Chemical polishing agent

A chemical polishing and coupling agent technology, applied in the field of chemical polishing agents, can solve problems such as leaving gas marks, product abnormalities, corrosion, etc., and achieve the effect of reducing corrosion and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

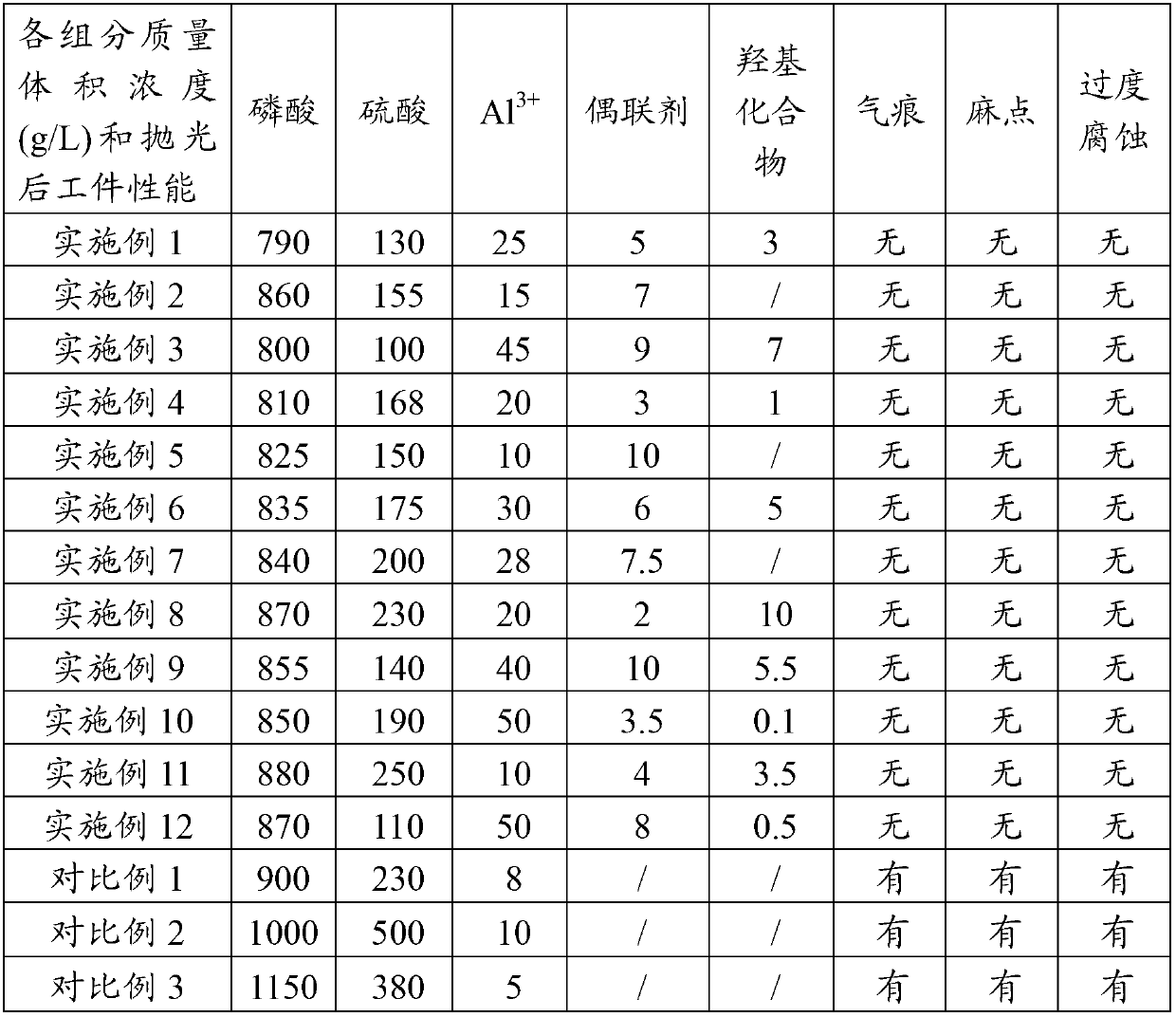

[0018] At normal temperature and pressure, weigh the components specified in Table 1 and add them to water, and stir until each component is completely dissolved, so that the mass volume concentration of each component of the chemical polishing agent is shown in Table 1.

[0019] In this example, Al 3+ It is obtained by dissolving aluminum oxide, aluminum phosphate, aluminum sulfate and aluminum hydroxide, the coupling agent is vinyl silane, and the hydroxyl compound is ethylene glycol.

[0020] Pour the prepared chemical polishing agent into the tank and heat it so that the temperature of the liquid in the tank is 80°C. Dip the clamped aluminum alloy workpiece into the tank, swing the workpiece at a frequency of 35 times per minute, and take out the workpiece after 100 seconds.

[0021] Observe with the naked eye whether there are gas marks and pitting above the opening of the chemically polished aluminum workpiece, and place the workpiece in the air for 30 seconds to observ...

Embodiment 2

[0023] The method of Example 1 was repeated for each component specified in Table 1, and the test results are listed in Table 1. In this example, Al 3+ It is obtained by dissolving alumina, and the coupling agent is aminosilane.

Embodiment 3

[0025] The method of Example 1 was repeated for each component specified in Table 1, and the test results are listed in Table 1. In this example, Al 3+ It is obtained by dissolving aluminum phosphate, the coupling agent is methacryloxysilane, and the hydroxyl compound is glycerol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com