Tough aldehyde-free soybean meal-based wood adhesive and preparation method thereof

A technology of wood adhesive and aldehyde soybean meal, which is applied in the field of tough aldehyde-free soybean meal based wood adhesive and its preparation, can solve the problems of poor water-resistant bonding performance, free formaldehyde emission of wood-based panels, etc., so as to improve water-resistant bonding Performance, bonding performance improvement, good process performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

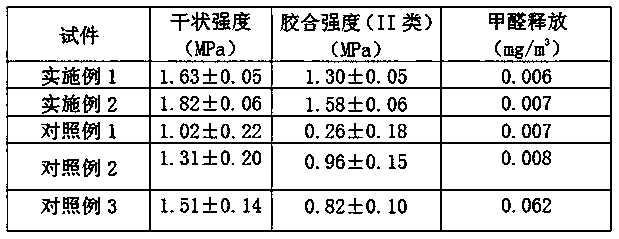

Examples

Embodiment 1

[0033] The present embodiment provides a preparation method of a tough aldehyde-free soybean meal-based wood adhesive, and the adhesive is prepared according to the following weight ratios:

[0034] Modified soybean meal based wood 30 kg

[0035] Branched long chain starch 3 kg

[0036] Polyacrylamide 0.1kg

[0037] Homemade multifunctional epoxy compound 2kg

[0038] Sodium hydroxide solution 0.3kg

[0039] The present embodiment also provides the preparation method of the above-mentioned adhesive, and the specific preparation steps are as follows:

[0040] (1) Weigh the components according to the weight ratio, add the branched long-chain starch into the dispersion medium water, sonicate for 15 minutes, then add half the weight of modified soybean meal-based wood, use a high-pressure homogenizer, under a pressure of 30MPa and 0.5 Under the action of the emulsifying force of MPa, the homogeneous emulsification was carried out for 20 minutes;

[0041] (2) Add the remainin...

Embodiment 2

[0043] The present embodiment provides a preparation method of a tough aldehyde-free soybean meal-based wood adhesive, and the adhesive is prepared according to the following weight ratios:

[0044] Modified soybean meal based wood 33kg

[0045] Branched long chain starch 6kg

[0046] Polyacrylamide 0.2kg

[0047] Homemade Multifunctional Epoxy Compounds 4kg

[0048] Sodium hydroxide solution 0.6kg

[0049] The preparation method of the adhesive described in this example is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com