A preparation method of a polyurethane/epoxy resin composite material

A technology of epoxy resin and composite materials, applied in the direction of polyurea/polyurethane adhesives, adhesive types, adhesives, etc., which can solve the problems of reduced bond strength, limited adhesion and heat resistance, poor high temperature resistance, etc. problems, to achieve the effect of improving bonding performance, improving rigidity and comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

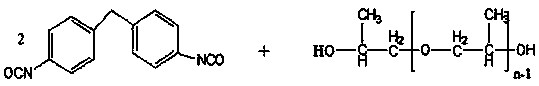

[0028] Implementation of a kind of polyurethane / epoxy resin composite material provided by the present invention, i.e. a kind of preparation method of polyurethane / epoxy resin composite adhesive material, at first is to obtain A Components, and then prepare the binary arylamine-terminated epoxy resin E-44 to obtain the curing agent B component, and finally mix the A and B components in a certain proportion to prepare the polyurethane / epoxy resin composite adhesive agent material. The specific steps are as follows (feeding amount is calculated by mass fraction):

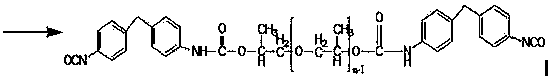

[0029] (1) Synthesis of NCO-terminated MDI-50 type polyurethane prepolymer

[0030] Add 100 parts of polyether polyol N210 into the reactor in parts by mass, and dehydrate for 2.5 hours at 120°C while maintaining a vacuum of 0.08-0.09 MPa; then cool down to 50°C, add 52.2-77.9 parts of diisocyanate, and then heat up to 80 ℃ heat preservation reaction for 2.5 h; control the mass content of free -NCO% to 6.0% ~ 10.0%,...

Embodiment 1

[0064] (1) Synthesis of NCO-terminated MDI-50 type polyurethane prepolymer

[0065] Add 100 parts of polyether polyol N210 into the reactor in parts by mass, dehydrate for 2.5 hours at 120°C while maintaining a vacuum of 0.08-0.09 MPa; then cool down to 50°C, add 52.2 parts of diisocyanate, and then heat up to 80°C Insulation reaction for 2.5 h; when the mass content of free-NCO% is controlled to 6.0%, then degassing under a vacuum of 0.8-0.9 MPa for 0.5 h to obtain -NCO-terminated MDI-50 with a mass content of free-NCO% of 6.0% Polyurethane prepolymer, called A component.

[0066] (2) Synthesis of binary aromatic amine-terminated epoxy resin E-44

[0067] Accurately weigh 272 parts of TX-2 binary aromatic amine in a four-necked bottle, and after heating up to 65±2°C, add 257 parts of E-44 liquid epoxy resin dropwise, keep for 4 to 5 hours to complete the dropping, and then the temperature Rise to 80±2°C, continue to react for 4h to get -NH 2 The blocked curing agent compon...

Embodiment 2

[0071] (1) Synthesis of NCO-terminated MDI-50 type polyurethane prepolymer

[0072] Add 100 parts of polyether polyol N210 into the reactor in parts by mass, dehydrate for 2.5 hours at 120°C while maintaining a vacuum of 0.08-0.09 MPa; then cool down to 50°C, add 77.9 parts of diisocyanate, and then heat up to 80°C Insulation reaction for 2.5 h; when the mass content of free-NCO% was controlled to 10.0%, and then degassed for 0.5 h under a vacuum of 0.8-0.9 MPa, the -NCO-terminated MDI-50 type with a mass content of free-NCO% of 10.0% was obtained Polyurethane prepolymer, called A component.

[0073] (2) Synthesis of binary aromatic amine-terminated epoxy resin E-44

[0074] Accurately weigh 272 parts of binary aromatic amine TX-2 in a four-necked bottle, and after heating up to 65±2°C, add 257 parts of E-44 liquid epoxy resin dropwise, keep the dropwise addition for 4 to 5 hours, and then temperature Rise to 80±2°C, continue to react for 4h to get -NH 2 The blocked curing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com