Inner hole clamping device

A technology of clamping device and inner hole, which is applied in the field of quick pick-up device for parts and components, can solve the problems of unreliable clamping and picking of workpieces with small inner holes and inner holes, so as to ensure reliability, ensure high-precision clamping, and improve clamping reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

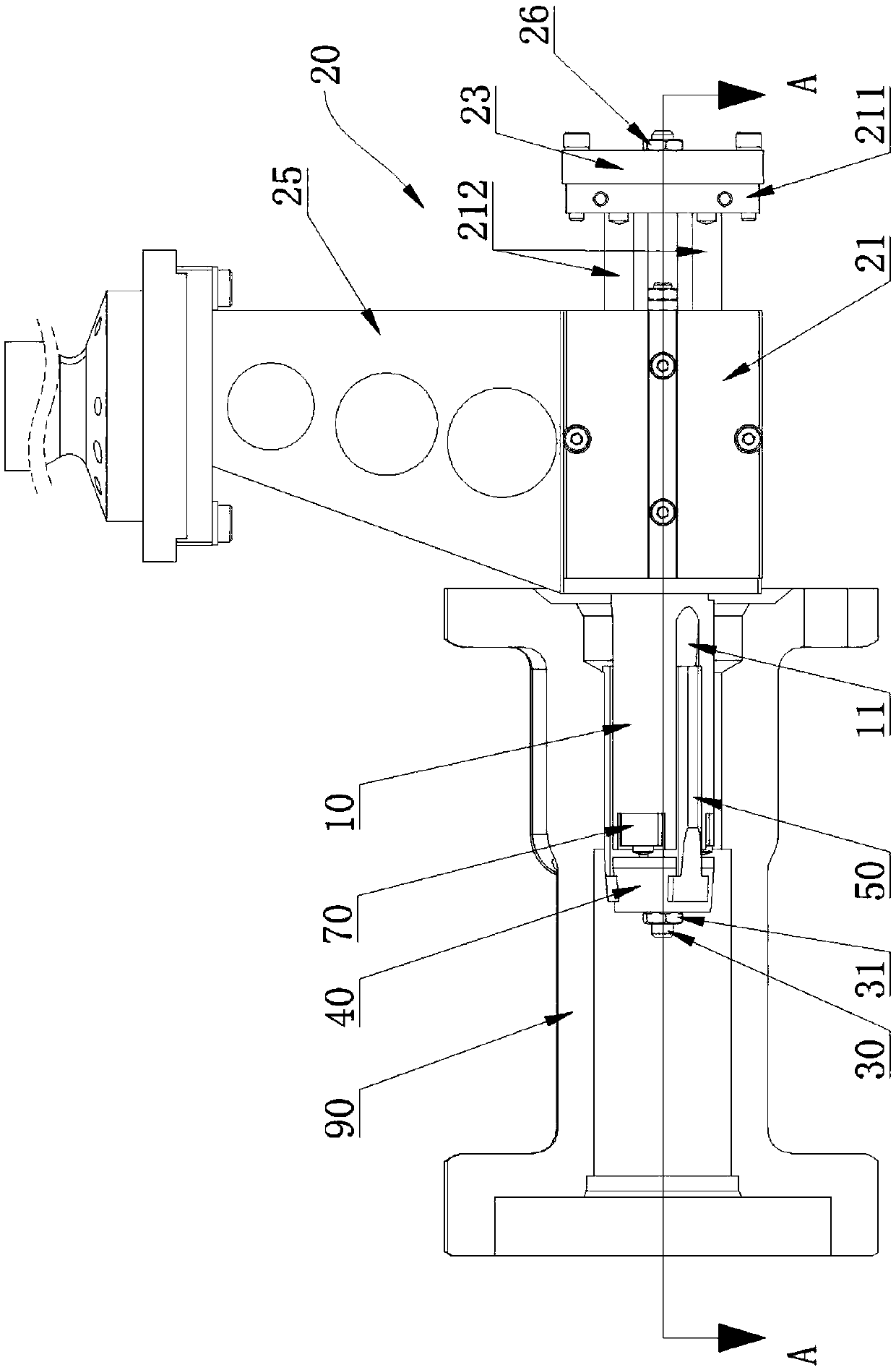

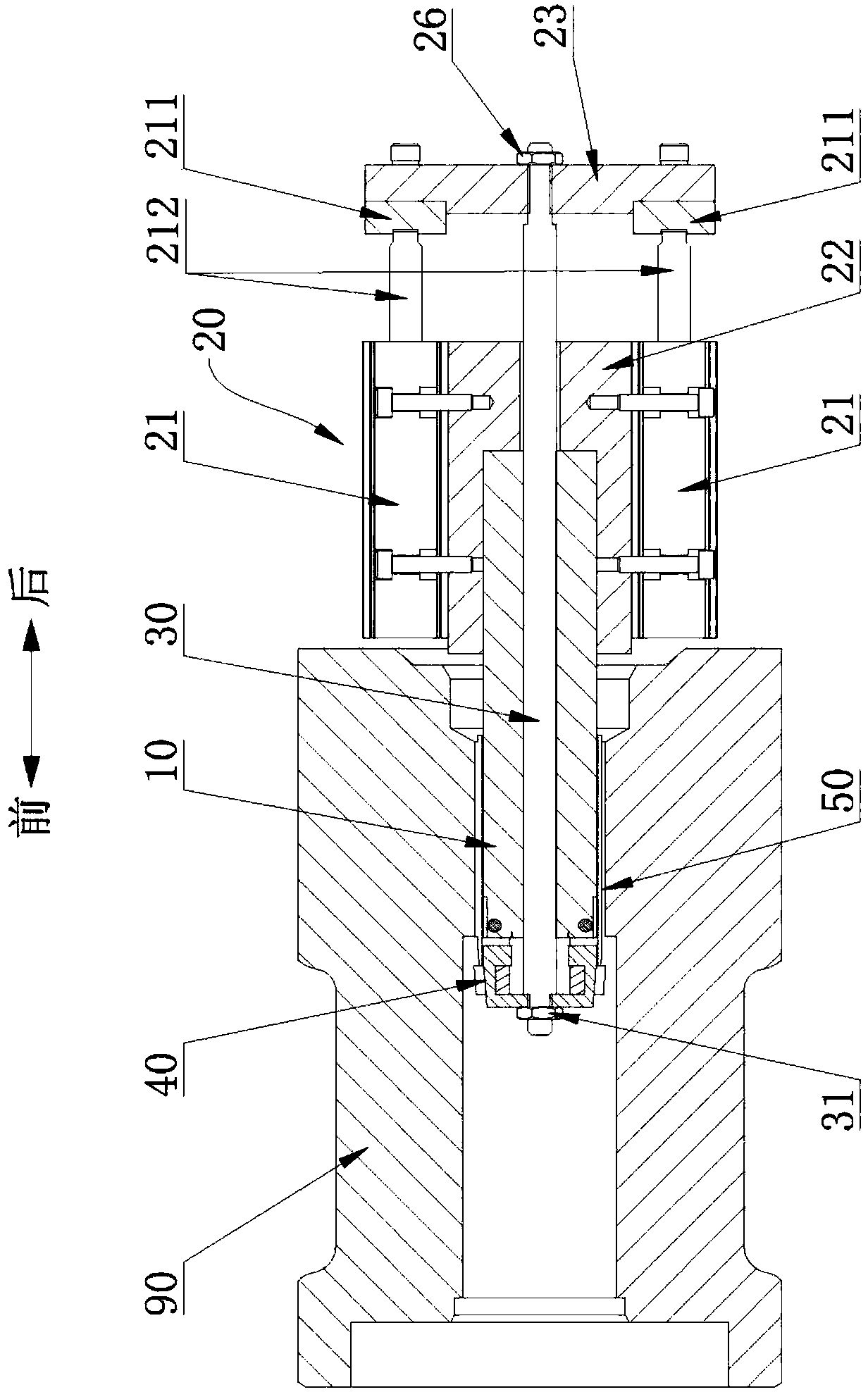

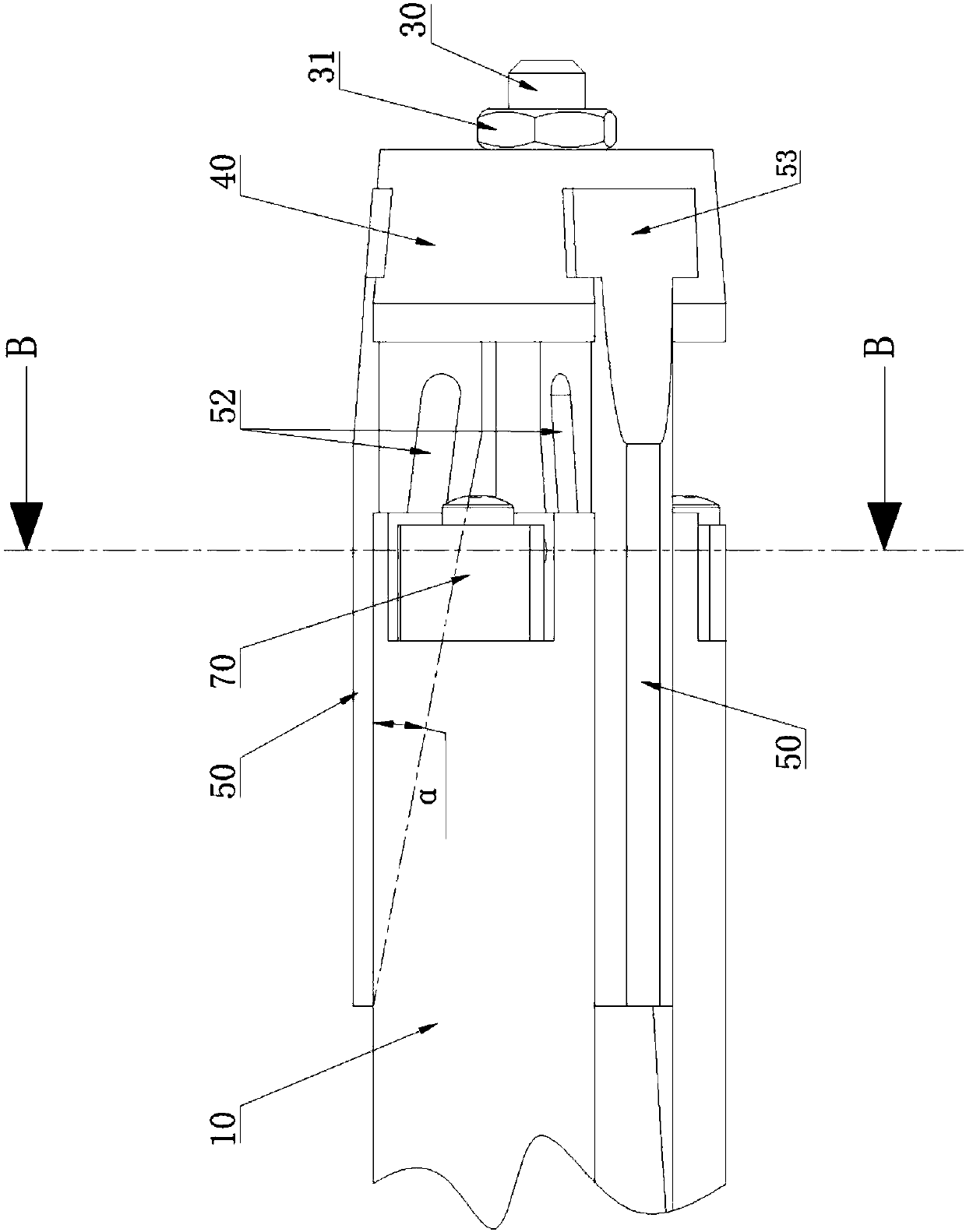

[0035] See Figure 1 to Figure 5 , the inner hole clamping device, which includes a mandrel 10 and a driving mechanism 20, the mandrel 10 is provided with an axial center through hole, and an axially movable pull rod 30 is provided through the axial center through hole, and the front end of the pull rod 30 is connected with The pulling block 40 and the rear end are connected to the driving mechanism 20. The outer peripheral surface of the front end of the mandrel 10 is evenly distributed along the circumferential direction with three slide grooves 11 extending horizontally in the axial direction and parallel to each other. The wedge-shaped groove surface 111 gradually increases forward, the angle α between the wedge-shaped groove surface 11 of the chute and the axial horizontal plane is 5°-20°, and a sliding claw 50 is respectively accommodated in the three chute grooves 11, and the sliding claw 50 is provided with The wedge-shaped inclined surface 51 that cooperates with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com