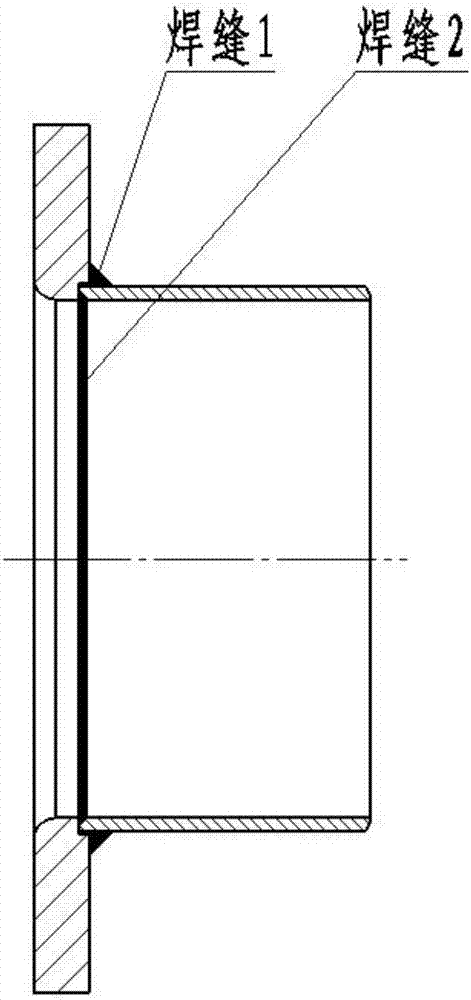

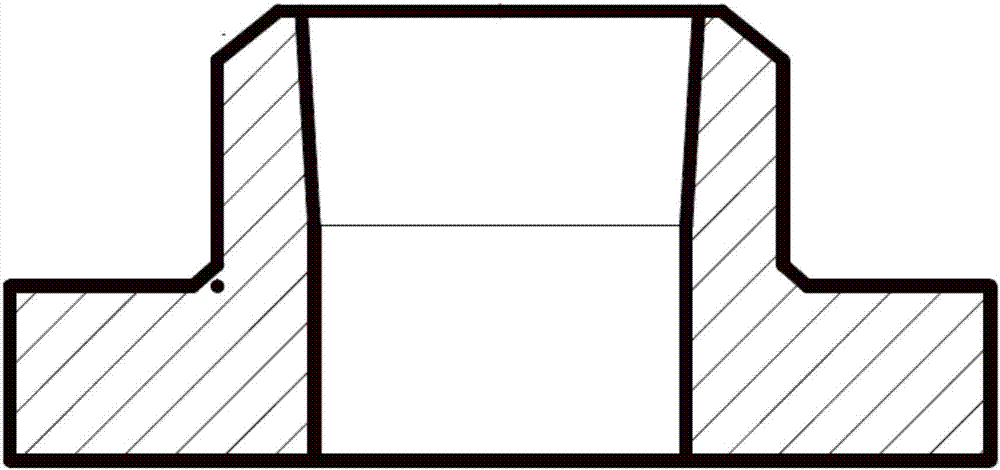

Weld neck flange machining technique

A technology of high neck flange and processing technology, which is applied in the direction of flange connection, pipe/pipe joint/pipe fitting, passing components, etc., which can solve the problems affecting the progress and development of product manufacturers, affecting the forming accuracy and consistency of products, and affecting the quality of products. Service life and other issues, to achieve the effect of easy control of neck forming quality, saving weld inspection costs and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A high neck flange processing technology, the processing technology includes the following processing steps;

[0035] The first step: choose 8053 aluminum as raw material;

[0036] The second step: according to the specifications of the high-neck flange, select the specifications of the aluminum alloy cast rod, and ensure that the height-to-diameter ratio of the billet after blanking is ≤2.5;

[0037] Step 3: Aluminum alloy cast rods are turned and skinned to ensure that defects such as oxidation passivation layer, casting inclusions, subcutaneous air bubbles and other defects on the surface are removed.

[0038] The fourth step: forging the billet, put the peeled billet into the electric furnace for heating, and then forge to obtain the forged billet;

[0039] Step 5: Reaming, ring rolling the billet on a ring rolling mill to obtain a semi-finished product, wherein: the outer diameter of the neck and the outer diameter of the bottom of the semi-finished product reach ...

Embodiment 2

[0054] A high neck flange processing technology, the processing technology includes the following processing steps;

[0055] The first step: choose 8053 aluminum as raw material;

[0056] The second step: according to the specifications of the high-neck flange, select the specifications of the aluminum alloy cast rod, and ensure that the height-to-diameter ratio of the billet after blanking is ≤2.5;

[0057] Step 3: Aluminum alloy cast rods are turned and skinned to ensure that defects such as oxidation passivation layer, casting inclusions, subcutaneous air bubbles and other defects on the surface are removed.

[0058] The fourth step: forging the billet, put the peeled billet into the electric furnace for heating, and then forge to obtain the forged billet;

[0059] Step 5: Reaming, ring rolling the billet on a ring rolling mill to obtain a semi-finished product, wherein: the outer diameter of the neck and the outer diameter of the bottom of the semi-finished product reach ...

Embodiment 3

[0074] A high neck flange processing technology, the processing technology includes the following processing steps;

[0075] The first step: choose 8053 aluminum as raw material;

[0076] The second step: according to the specifications of the high-neck flange, select the specifications of the aluminum alloy cast rod, and ensure that the height-to-diameter ratio of the billet after blanking is ≤2.5;

[0077] Step 3: Aluminum alloy cast rods are turned and skinned to ensure that defects such as oxidation passivation layer, casting inclusions, subcutaneous air bubbles and other defects on the surface are removed.

[0078] The fourth step: forging the billet, put the peeled billet into the electric furnace for heating, and then forge to obtain the forged billet;

[0079] Step 5: Reaming, ring rolling the billet on a ring rolling mill to obtain a semi-finished product, wherein: the outer diameter of the neck and the outer diameter of the bottom of the semi-finished product reach ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com