Preparation method of cadmium selenide or cadmium sulfide two-dimensional monocrystal nanosheet

A single crystal nanometer, cadmium sulfide technology, applied in chemical instruments and methods, single crystal growth, single crystal growth and other directions, can solve the problems of restricting the application of nanometer optoelectronic devices, low crystallinity of nanosheets, and difficult solvent cleaning, etc. R&D and application, easy to make and apply, highly reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Preparation of mica sheet substrate:

[0043] 1. Use scissors to divide the mica sheet into rectangles with a size of 2cm*3cm.

[0044] 2. Use the sharp tweezers at the top to dissociate the mica sheet into two thin sheets naturally from the middle, and use the new dissociated surface as the growth substrate.

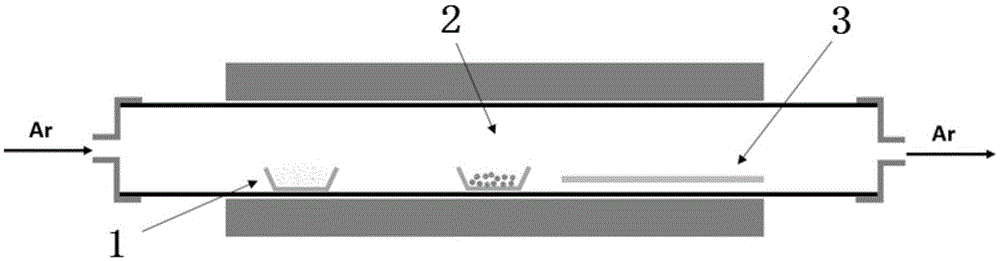

[0045] (2) Weigh 0.1 gram of CdCl 2 powder, which is then placed in the heated central area of a tube furnace. Weigh 0.79 g of Se powder and place it in the ceramic tube about 20 cm upstream from the heating center, and place the mica substrate on the downstream of the heating center of the single-temperature zone tube furnace, about 5-20 cm away from the center.

[0046] (3) Turn on the mechanical pump to evacuate, and when the pressure in the furnace drops to 0.1Pa, quickly fill in high-purity argon to bring the pressure in the chamber back to atmospheric pressure.

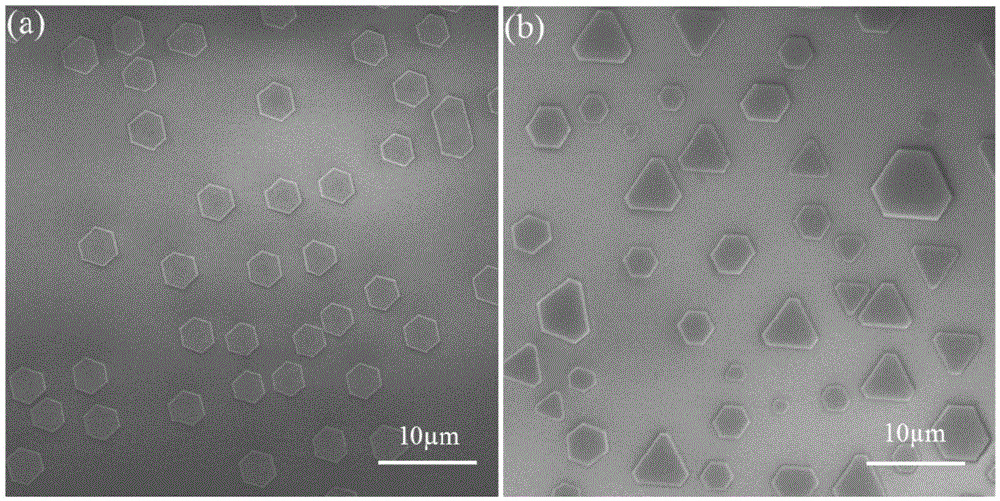

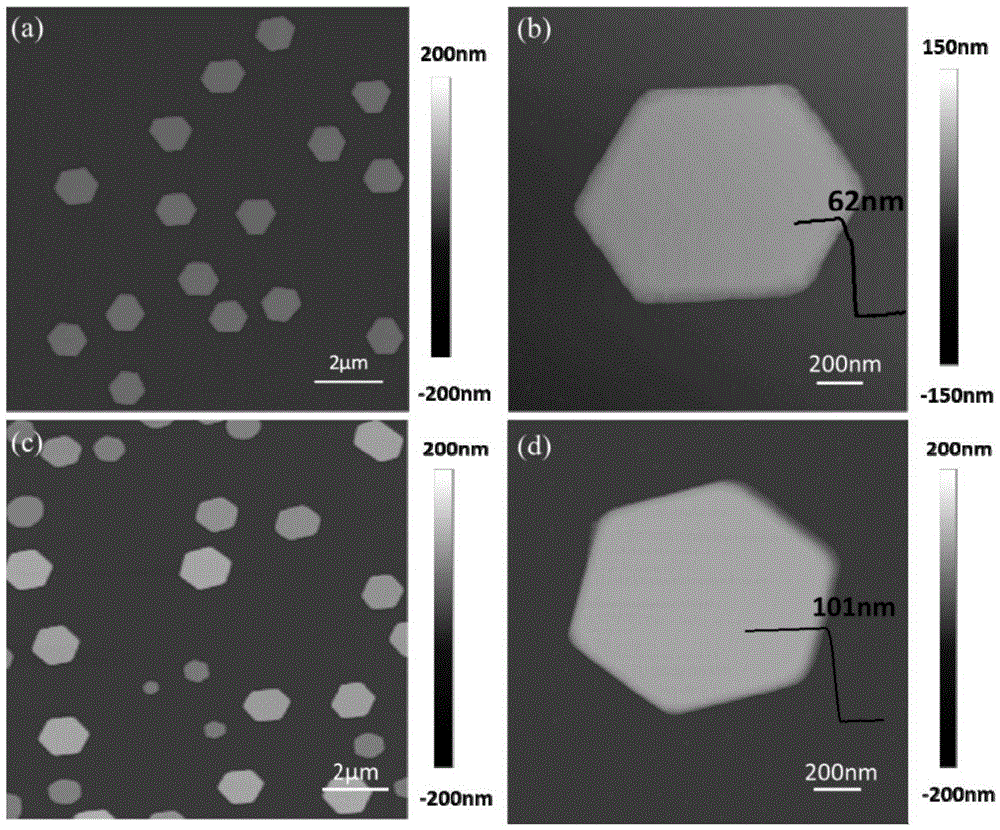

[0047] (4) Rapidly raise the temperature to 750° C. at a speed of 20° C. / min and keep ...

Embodiment 2

[0056] (1) Preparation of mica sheet substrate:

[0057] 1. Use scissors to divide the mica sheet into rectangles with a size of 2cm*3cm.

[0058] 2. Use the sharp tweezers at the top to dissociate the mica sheet into two thin sheets naturally from the middle, and use the new dissociated surface as the growth substrate.

[0059] (2) Weigh 0.1 gram of CdCl 2 powder, which is then placed in the heated central area of a tube furnace. Weigh 0.32 g of S powder and place it in the ceramic tube about 24 cm upstream from the heating center, and place the mica sheet substrate downstream of the heating center of the single-temperature zone tube furnace, about 5-20 cm away from the center.

[0060] (3) Turn on the mechanical pump to evacuate, and when the pressure in the furnace drops to 0.1Pa, quickly fill in high-purity argon to bring the pressure in the chamber back to atmospheric pressure.

[0061] (4) Rapidly raise the temperature to 750° C. at a speed of 20° C. / min and keep it f...

Embodiment 3

[0069] (1) Preparation of mica sheet substrate:

[0070] 1. Use scissors to divide the mica sheet into rectangles with a size of 2cm*3cm.

[0071] 2. Cleavage the mica sheet into two sheets naturally from the middle with the tipped tweezers, and use the new cleavage plane as the growth substrate.

[0072] (2) Weigh 0.1 gram of CdCl 2 powder, which is then placed in the heated central area of a tube furnace. Weigh 0.79 g of selenium powder and place it in the ceramic tube about 26 cm upstream from the heating center, and place the mica sheet substrate sequentially on the downstream of the heating center of the single temperature zone tube furnace, about 5-20 cm away from the center.

[0073] (3) Turn on the mechanical pump to evacuate, and when the pressure in the furnace drops to 0.1Pa, quickly fill in high-purity argon to bring the pressure in the chamber back to atmospheric pressure.

[0074] (4) Rapidly raise the temperature to 800° C. at a speed of 30° C. / min and keep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com