Terminal wiring machine with terminal type convenient to exchange rapidly

A terminal wiring and terminal technology, which is applied in the field of terminal wiring machines for quick replacement of terminal types, can solve the problems of large-scale batch production, high labor cost, and long wiring time, etc. High wiring efficiency and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

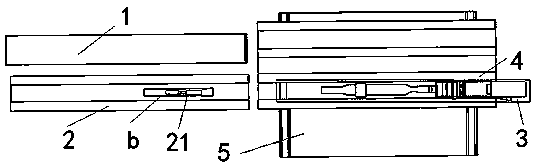

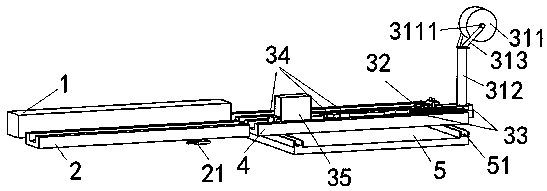

[0027] combined reference figure 1 , a terminal wiring machine of quick-change terminal type, including a cabinet 1, a first slide rail 2, two sets of loading stations 3 (one set of loading stations figure 1 not shown), two sets of second slide rails 4 and fixing mechanisms 5, wherein the first slide rails 2 are located at the feeding end of the cabinet 1, each of the feeding stations 3 and each of the second slide rails 4 Correspondingly, the feeding station 3 is slidably arranged in the second slide rail 4, one end of the second slide rail 4 corresponds to one end of the first slide rail 2, and the second slide rail 4 is slidably arranged on the On the fixing mechanism 5 , specifically, the fixing mechanism 5 is provided with a chute 51 , and a sliding seat is provided under the second slide rail 4 , and the sliding seat can slide in the chute 51 .

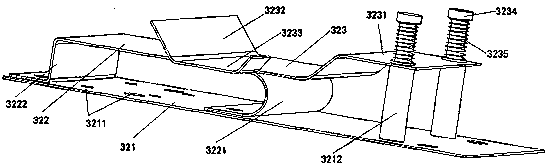

[0028] Wherein, the feeding station 3 includes a terminal feeding mechanism 31, a terminal feeding sensing mechanism 32, a su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com