A brick unloading and palletizing unit for sintered bricks and a brick unloading and palletizing method

A technology for sintering bricks and unloading bricks, which is applied in the direction of destacking of objects, stacking of objects, conveyor objects, etc., can solve the problems of harsh working environment, difficulty in unloading bricks by unloading bricks, and deformation of brick stacks. Achieve the effect of reducing labor intensity and production cost, improving production efficiency, and overcoming bonding problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

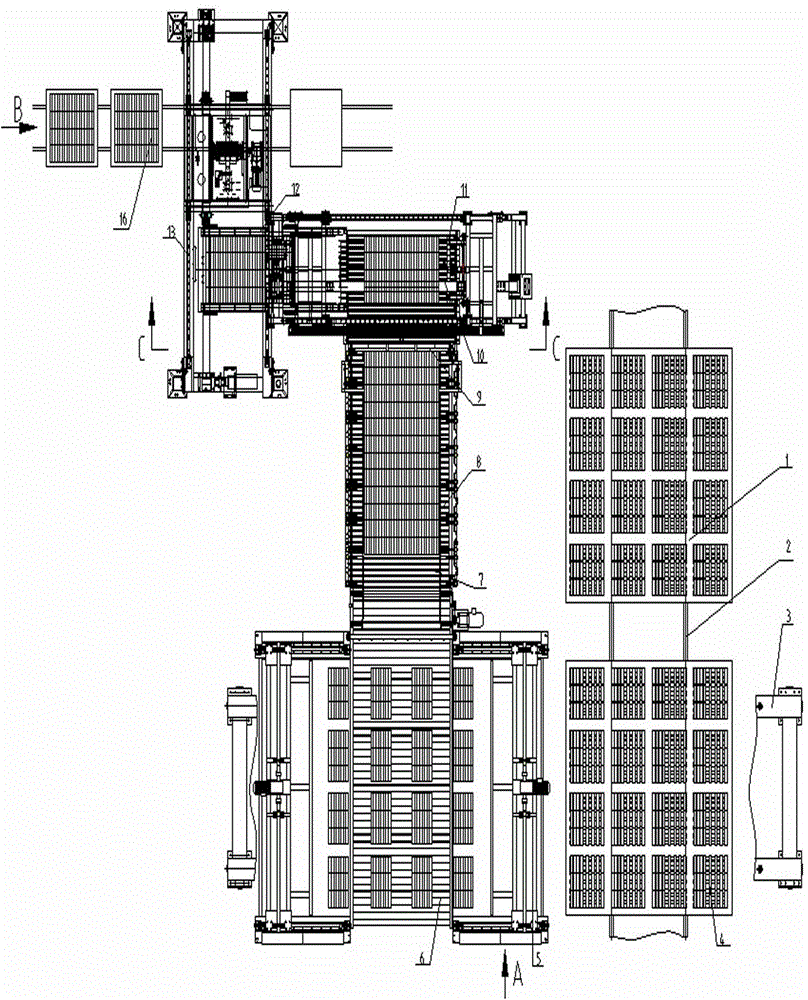

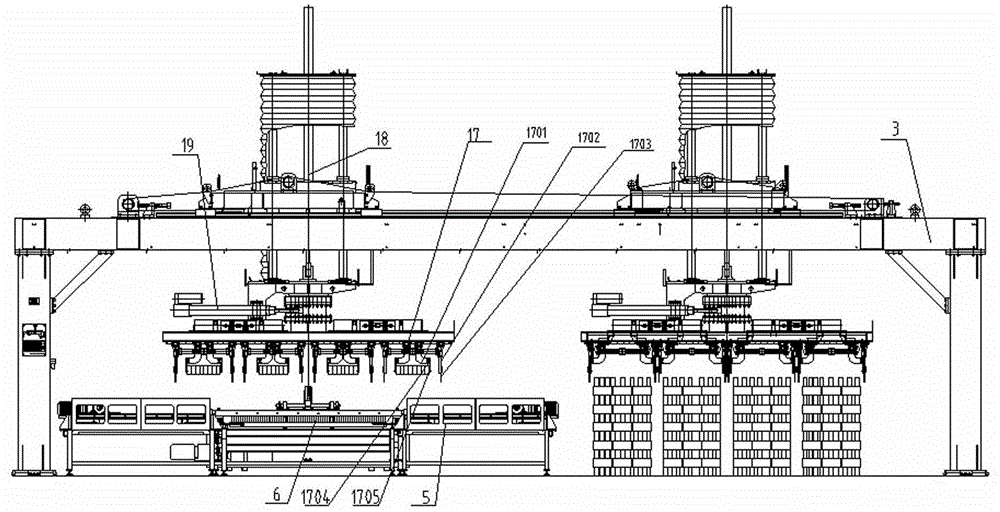

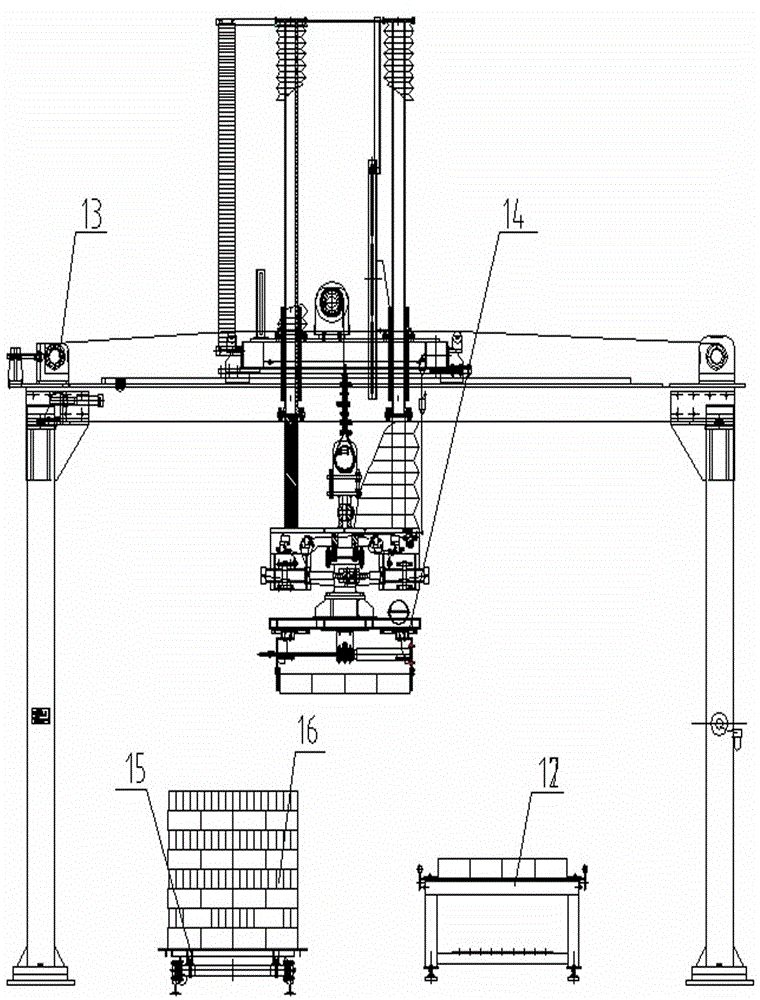

[0030] As shown in the figure, a brick unloading and stacking unit for sintered bricks is provided with a brick unloading machine 3 for unloading the sintered bricks 4 from the kiln car 1 to the brick unloading platform layer by layer and for unloading the bricks on the brick unloading platform. The pushing mechanism 5 for horizontal gathering is provided with a chain conveyor belt 6 in the middle of the brick unloading platform that can transfer the bricks gathered horizontally to the first roller conveying platform connected to it, and on the first roller conveying platform 7 There is a brick aligning device 8 which can realize the longitudinal collection of bricks, and a second roller conveying platform 10 connected to it is provided at the end of the first roller conveying platform 7, and the first roller conveying platform 7 is un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com