Robotic flexible production workstation

A robot and flexible technology, applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc., can solve the problems of difficulty in automation, inconsistent beats, singleness and strong specificity, etc., to achieve beat consistency, improve production quality and Work efficiency, improve the effect of singleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

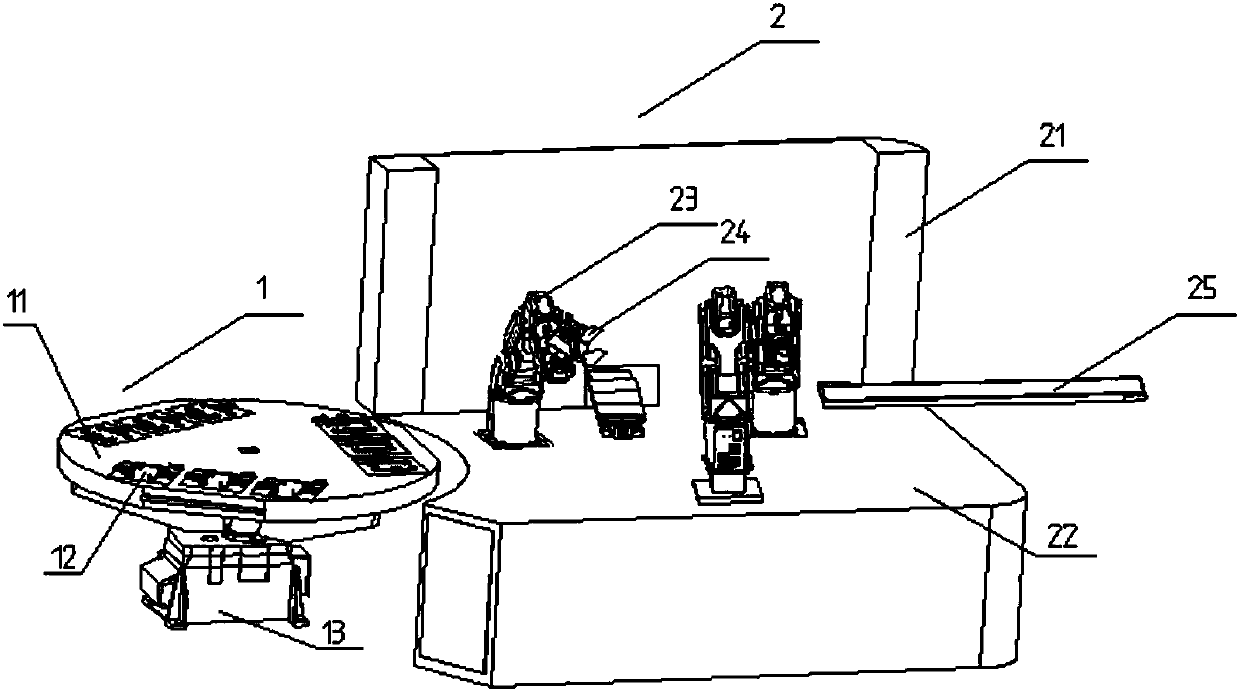

[0035] Take workpiece detection and labeling as an example:

[0036] like figure 1 As shown, firstly, the material is placed on the positioning fixture 12 manually or by a robot, and the number of positioning fixtures 12 is adjusted according to the beat of the workpiece detection process and the labeling process. This embodiment is equipped with detection equipment, and the positioner 13 drives the rotary table 11 Rotate the workpiece to the detection position, the detection equipment automatically detects the workpiece, uploads the detected data to the system, and finally rotates the worktable 11 to transfer the detected workpiece to the entrance of the multifunctional workshop 2. The material processing device in this embodiment is coordinated by a grabbing robot, a labeling robot and a sorting robot. The grabbing robot in the multifunctional workshop 2 grabs the detected workpieces according to the feedback signal, and places the unqualified workpieces in the designated a...

Embodiment 2

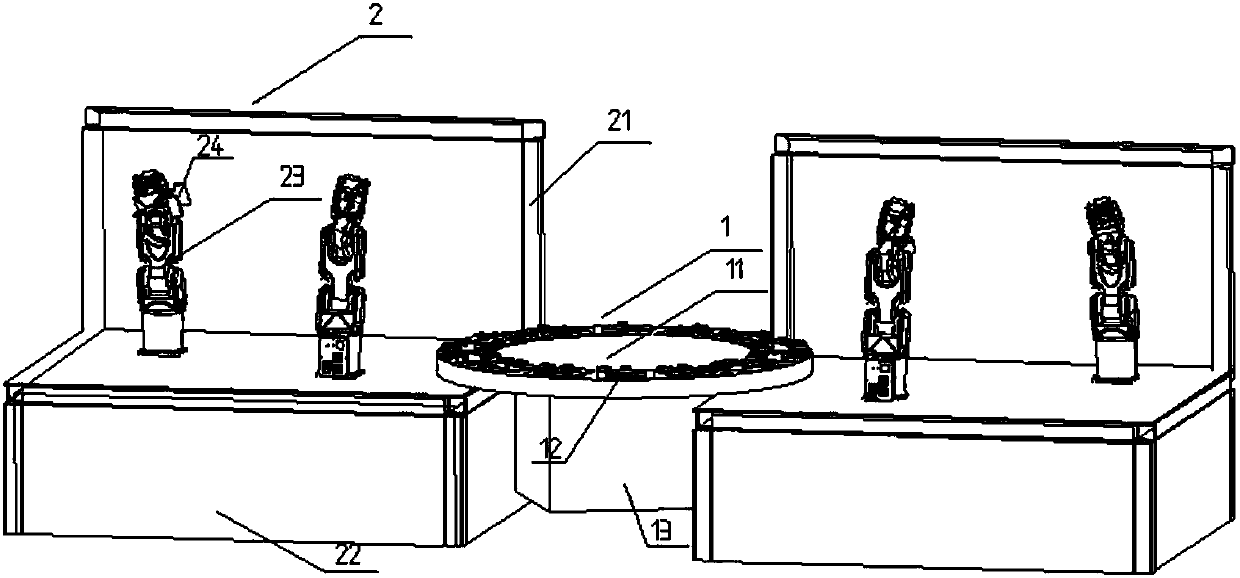

[0038] Take workpiece dispensing, curing, and assembly as examples:

[0039] like figure 2As shown, there are two multifunctional workshops in this embodiment, and the material processing device is coordinated by a grasping robot, a glue dispensing robot, an assembly robot and a sorting robot. First, the grasping robot in the first multi-functional workshop grabs the workpiece to the vicinity of the dispensing robot. The grasping robot and the dispensing robot cooperate with each other through specific programming control to quickly complete the dispensing of the workpiece. After the workpiece dispensing is completed, the workpiece is placed on the positioning fixture 12. In this embodiment, the material buffer device 1 is equipped with a curing device, and the workpiece is placed on the positioning fixture 12 for curing. According to the rhythm of the workpiece dispensing process, curing process, and assembly process The number of positioning jigs 12 is adjusted. After the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com