Method and device for welding PTFE (Polytetrafluoroethylene) plates

A welding method and PTFE technology are applied in the field of PTFE plate welding and installation, which can solve the problems of unavailability and achieve the effect of smooth welding seam.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] 1. Selection of raw materials

[0030] PTFE plates made of PTFE M-111, PTFE TFM1700, PTFE TFM1705, and PTFE TFM1600 were selected, and welding tests were performed on PTFE plates of the same material.

[0031] 2. Welding device.

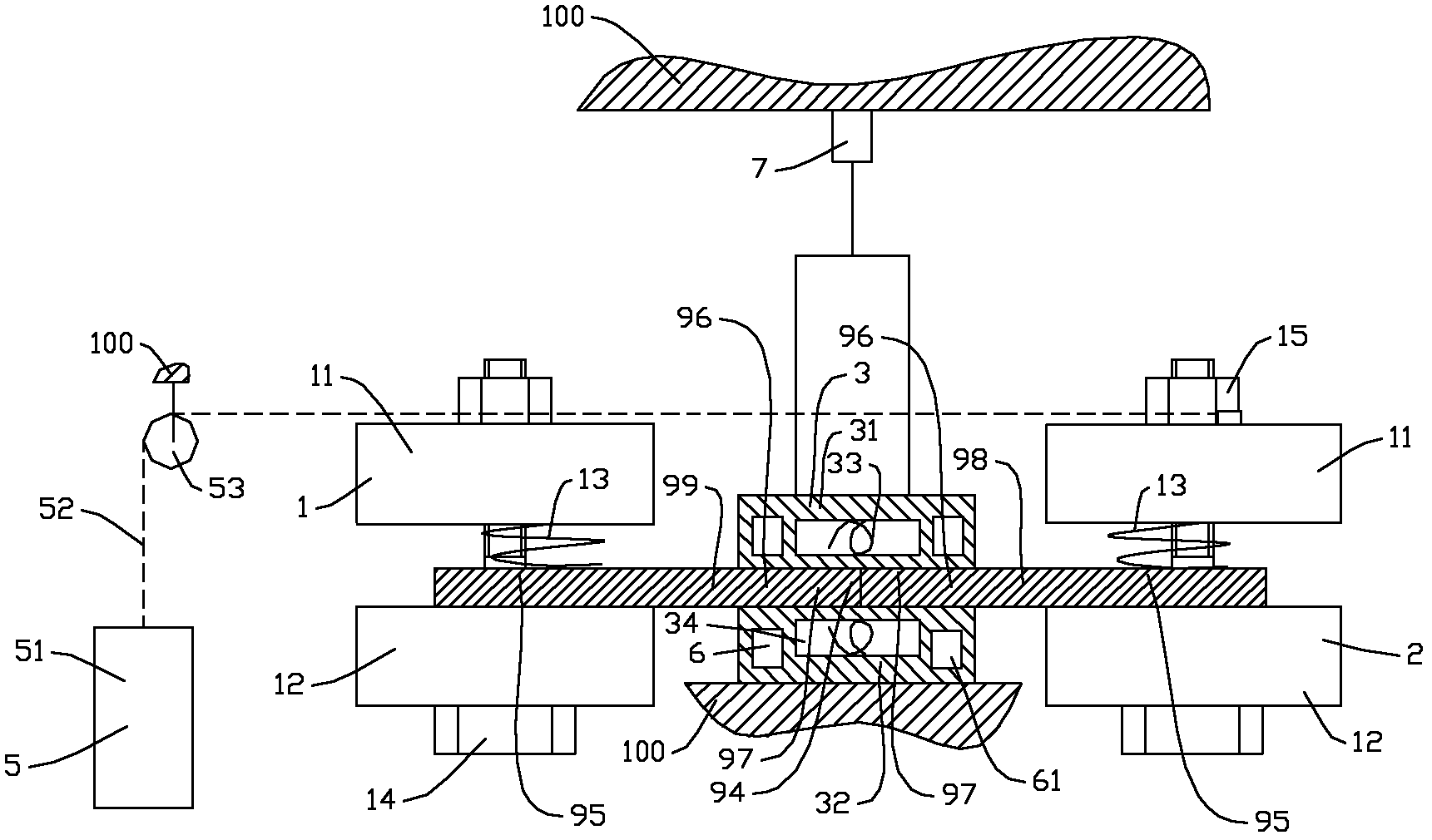

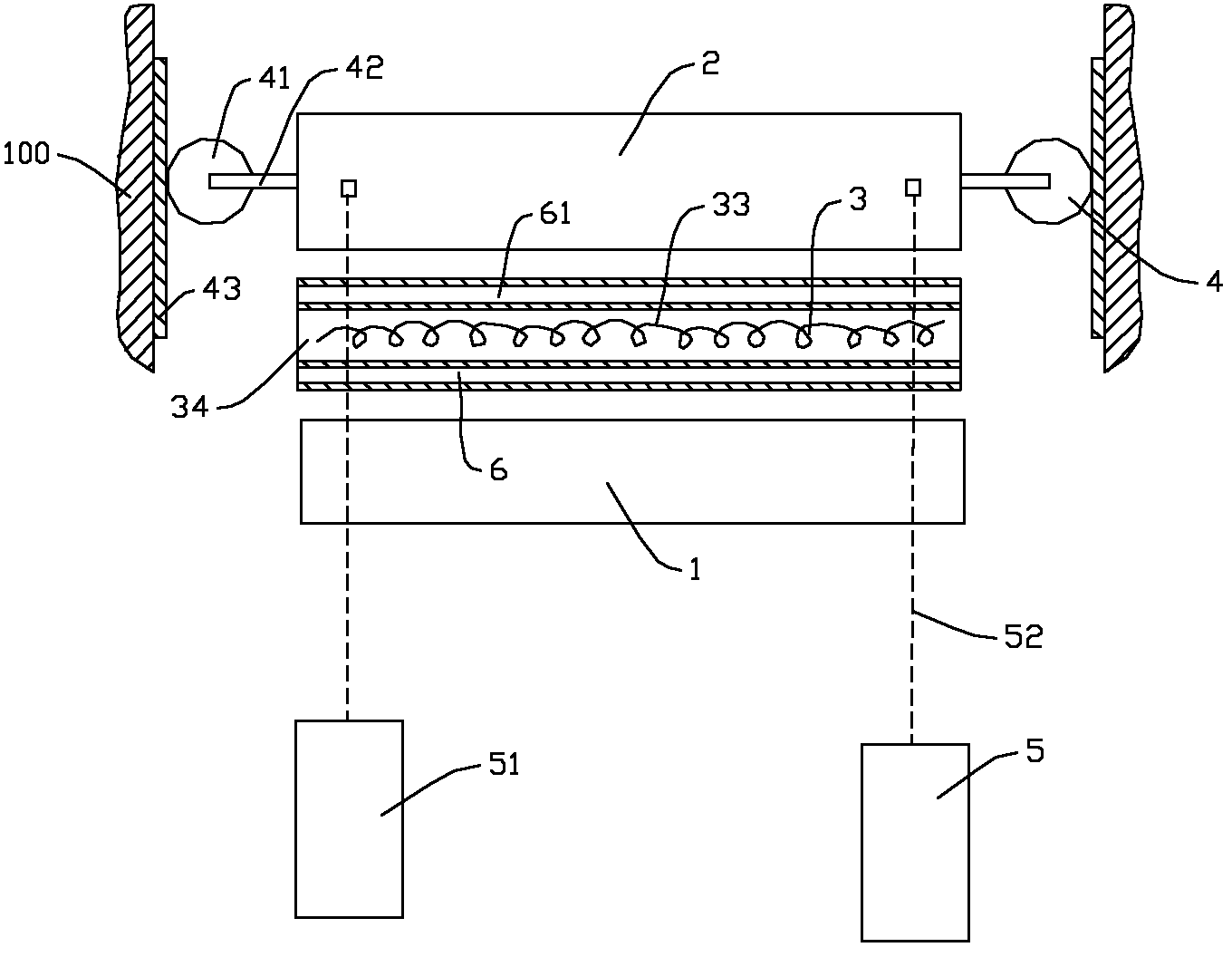

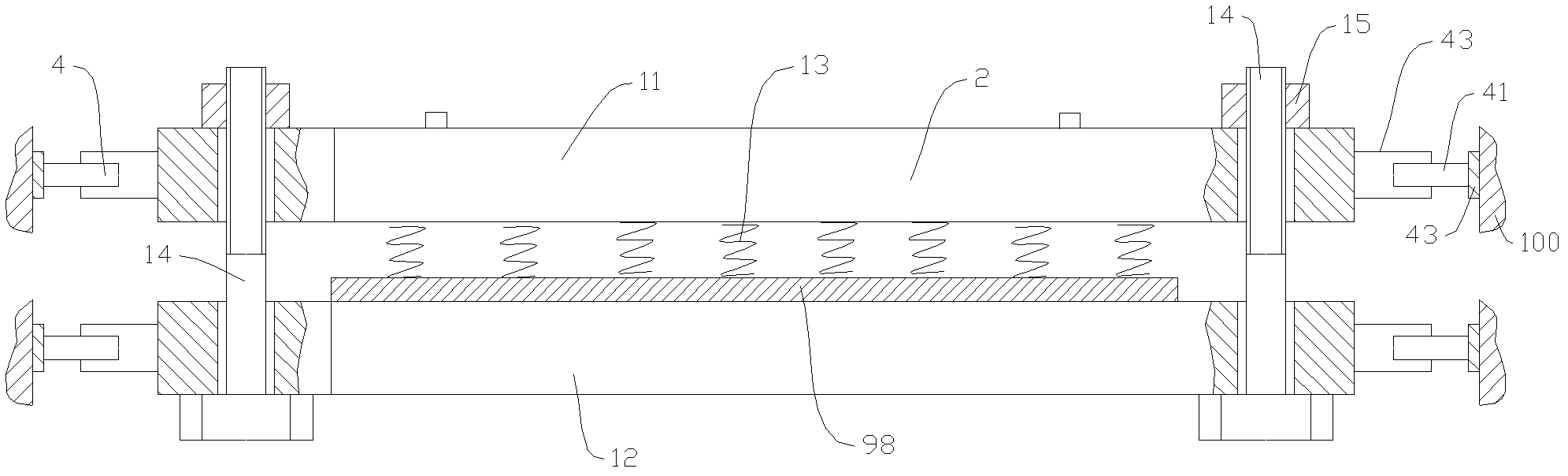

[0032] see figure 1 , 2 The shown PTFE plate welding device includes a frame (100), a fixed plate device (fixing device) 1, a moving plate device (clamping device) 2, a heating device 3, a guiding device 4, a pressurizing device 5, and a cooling device 6 , Oil cylinder (moving device) 7 and so on.

[0033] The fixed plate device 1 has the same structure as the moving plate device (clamping device) 2, and both include an upper pressing plate 11, a lower pressing plate 12, a plurality of compression springs 13, bolts 14, nuts 15 cooperating with the bolts 14, and the like. The compression spring 13 is disposed on the lower surface of the upper pressing plate 11 opposite to the lower pressing plate 12 . Both sides of upper pressing plate 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com