Sintered brick unloading manipulator device

A technology of sintered bricks and manipulators, applied in the direction of conveyor objects, transportation and packaging, object stacking, etc., can solve problems such as brick stacks cannot be reliably clamped and unloaded bricks, achieve stable and reliable clamping, improve production efficiency, and expand The effect of versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

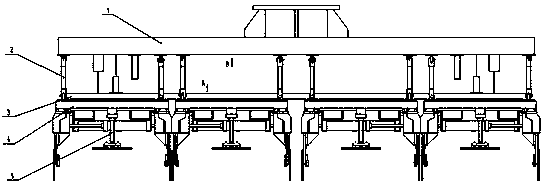

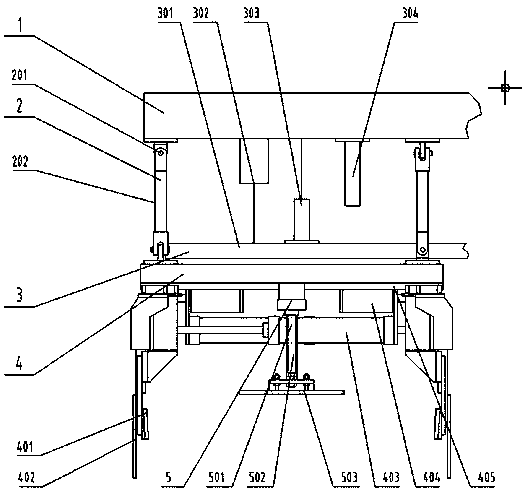

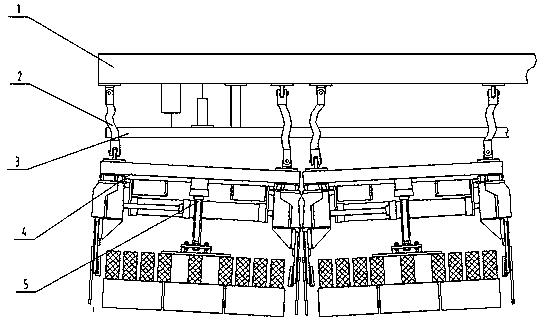

[0023] As shown in the figure, the specific implementation method is as follows:

[0024] A sintered brick unloading robot device, comprising a hanger 1 and a plurality of gripping units 4 installed at the bottom of the hanger, the top of the gripping unit 4 is provided with a connecting bracket, and the connecting brackets are all installed on the hanging bracket through a flexible device 2. On the bottom of the frame 1, a pressing device 3 is also provided between the hanger 1 and the clamp unit 4, and the pressing device 3 includes a pressing power 302, a guiding device 303, a pressing frame 301 and an upper limit Mechanism 304, the compression frame 301 is installed on the bottom of the hanger 1 through the compression power 302, the compression power 302 drives the compression frame 301 to reciprocate up and down, the upper limit mechanism 304 is arranged between the hanger 1 and the compression frame 301, the upper limit The position mechanism 304 is installed on the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com