Primer for silane modified building sealant

A technology of silane modification and primer, applied in the field of materials, can solve the problems of poor compatibility, poor flexibility, poor water resistance and hydrolysis resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

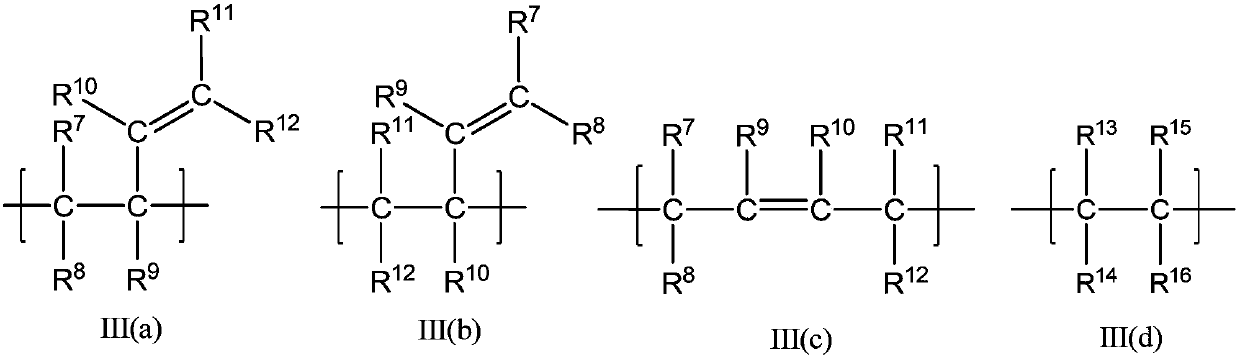

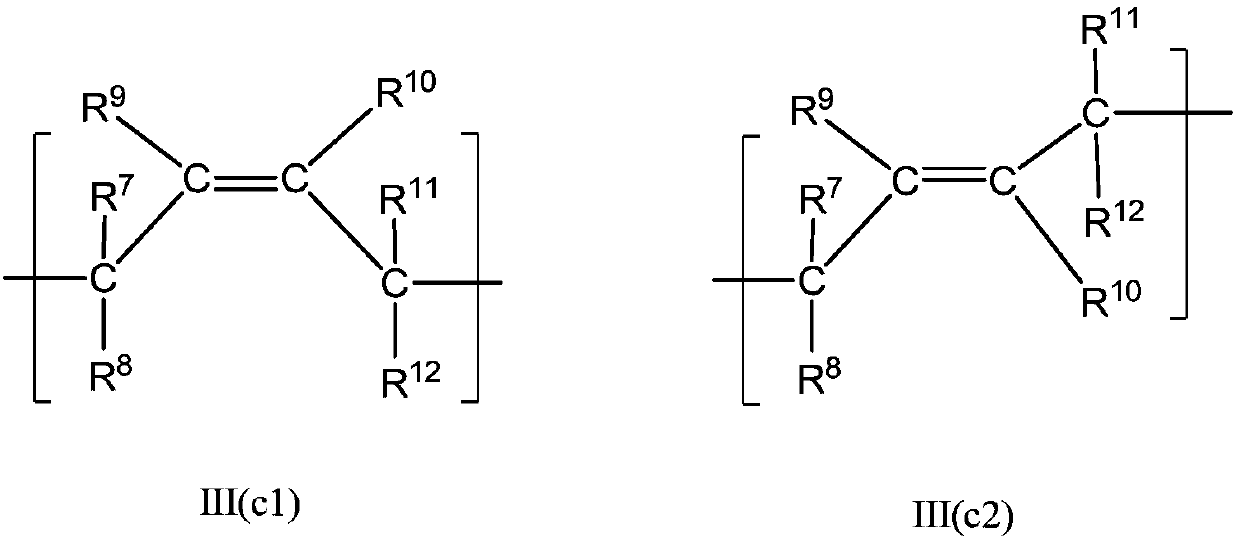

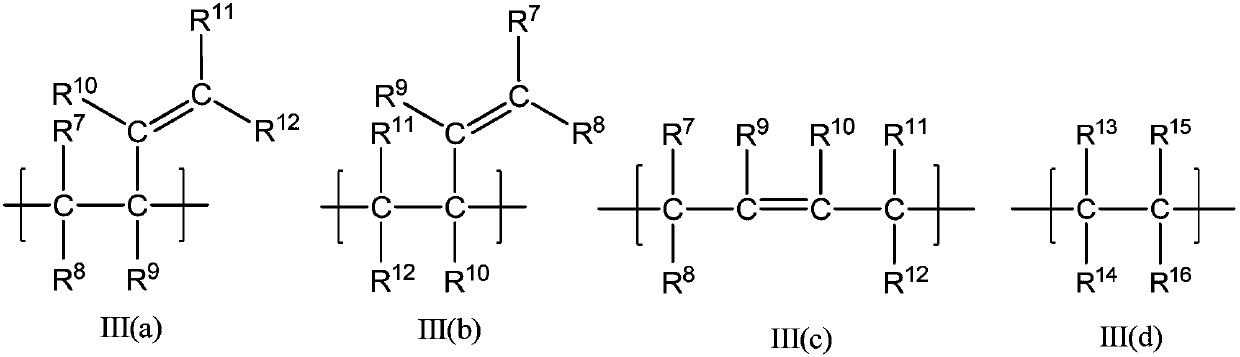

Method used

Image

Examples

Embodiment 1

[0135]

[0136]

[0137] Concrete selection and mass parts of each component in table 1 embodiment 1

[0138] In this embodiment 1, the γ-trimethoxysilane end-capped polybutadiene of silane-modified polymer (A) is the product of commercially available Evonik for selection EP ST-M, the specific structure and description are detailed in the specification part.

[0139] In this example, the crosslinking agent (B) is a methylphenyl silicone resin containing multiple methoxysilyl groups. It is prepared by referring to the methods of WO2008 / 107331, WO 2015 / 057851 and WO 2015 / 158624: Add 1400g of phenyltrimethoxysilane (or PTMO) and methyltrimethoxysilane (or MTMO) into a four-necked flask with a dropping funnel (connected to vacuum during distillation), reflux water condenser, stirrer and thermometer 600g (Ph / Me=1.6 / 1, mol / mol) was stirred and mixed, stirred at room temperature and mixed with 40g of 20% aqueous hydrochloric acid solution, heated to 65-68°C under condensation...

Embodiment 2

[0142]

[0143]

[0144] Concrete selection and mass parts of each component in table 2 embodiment 2

[0145] Same as in Example 1, silane-modified polymer (A) is silane-terminated polybutadiene EP ST-M, the crosslinking agent (B) is also the methylphenyl silicone resin with an average molar mass of 1100g / mol and a viscosity of 30cPs at 23°C prepared in Example 1; the silane-modified polymer (P) is selected STP-E 10, commercially available from Wacker Chemie, is α-dimethoxysilane-terminated polypropylene glycol, whose hydrolytic crosslinking does not require organometallic catalysts, and can promote the hydrolysis and crosslinking of other compounds containing trimethoxysilane structures. Linkage, its specific structure as described in the description; 1146 is a commercial product of EVONIK, which is an oligomer copolymerized with aminosilane and alkylsilane, and is used as the silane coupling agent (C) in this embodiment.

[0146] The specific preparation steps of ...

Embodiment 3

[0148]

[0149] Concrete selection and mass parts of each component in table 3 embodiment 3

[0150] In this embodiment 3, the silane-modified polymer (A) is a mixture of silane-modified polyisoprene and silane-modified polybutadiene of formula I, and the preparation method is: using hydroxyl-terminated isoprene ( 1, 2 addition structure is the main, molecular weight is 30000,) using hydroxyl-terminated polybutadiene R-15 (commercially purchased from CRAY VALLEY in the United States, obtained by free radical polymerization, number average molecular weight 2500 to 2800 mol / g, average functionality of hydroxyl group 2.2 to 2.6) was mixed at a mass ratio of 1:1 and heated to 110°C And vacuum stirring and dehydration for 2h, and cooling to room temperature, the mixture of the obtained hydroxyl-terminated polybutadiene and hydroxyl-terminated polyisoprene is used as a raw material, firstly mixed with TDI (toluene diisocyanate, commercially available Commercially available) was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com