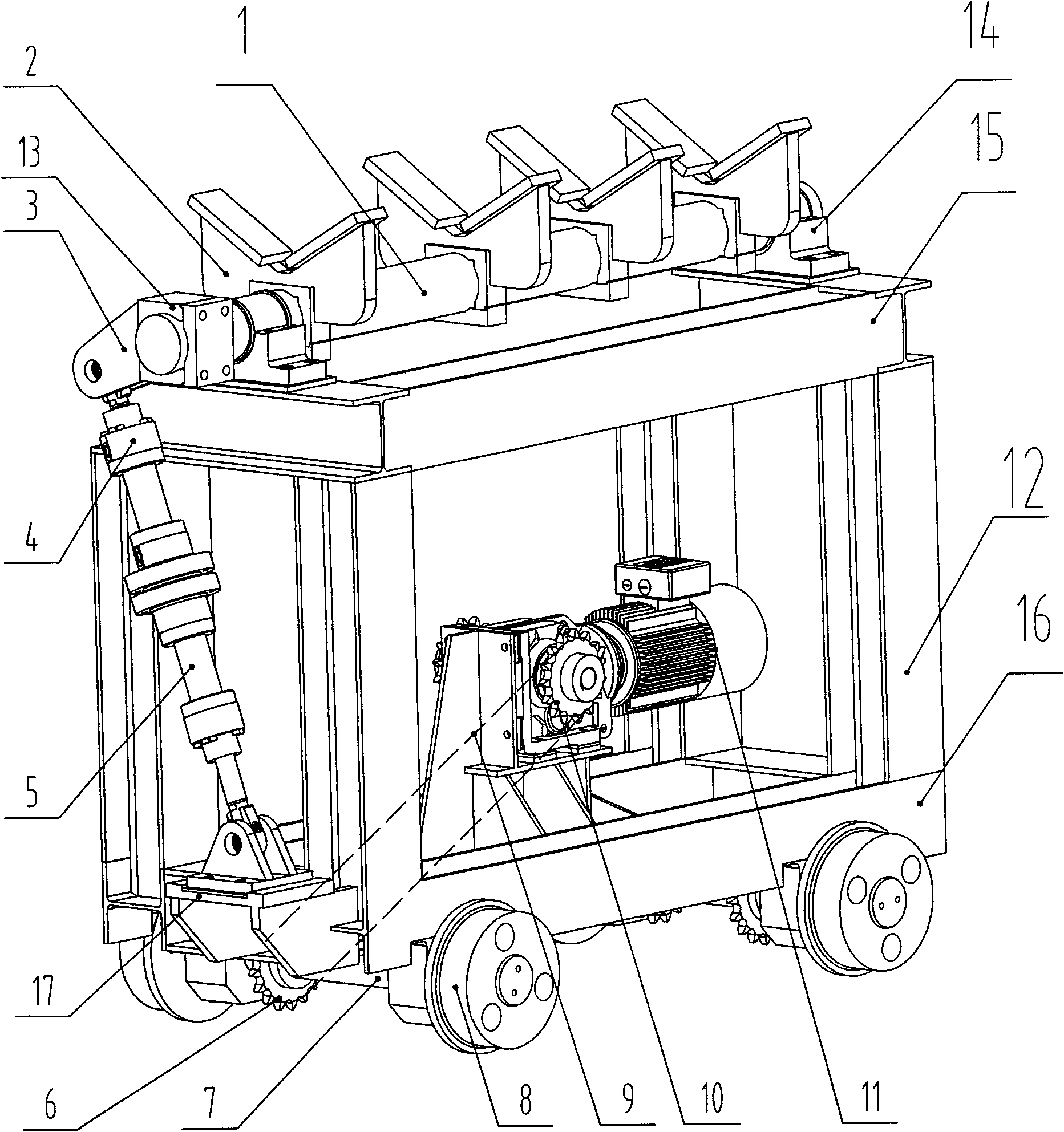

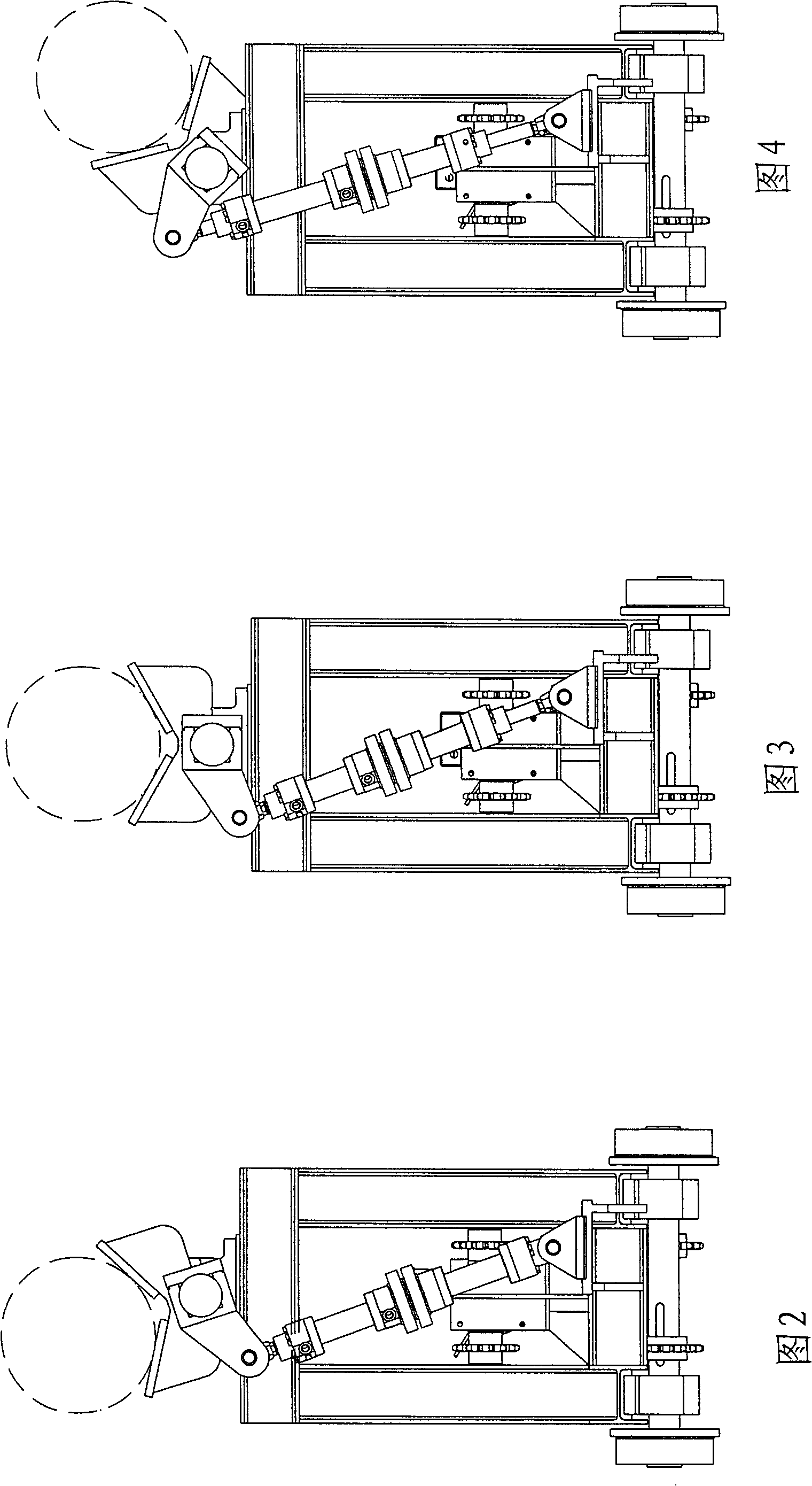

[0012] The blank automatic loading and unloading transportation trolley includes a car body 12, a wheel axle 7 and a wheel 8. The car body 12 is in the shape of a mouth. The lower bracket 16 of the car body 12 is provided with a motor and a reducer 11, and a motor and a reducer 11 The output shaft is provided with a driving sprocket 10, a passive sprocket 6 is fixedly provided on the wheel shaft 7, a chain 9 is provided between the driving sprocket 10 and the passive sprocket 6, and the driving sprocket 10 passes through the chain 9 drives the driven sprocket 6 and the wheel shaft 7 to rotate, thereby realizing the trolley to walk on the rail; at the end of the lower bracket 16 of the car body 12, a hydraulic cylinder bracket 17 is fixedly arranged, and a series connection is arranged on the hydraulic cylinder bracket 17 The hydraulic cylinders 4 and 5 of the vehicle body 12 are respectively provided with a front bearing seat 13 and a rear bearing seat 14 at both ends of the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com