Technology for converting glycerin into lactic acid by aid of NiCu alloy supported catalysts under mild conditions

A supported catalyst and conversion technology, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problem of increasing experiment cost, and achieve cost and The effect of high equipment requirements, simple process flow and simple experimental equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described with specific examples below. The experimental scheme in the present example has no special instructions, and is a conventional method, and the data shown in it do not represent the limitation to the characteristic scope of the present invention simultaneously.

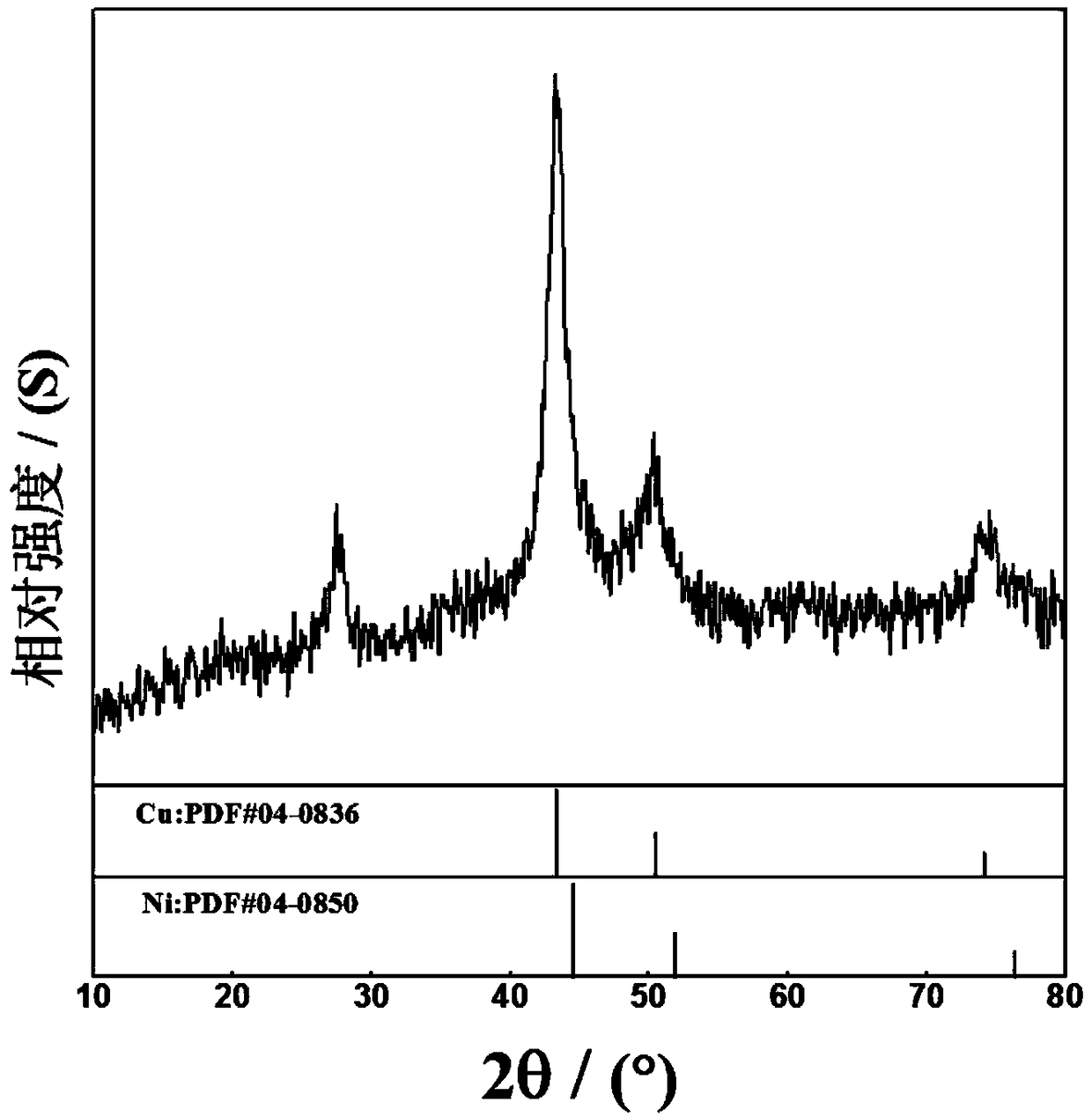

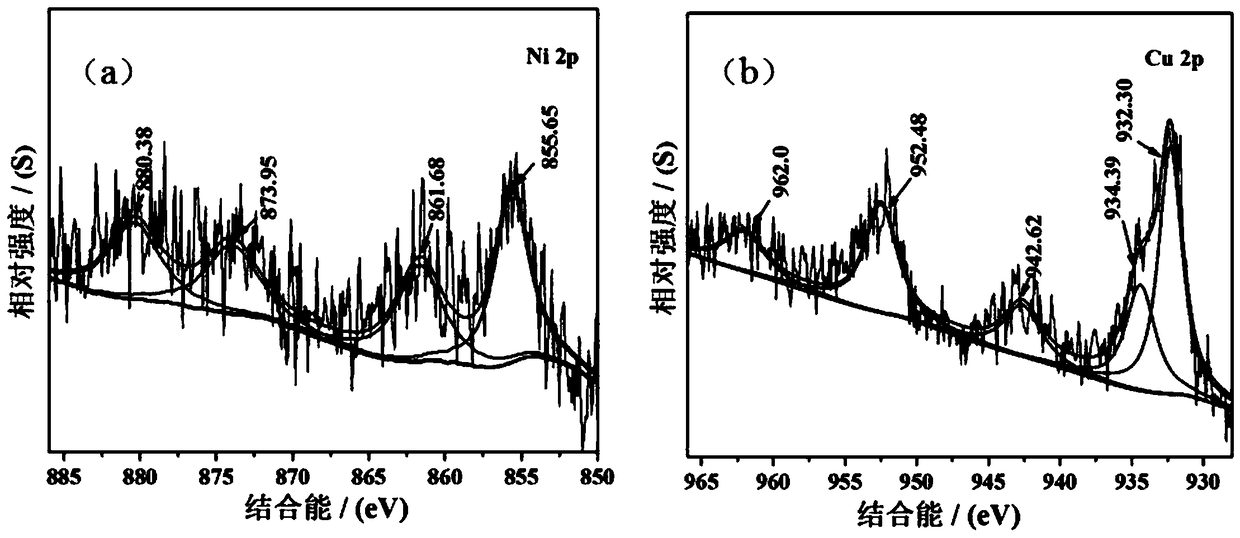

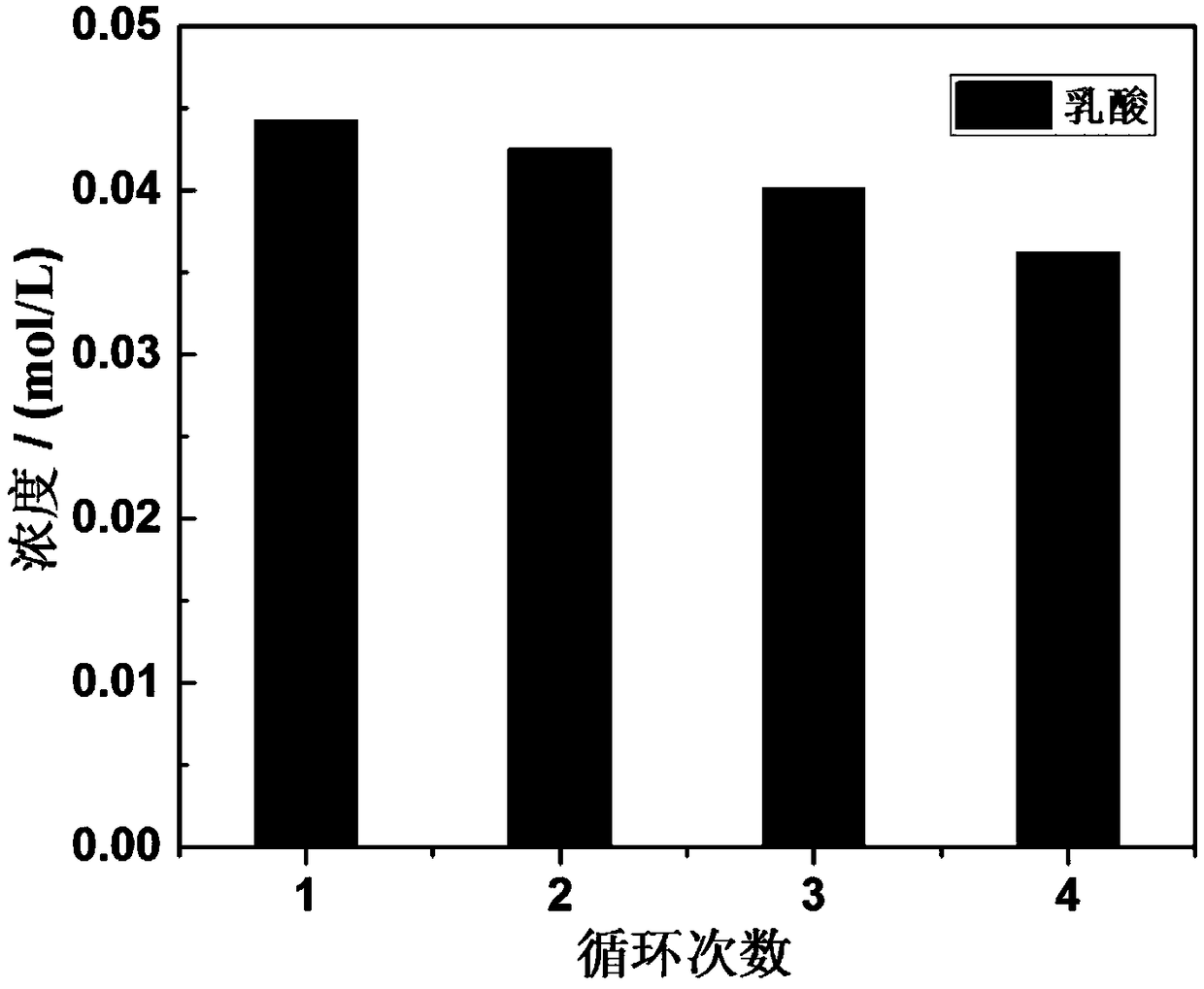

[0022] refer to figure 1 and figure 2 , a kind of technique that utilizes NiCu alloy supported catalyst of the present invention to convert glycerol into lactic acid under mild conditions, comprising the following steps:

[0023] (1) Preparation of support graphite phase carbon nitride of NiCu alloy supported catalyst

[0024] Weigh 10 g of melamine and put it into a crucible, cover the crucible and place it in a muffle furnace, heat up to 580 °C at a rate of 15 °C / min, and calcinate for 4 hours to obtain graphite phase carbon nitride.

[0025] (2) Preparation of NiCu alloy supported catalyst

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com