Concrete block stacking machine

A technology of concrete blocks and palletizers, which is applied in the stacking of objects, unstacking of objects, transportation and packaging, etc. It can solve problems such as poor working environment, inability to proceed with mechanized and automated brick unloading, and unstable brick stacks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

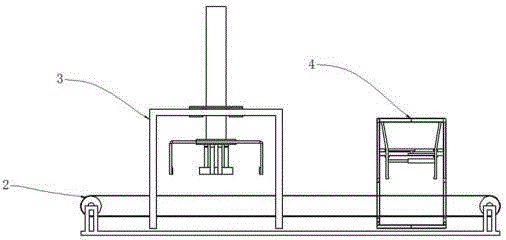

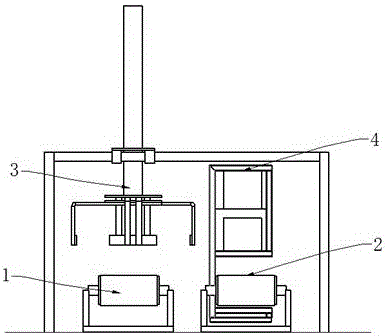

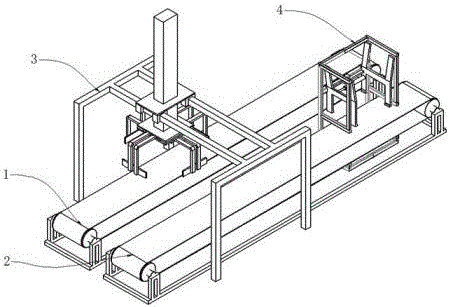

[0016] See Figure 1-5 , a concrete block palletizer, comprising: a feeding conveyor belt 1, a palletizing conveyor belt 2, a palletizer 3, and a pallet conveyor 4;

[0017] The feed conveyor belt 1 transports the formed concrete block products to the stacker;

[0018] The palletizing conveyor belt 2 is arranged on one side of the feed conveyor belt 1, and is arranged in parallel with the feed conveyor belt 1;

[0019] The palletizer 3 includes: a support frame 31, a guide rail 32, a lifting device 33, a transverse clamping frame 34, a longitudinal clamping frame 35, and a platform 36;

[0020] The support frame 31 is a door-shaped structure, and the support frame 31 is arranged above the feeding conveyor belt 1 and the stacking conveyor belt 2;

[0021] The guide rail 32 is arranged on the top of the support frame 31, and is vertically arranged with the feeding conveyor belt 1 and the stacking conveyor belt 2;

[0022] Described platform 36 is provided with slider, and sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com