Ballast intelligent screening device based on particle morphology identification

A particle shape and screening device technology, applied in the field of railway engineering, can solve problems such as limitations, low measurement accuracy and efficiency, and inability to accurately reflect the geometric characteristics of ballast, so as to improve ballast screening efficiency and reduce labor costs. The effect of controllable labor intensity and ballast shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

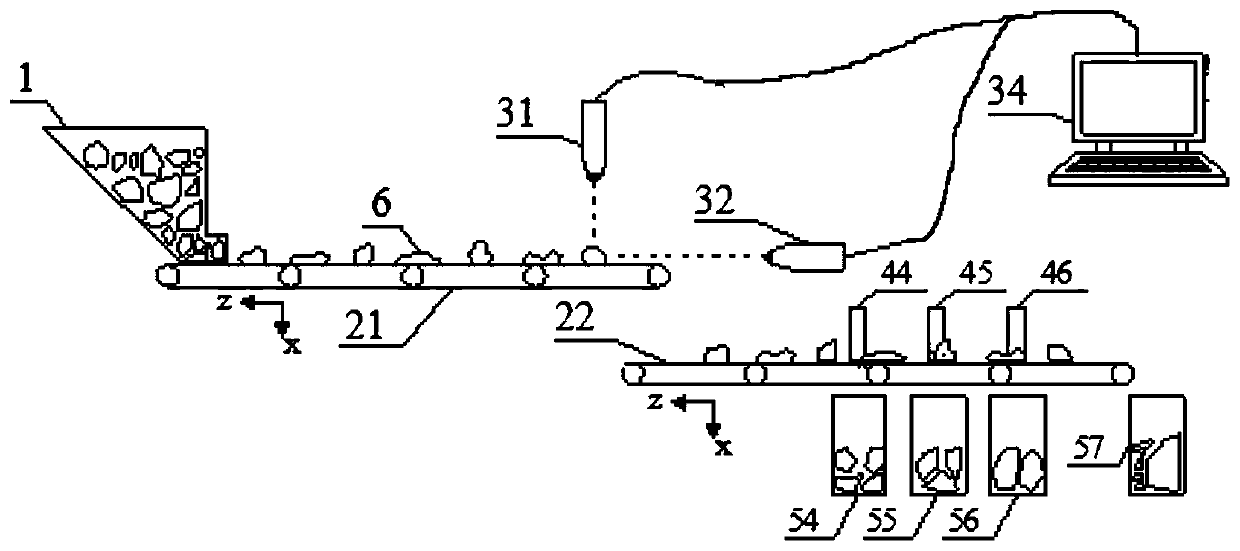

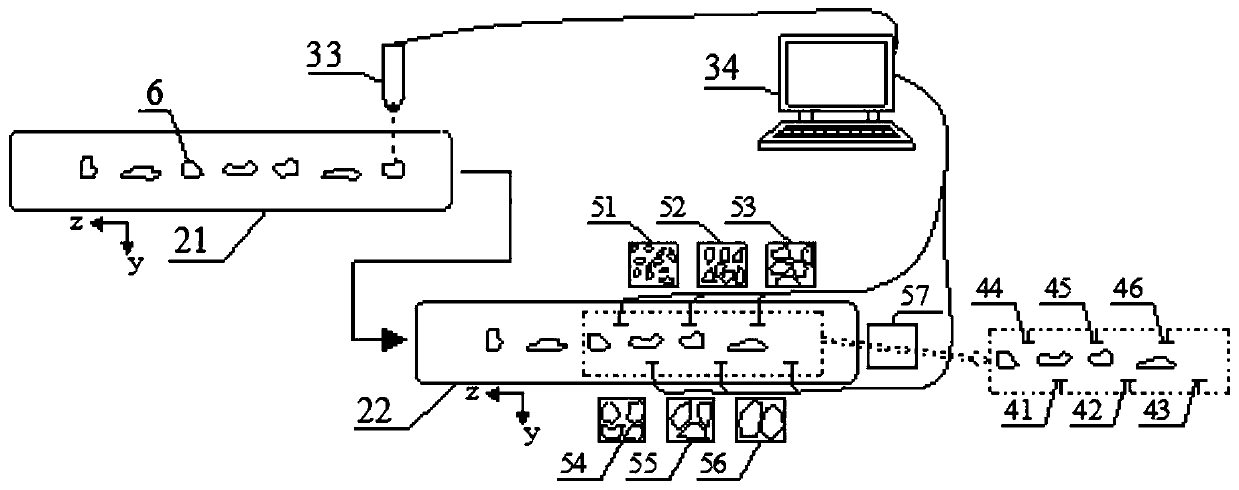

Method used

Image

Examples

Embodiment 1

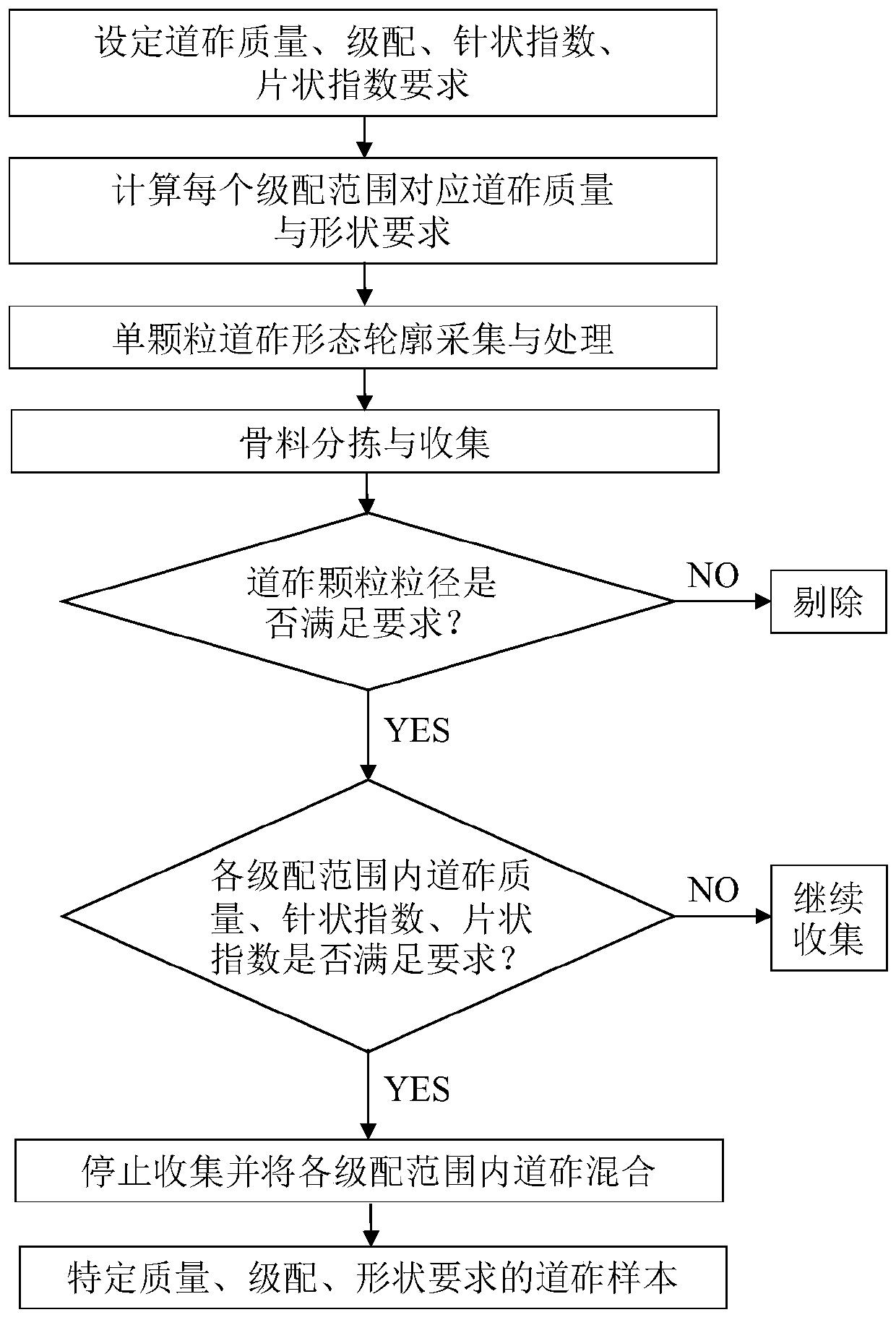

[0075] In order to carry out the indoor direct shear test of ballast particles, it is planned to screen a 50kg ballast sample for the test of the first-class crushed stone ballast of the new railway, and the ballast sample gradation, needle index, and flake index are required to meet the specification requirements .

[0076] "Railway Ballast Ballast" (TB / T 2140-2008) stipulates that the particle size distribution of the first-grade ballast ballast for new railways should meet the requirements in Table 1.

[0077] Table 1 Gravel size distribution of first-class gravel ballast for newly built railways

[0078]

[0079] In addition, "Railway Ballast" (TB / T 2140-2008) also stipulates the maximum content of needle index and flake index of ballast, requiring that the needle index of ballast should not exceed 20%, and the flake The index is not greater than 20%. Among them, the acicular index is defined as the mass percentage of particles whose length (maximum size) is greater t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com