Method for inversion of rock preformed fracture development process

A technology of development process and fissures, which is applied in the field of mine rock mass deformation monitoring and rock fracture mechanics, can solve the problems of inability to visually display the shape of fractured rock mass crack expansion, the mutual influence of monitoring data, and large discreteness. Color dyes and test piece materials are cheap, the principle is simple and easy to understand, and the effect of simple model establishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In the present invention, the method for reversing the development process of rock prefabricated cracks specifically includes the following steps:

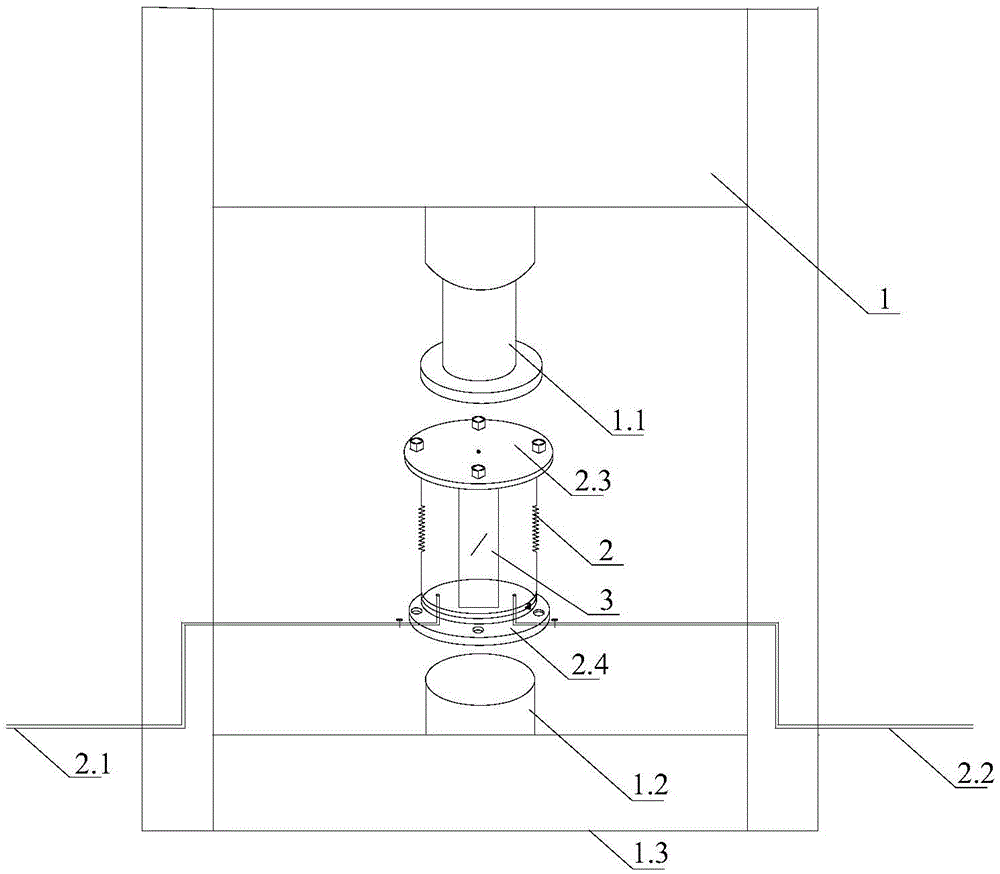

[0045] Step 1, put the prefabricated rock test piece 3 with cracks in the airtight container 2 (extensible), install the top cover 2.3 on the airtight container 2, then place the prefabricated rock test piece 3 with cracks and the airtight container together On the base of the uniaxial press 1 (loading head at the bottom) 1.2;

[0046] Step 2. Adjust the airtight container so that the center of the circle is aligned with the center of the top loading head 11, and connect the color injection inlet and the color injection outlet with the color injection inlet pipe 2.1 and the color injection outlet pipe 2.2 respectively;

[0047] Step 3. According to the design, this test is divided into IV loading stages, namely N=IV.

[0048]Step 4. Before the test starts, first check whether all parts of the test are ready. After they are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com