Automatic welding device for automobile sealing pad

An automatic welding and gasket technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of stainless steel sheet grasping and adhesion, low single-machine operation efficiency, unstable product quality, etc., to achieve product quality assurance, good The effect of production efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

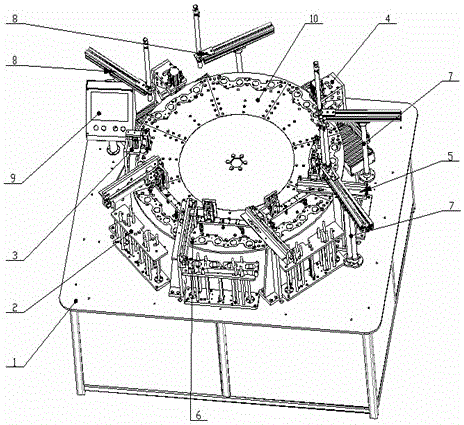

[0037] Example 1, see figure 1 , 2 . 5. Movable positioning pin device 6;

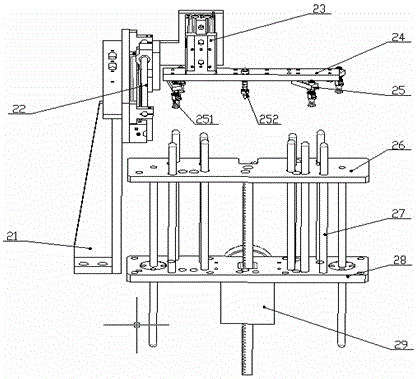

[0038] The feeding device 2 comprises a feeding bracket 21, a slide cylinder 22 is installed on the loading bracket 21, a lifting slide cylinder 23 is installed on the cylinder rod of the slide cylinder 22, and a vacuum suction cup fixing plate 24 is installed on the lifting slide cylinder 23, Vacuum suction cup combination 25 is installed on the vacuum suction cup fixed plate 24; Lifting platform 26 is installed below corresponding vacuum suction cup combination 25, and lifting platform 26 is connected with lifting motor through the rack of lifting motor combination 29, and lifting motor 29 and base fixing plate 28 pass bolts Connect together, fix the base fixing plate 28 on the body 1, and fix the material column 27 and the base fixing plate 28 together;

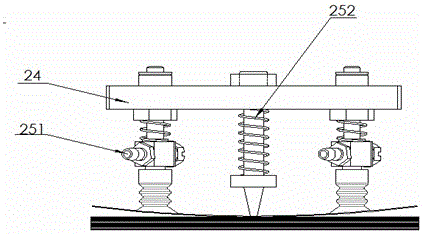

[0039] The vacuum chuck assembly 25 includes two vacuum chucks 251 and a separator 252, the separator 252 is located between the two vacuum chu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com