Lamellar macroporous-mesoporous ZnO nano material and preparation method and application thereof

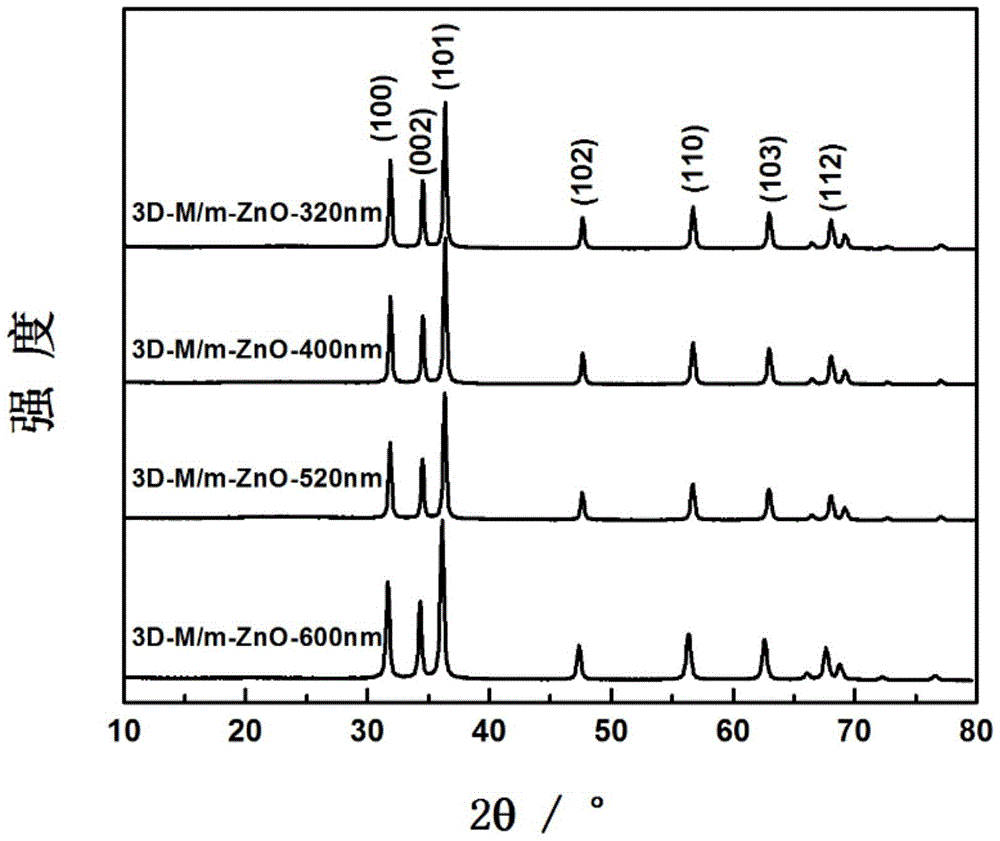

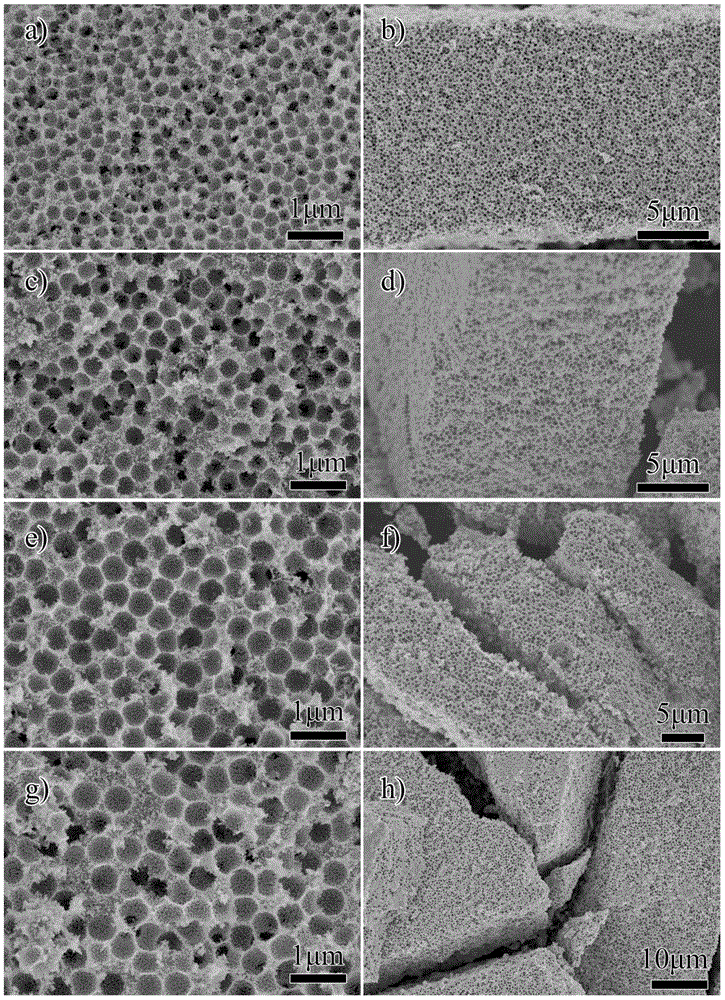

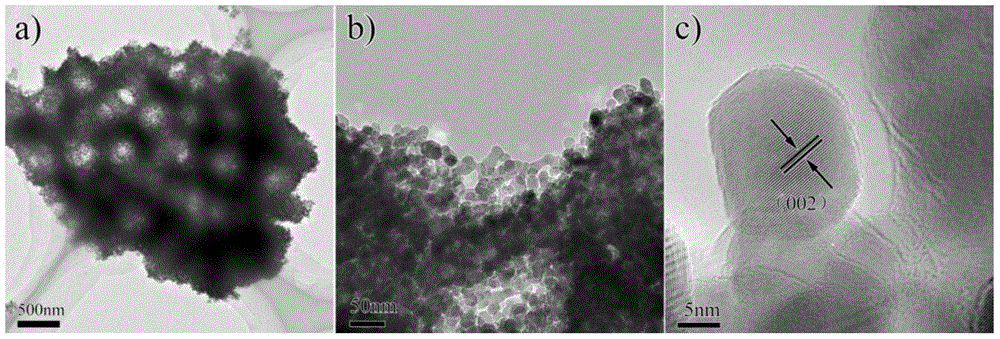

A nano-material and lamellar technology, applied in the field of inorganic nano-functional materials, can solve the problems of three-dimensional porous zinc oxide powder materials such as difficulty in synthesis, uneven size, uncontrollable pore size, etc., to overcome material performance weakening and good crystallinity , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of lamellar three-dimensional macroporous-mesoporous ZnO nanomaterial, its preparation method comprises the steps:

[0037] 1) Preparation of polystyrene-methyl methacrylate-3-sulfonic acid propyl methacrylate potassium template bead solution: 0.4g ammonium persulfate, 0.8g ammonium bicarbonate and 0.05g 3-sulfonic acid propyl methyl Potassium acrylate was dissolved in 10mL of deionized water to obtain solution A; 22.5mL of styrene, 1.25mL of methyl methacrylate and 110mL of deionized water were placed in a 250mL three-necked flask and mixed evenly. 2 When the temperature was raised to 90°C by using an oil bath under the protection of the protection, the temperature was kept for 5 minutes to obtain solution B; then the solution A was quickly added to the solution B according to the volume ratio of 1:11, and the reaction was stirred and kept at 90°C for 9 hours to obtain a uniform emulsion. Remove raw materials that do not participate in the reaction in the gained h...

Embodiment 2

[0042] A kind of lamellar three-dimensional macroporous-mesoporous ZnO nanomaterial, its preparation method comprises the steps:

[0043] 1) Preparation of polystyrene-methyl methacrylate-3-sulfonic acid propyl methacrylate potassium template bead solution: 0.4g ammonium persulfate, 0.8g ammonium bicarbonate and 0.05g 3-sulfonic acid propyl methyl Potassium acrylate was dissolved in 10mL of deionized water to obtain solution A; 22.5mL of styrene, 1.25mL of methyl methacrylate and 110mL of deionized water were placed in a 250mL three-necked flask and mixed evenly. 2 When the temperature was raised to 90°C by using an oil bath under the protection of the protection, the temperature was kept for 5 minutes to obtain solution B; then solution A was quickly added to solution B at a volume ratio of 1:11, stirred and kept for 8 hours at 90°C to obtain a uniform emulsion Remove raw materials that do not participate in the reaction in the gained homogeneous emulsion by distillation unde...

Embodiment 3

[0048] A kind of lamellar three-dimensional macroporous-mesoporous ZnO nanomaterial, its preparation method comprises the steps:

[0049] 1) Preparation of polystyrene-methyl methacrylate-3-sulfonic acid propyl methacrylate potassium template bead solution: 0.4g ammonium persulfate, 0.8g ammonium bicarbonate and 0.06g 3-sulfonic acid propyl methyl Potassium acrylate was dissolved in 10mL of deionized water to obtain solution A; 22.5mL of styrene, 1.25mL of methyl methacrylate and 110mL of deionized water were placed in a 250mL three-necked flask and mixed evenly. 2 When the temperature was raised to 80°C by heating in an oil bath under the protection of the protection, the temperature was kept for 5 minutes to obtain solution B; then solution A was quickly added to solution B according to the volume ratio of 1:12, and the reaction was stirred and kept at 80°C for 7 hours to obtain a uniform emulsion Remove raw materials that do not participate in the reaction in the gained hom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Large hole diameter | aaaaa | aaaaa |

| Mesopore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com