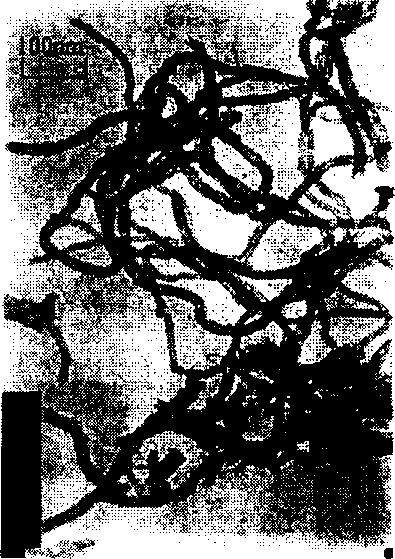

Process for preparing Al2O3 aerogel carried catalyst and its application in preparing nano carbon tubes by catalytic cracking of methane

A supported catalyst and aerogel technology, which is applied in the direction of catalyst activation/preparation, catalyst carrier, chemical instruments and methods, etc., can solve the problems of difficult to achieve large-scale preparation, time-consuming and complicated preparation process, and achieve fine-diameter , The preparation process is simple and the shape is easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Now take the supported Ni catalyst with Ni / Al molar ratio of 1 / 9 as an example to illustrate the specific preparation process:

[0029] Under the condition of vigorous stirring, the molar concentration of Al(NO 3 ) 3 Add dropwise 1.8M ammonia solution in the solution, control the end point pH value to 8, and obtain Can (OH) 3 Sol, continue to react under stirring conditions to obtain aluminum hydroxide gel. Take 0.15MNi(NO 3 ) 2 Solution 34.92ml and a certain amount of ammonia water, under vigorous stirring, add the two solutions into the aluminum hydroxide gel in parallel, after the addition is complete, continue to stir, and control the pH value at 9.3 when the reaction ends. If the bimetallic catalyst is prepared, the two metal nitrate solutions and ammonia water are added to the aluminum hydroxide gel in parallel at this time, and other conditions remain unchanged.

[0030] The prepared gel and active ingredient precipitate were aged for 3 hours under agitation...

Embodiment 2-8

[0033] Embodiment 2-8: The preparation process is the same as that of Embodiment 1, and the changing parameters are shown in Table 1.

[0034] Table 1 Catalyst Preparation Conditions Example Sample Composition Al(NO 3 ) 3 and MNO 3 Concentration End point pH value Supercritical drying conditions 1 Q1 Ni:Al=1:9 0.16M and 0.15M 9.3 Ethanol, 260°C,

[0035] 30min at 7.5Mpa 2 Q2 Ni:Al=2:9 0.16M and 0.15M 9.3 Ethanol, 260°C,

[0036] 30min at 7.5Mpa 3 Q3 Ni:Al=3:9 0.16M and 0.15M 9.4 Ethanol, 260°C,

[0037] 30min at 7.5Mpa 4 Q6 Fe:Al=1:9 0.16M and 0.15M 9.3 Ethanol, 260°C,

[0038] 30min at 7.5Mpa 5 Q6 Fe:Al=2:9 0.16M and 0.15M 9.2 Ethanol, 260°C,

[0039] 30min at 7.5Mpa 6 Q6 Fe:...

Embodiment 9

[0043] Embodiment 9: Preparation process conditions of carbon nanotubes

[0044] Accurately weigh 3.05 mg of 260-270 mesh Q3 (600) catalyst particles and put them into a quartz basket. Purge the residual gas in the system with nitrogen for 10 minutes; feed nitrogen and hydrogen into the system, heat at a rate of 10°C / min to the reduction temperature of 800°C, and reduce to constant weight at constant temperature. The temperature is adjusted to different reaction temperatures in high-purity nitrogen, for example, 550° C. is kept constant, and the reaction gas is fed to prepare carbon nanotubes. Among them: (1) Quartz reactor outer diameter: 24mm; inner diameter: 18mm; (2) Quartz basket height: 12mm; outer diameter: 14mm; ; (4) Reducing gas composition and flow (STP): total flow 45ml / min, H 2 :N 2 It is 1:3 (molar ratio). (5) Reaction gas composition and flow (STP): total flow 45ml / min, CH 4 :N 2 It is 1:2 (molar ratio). (6) Reaction pressure: normal pressure;

[0045] W...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com