Preparation method of spherical nickel diselenide powder

A technology of nickel diselenide and powder, which is applied in the field of preparation of spherical nickel diselenide powder, can solve the problems of restricting large-scale application and material pulverization, and achieve controllable shape, mild reaction and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 0.2379g (0.05mol / L) nickel chloride hexahydrate and 0.3159g (0.004mol) elemental selenium to 20mL of a mixed solvent of ethylenediamine and 80% hydrazine hydrate with a volume ratio of 1: 3, sonicate for 30min, and stir After uniformity, the reaction solution was transferred to a 25 mL high-pressure reactor with a polytetrafluoroethylene liner, the reactor was sealed, and placed in an oven for reaction at 140° C. for 15 hours. The obtained product is washed with ethanol and distilled water for 2-3 times, and then dried at 60°C-80°C to obtain spherical nickel diselenide powder.

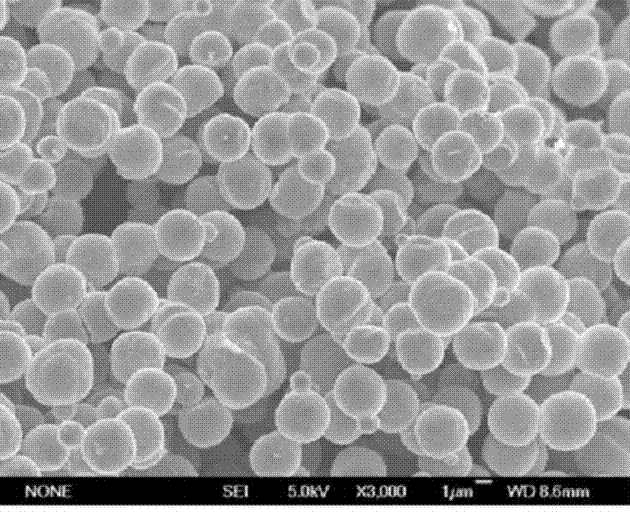

[0033] The morphology of the samples obtained under different conditions was characterized by JEOL JSM-6700F scanning electron microscope (SEM) in Japan, and the phase characterization of the samples obtained under different conditions was carried out by Rigaku D / max 2200 X-ray diffractometer (XRD) in Japan. figure 1 It is a typical SEM image of the sample in Example 1. It can be clearly see...

Embodiment 2

[0035] Add 0.2379g (0.05mol / L) nickel chloride hexahydrate and 0.4738g (0.006mol) elemental selenium to 20mL of a mixed solvent of ethylenediamine and 80% hydrazine hydrate with a volume ratio of 1:6, and ultrasonically shake for 30min. After stirring evenly, the reaction solution was transferred to a 25mL autoclave lined with polytetrafluoroethylene, and the autoclave was sealed, put into an oven, and reacted at 100°C for 20h. The obtained product is washed with ethanol and distilled water for 2-3 times respectively, and then dried at 60°C-80°C to obtain spherical nickel diselenide powder.

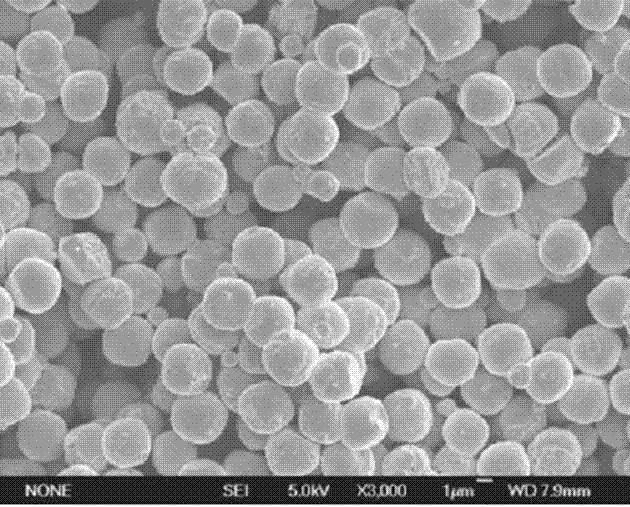

[0036] The morphology of the samples obtained under different conditions was characterized by JEOL JSM-6700F scanning electron microscope (SEM) in Japan, and the phase characterization of the samples obtained under different conditions was carried out by Rigaku D / max 2200 X-ray diffractometer (XRD) in Japan. figure 2 It is a typical SEM image of the sample in Example 2. It can be clearly...

Embodiment 3

[0038] Add 0.2379g (0.05mol / L) nickel chloride hexahydrate and 0.6317g (0.008mol) elemental selenium to 20mL of a mixed solvent of ethylenediamine and 80% hydrazine hydrate with a volume ratio of 1:4, and ultrasonically shake for 30min. After stirring evenly, the reaction solution was transferred to a 25mL autoclave lined with polytetrafluoroethylene, the autoclave was sealed, and put into an oven to react at 180°C for 10h. The obtained product is washed with ethanol and distilled water for 2-3 times respectively, and then dried at 60°C-80°C to obtain spherical nickel diselenide powder.

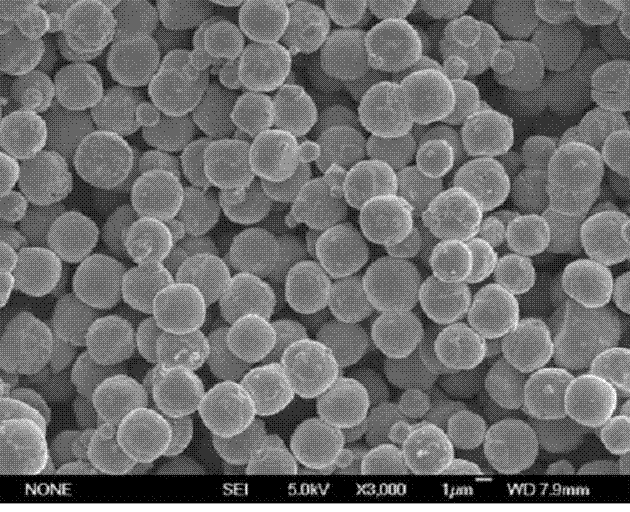

[0039] The morphology of the samples obtained under different conditions was characterized by JEOL JSM-6700F scanning electron microscope (SEM) in Japan, and the phase characterization of the samples obtained under different conditions was carried out by Rigaku D / max 2200 X-ray diffractometer (XRD) in Japan. image 3 It is a typical SEM picture of the sample in Example 3. It can be clearly se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com