Carton centering mechanism of production line conveyor

A centering mechanism and conveyor technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of low production efficiency and operation quality, inability to realize automatic operation, and unfavorable production efficiency, so as to achieve good operation quality and improve the market Competitiveness and the effect of improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

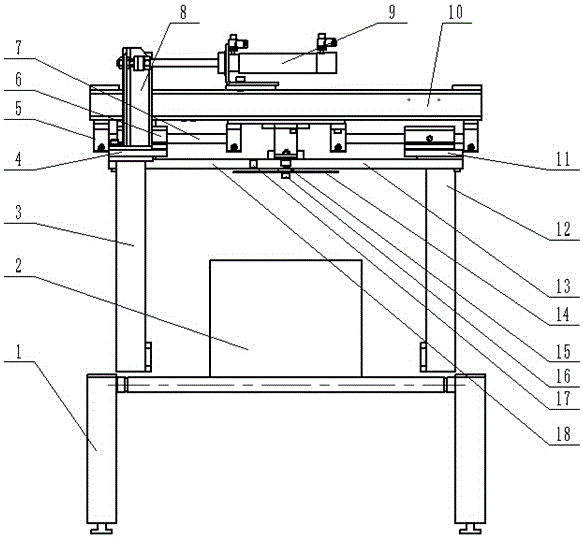

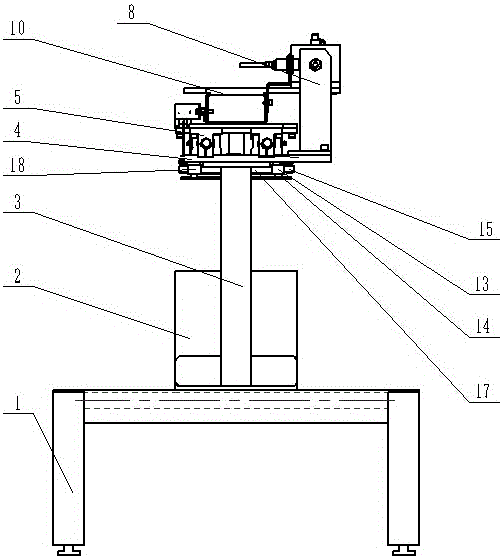

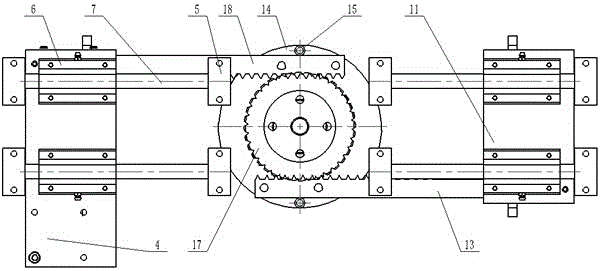

[0024] Embodiment 1: as Figure 1-5 As shown, a carton centering mechanism of a production line conveyor includes swing arm I3, mounting plate I4, support 5, sliding bearing 6, sliding shaft 7, vertical plate 8, two-way cylinder 9, top beam 10, mounting plate II11, Swing arm II12, rack I13, support plate 14, support plate fixed shaft 16, gear 17, rack II18;

[0025] The swing arm I3 is connected with the mounting plate I4 through bolt connection; one end of the mounting plate I4 is connected with the vertical plate 8 and the vertical plate 8 is installed vertically with the mounting plate I4; the cylinder rod of the two-way cylinder 9 is fixed by bolt connection In the upper end hole of the vertical plate 8; the cylinder liner of the two-way cylinder 9 is also fixed on the top beam 10 by bolt connection; the 8 bearings 5 are fixedly installed in a row of four by bolt connection, and two rows of one column correspond to each other. The installation position under the top bea...

Embodiment 2

[0030] Embodiment 2: as Figure 1-5 As shown, a carton centering mechanism of a production line conveyor includes a swing arm Ⅰ3, a mounting plate Ⅰ4, a support 5, a sliding bearing 6, a sliding shaft 7, a vertical plate 8, a two-way cylinder 9, a top beam 10, a mounting plate Ⅱ11, Swing arm II12, rack I13, support plate 14, support plate fixed shaft 16, gear 17, rack II18;

[0031]The swing arm I3 is connected with the mounting plate I4 through bolt connection; one end of the mounting plate I4 is connected with the vertical plate 8 and the vertical plate 8 is installed vertically with the mounting plate I4; the cylinder rod of the two-way cylinder 9 is fixed by bolt connection In the upper end hole of the vertical plate 8; the cylinder liner of the two-way cylinder 9 is also fixed on the top beam 10 by bolt connection; the 8 bearings 5 are fixedly installed in a row of four by bolt connection, and two rows of one column correspond to each other. The installation position u...

Embodiment 3

[0035] Embodiment 3: as Figure 1-5 As shown, a carton centering mechanism of a production line conveyor includes a swing arm Ⅰ3, a mounting plate Ⅰ4, a support 5, a sliding bearing 6, a sliding shaft 7, a vertical plate 8, a two-way cylinder 9, a top beam 10, a mounting plate Ⅱ11, Swing arm II12, rack I13, support plate 14, support plate fixed shaft 16, gear 17, rack II18;

[0036] The swing arm I3 is connected with the mounting plate I4 through bolt connection; one end of the mounting plate I4 is connected with the vertical plate 8 and the vertical plate 8 is installed vertically with the mounting plate I4; the cylinder rod of the two-way cylinder 9 is fixed by bolt connection In the upper end hole of the vertical plate 8; the cylinder liner of the two-way cylinder 9 is also fixed on the top beam 10 by bolt connection; the 8 bearings 5 are fixedly installed in a row of four by bolt connection, and two rows of one column correspond to each other. The installation position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com