Method for preparing Mn2O3 porous micro-nano structure material having controllable morphology

A micro-nano structure and morphology technology, applied in manganese oxide/manganese hydroxide, structural parts, secondary batteries, etc., can solve the problem of rare reports of manganese trioxide anode materials, difficulties in the insertion and extraction of sodium ions, and influence on materials. performance and other issues, to achieve the effect of improving electrochemical performance, maintaining structural integrity, and improving reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] a kind of Mn 2 o 3 Porous micro-nano structure material, its preparation method comprises the following steps:

[0036] 1) Add 0.735g of manganese acetate tetrahydrate into 50mL of deionized water, and stir evenly to obtain solution A;

[0037] 2) Add 1.1g of ammonium bicarbonate into 50mL of deionized water, and stir evenly to obtain solution B;

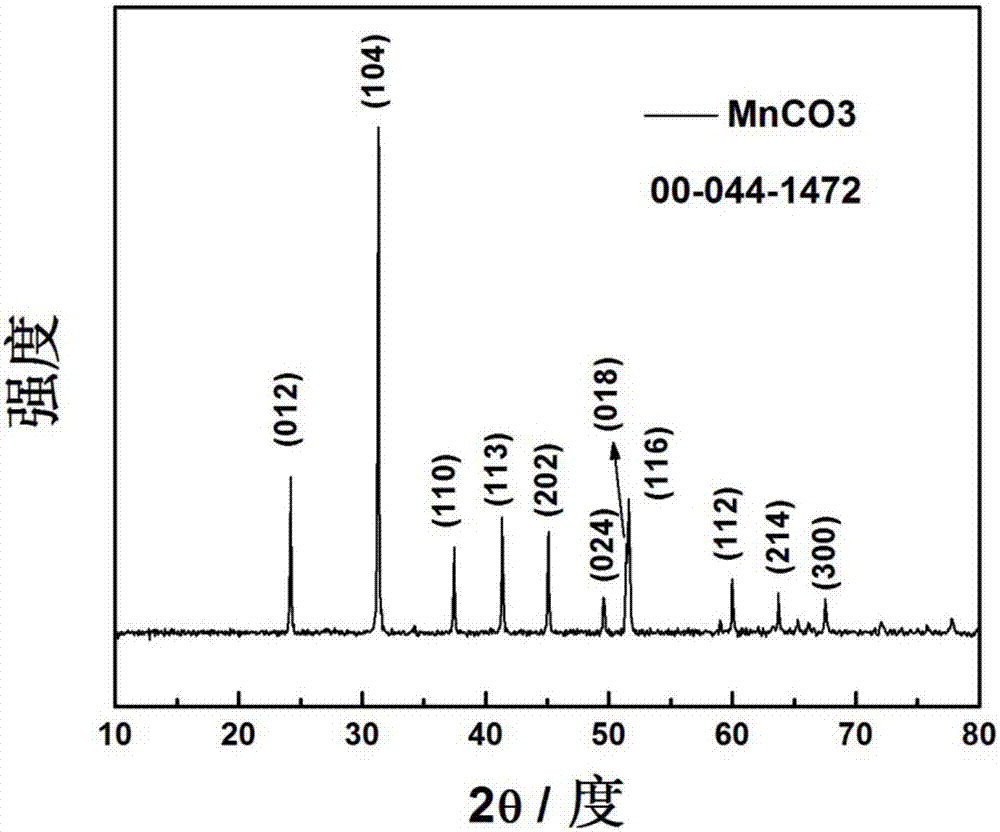

[0038] 3) Under stirring conditions, add solution A dropwise to solution B (the addition rate of manganese acetate solution is 0.1mL / s), and then stir for 30 minutes to produce a white precipitate, then perform suction filtration and place in a 40°C oven Dry to get manganese carbonate;

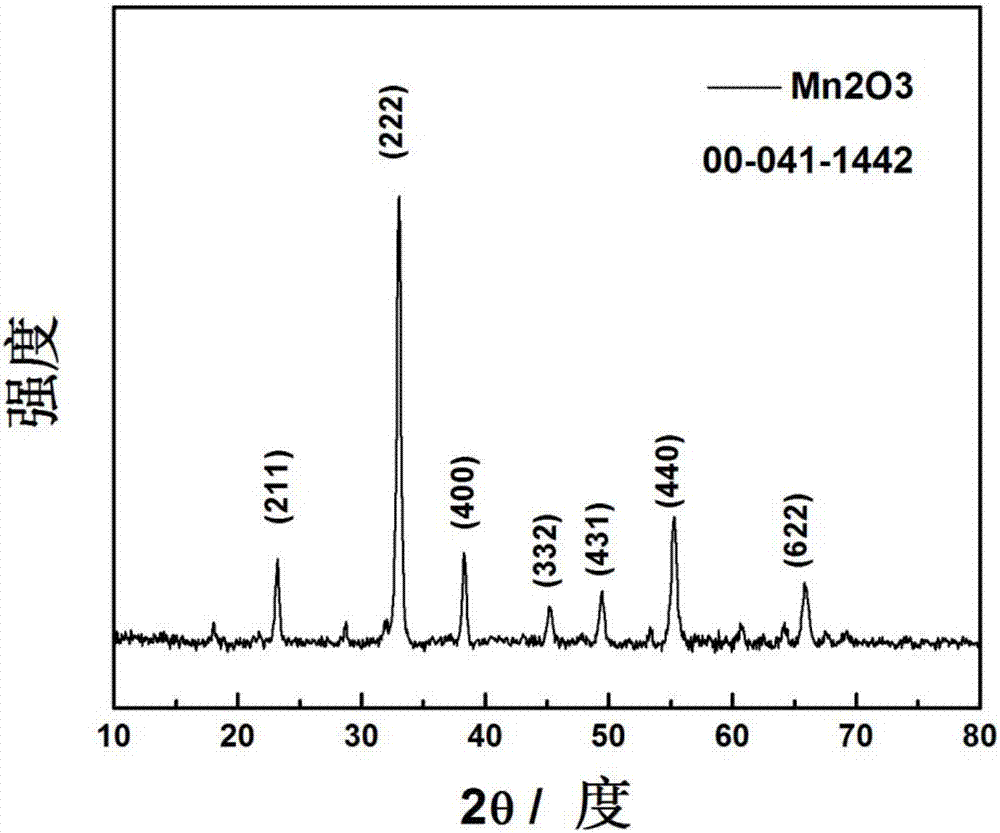

[0039] 4) the manganese carbonate obtained in step 3) is calcined in an air atmosphere to obtain Mn 2 o 3 Porous micro-nano structure material (porous manganese trioxide), wherein the calcination treatment system is: heating at a rate of 3°C / min to 500°C for 4h.

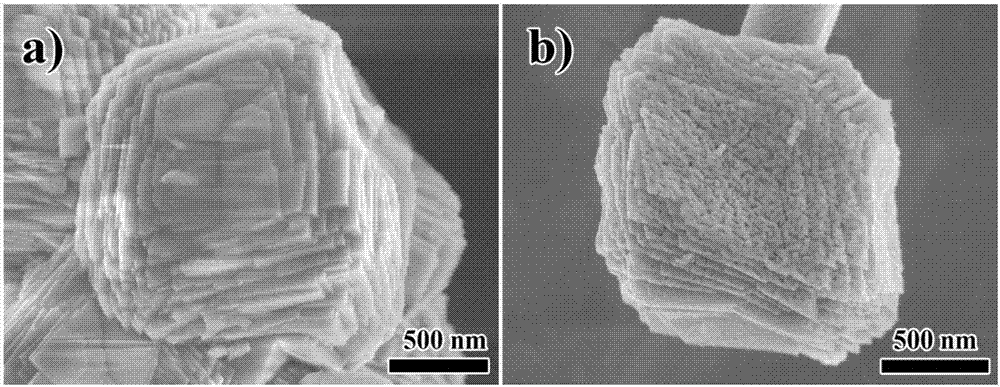

[0040] The obtained manganese carbonate of the present embodiment is carr...

Embodiment 2

[0042] a kind of Mn 2 o 3 Porous micro-nano structure material, its preparation method comprises the following steps:

[0043] 1) Add 0.735g of manganese acetate tetrahydrate into 100mL of deionized water, and stir evenly to obtain solution A;

[0044] 2) Add 0.6g of ammonium bicarbonate into 100mL of deionized water, and stir evenly to obtain solution B;

[0045] 3) Under stirring conditions, add solution A dropwise to solution B (the addition rate of manganese acetate solution is 3.3mL / s), and then stir for 30 minutes to produce a white precipitate, then perform suction filtration and place in an oven at 50°C Dry to get manganese carbonate;

[0046] 4) the manganese carbonate obtained in step 3) is calcined in an air atmosphere to obtain Mn 2 o 3 Porous micro-nano structure material (porous manganese trioxide), wherein the calcination treatment system is: heating at a rate of 3°C / min to 500°C for 4h.

[0047] The obtained manganese carbonate of the present embodiment i...

Embodiment 3

[0049] a kind of Mn 2 o 3 Porous micro-nano structure material, its preparation method comprises the following steps:

[0050] 1) Add 0.735g of manganese acetate tetrahydrate into 400mL of deionized water, and stir evenly to obtain solution A;

[0051] 2) Add 1.1g of ammonium bicarbonate into 400mL of deionized water, and stir evenly to obtain solution B;

[0052] 3) Under stirring conditions, quickly add solution A to solution B (the addition rate of manganese acetate solution is 100mL / s), and then stir for 5 minutes to produce a white precipitate, then carry out suction filtration, and place it in a 60°C oven to dry. get manganese carbonate;

[0053] 4) the manganese carbonate obtained in step 3) is calcined in an air atmosphere to obtain Mn 2 o 3 Porous micro-nano structure material (porous manganese trioxide), wherein the calcination treatment system is: heating at a rate of 3°C / min to 550°C for 3h.

[0054] The obtained manganese carbonate of the present embodiment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesopore diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Mesopore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com