Fiber reinforced resin composite material, preparation method and applications thereof

A fiber-reinforced resin and composite material technology, which is applied in the field of fiber-reinforced resin composite material preparation, can solve the problems of damage to the properties of organic fibers, high rigidity of impregnated tapes, and increased injection molding costs, and achieves high mechanical properties, improved interfacial adhesion, The effect of improving the bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

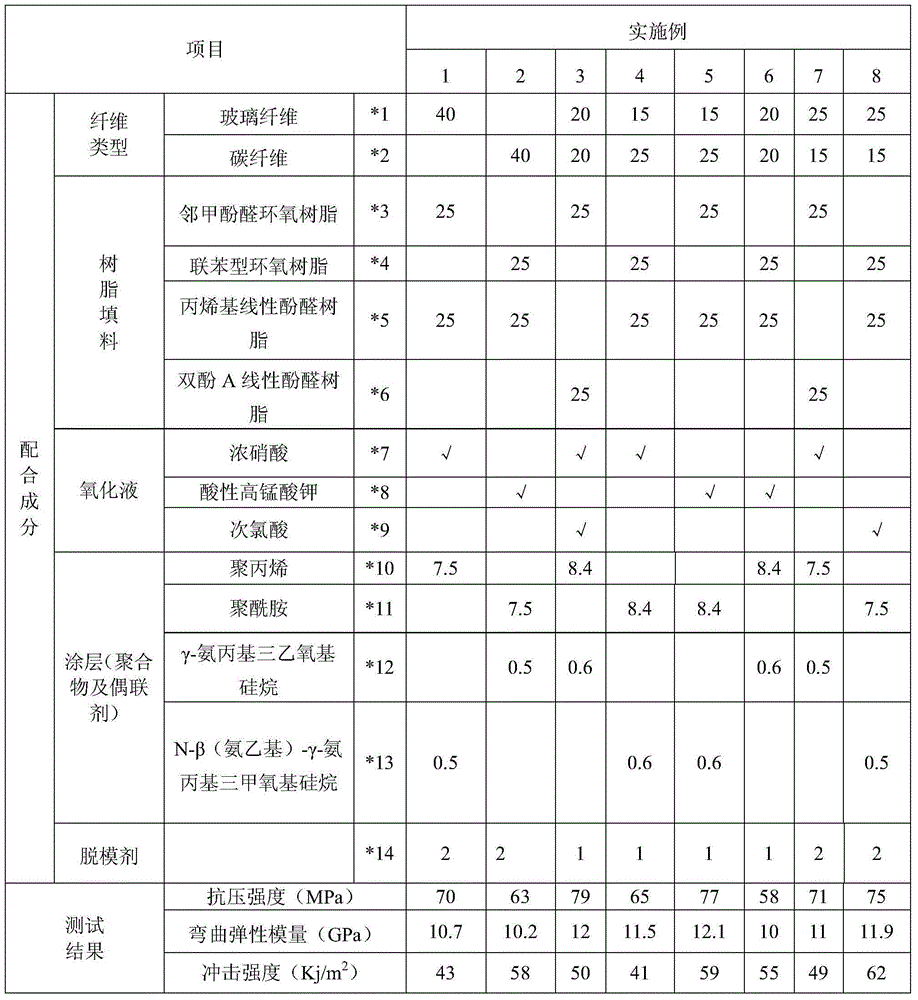

Embodiment 1

[0028] Immerse the glass fibers in an ethanol solution to remove the surface oil of the fibers. The treatment time is 15 minutes. After degreasing, wash the fibers with deionized water and dry them. Then, immerse the glass fiber sample in concentrated nitric acid to reflux for 2 hours, rinse it with deionized water until neutral, dry it in the air, and dry it in a vacuum oven at 105°C. Then polypropylene and N-β(aminoethyl)-γ-aminopropyltrimethoxysilane are fully melted and mixed in a ratio of 15:1 and poured into the spray gun. The oxidized fibers are then passed through a spray chamber. The conveying speed of the fiber is 5m / min, the spraying pressure of the spray gun is 0.35MPa, and the spraying distance is 20cm. The sprayed fibers pass through continuous drying equipment at a drying temperature of 150°C for 3 minutes. The dried fibers are fed into the braiding machine for three-dimensional integral braiding and then put into the mold. Then, the resin filler is mixed uni...

Embodiment 2

[0030] Immerse the carbon fiber in an ethanol solution to remove the oil on the surface of the fiber. The treatment time is 15 minutes. After degreasing, wash and dry the fiber with deionized water. Then, soak the carbon fiber sample in acidic potassium permanganate and reflux for 3 hours, then rinse it with deionized water until it is neutral, dry it in the air, and dry it in a vacuum oven at 105°C. Then polyamide and γ-aminopropyltriethoxysilane are fully melted and mixed at a ratio of 15:1 and poured into the spray gun. The oxidized fibers are then passed through a spray chamber. The conveying speed of the fiber is 5m / min, the spraying pressure of the spray gun is 0.4MPa, and the spraying distance is 25cm. The sprayed fibers pass through continuous drying equipment at a drying temperature of 150°C for 3 minutes. The dried fibers are fed into the braiding machine for three-dimensional integral braiding and then put into the mold. Then, the resin filler is mixed uniformly ...

Embodiment 3

[0032]Immerse glass fibers and carbon fibers in an ethanol solution at a ratio of 1:1 to remove the surface oil of the fibers. The treatment time is 15 minutes. After degreasing, wash the fibers with deionized water and dry them. Then, soak the mixed fiber sample in the mixed solution of concentrated nitric acid and hypochlorous acid to reflux for 2 hours, then rinse it with deionized water until neutral, dry it in the air, and dry it in a vacuum oven at 105 °C. Then fully melt and mix polypropylene and γ-aminopropyltriethoxysilane at a ratio of 14:1, and pour them into the spray gun. The oxidized fibers are then passed through a spray chamber. The conveying speed of the fiber is 5m / min, the spraying pressure of the spray gun is 0.4MPa, and the spraying distance is 25cm. The sprayed fibers pass through continuous drying equipment at a drying temperature of 150°C for 3 minutes. The dried fibers are fed into the braiding machine for three-dimensional integral braiding and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural modulus of elasticity | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com