AI-Zr-B-O reacting system for synthesizing high-performance aluminium-base copmosite material in-situ and synthetic material thereof

A technology of in-situ composite materials and aluminum-based composite materials, which is applied in the field of reaction systems for new synthetic composite materials, can solve the problems of high initial reaction temperature, deterioration of aluminum liquid, etc., and achieve the effects of stable reaction, clean interface and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

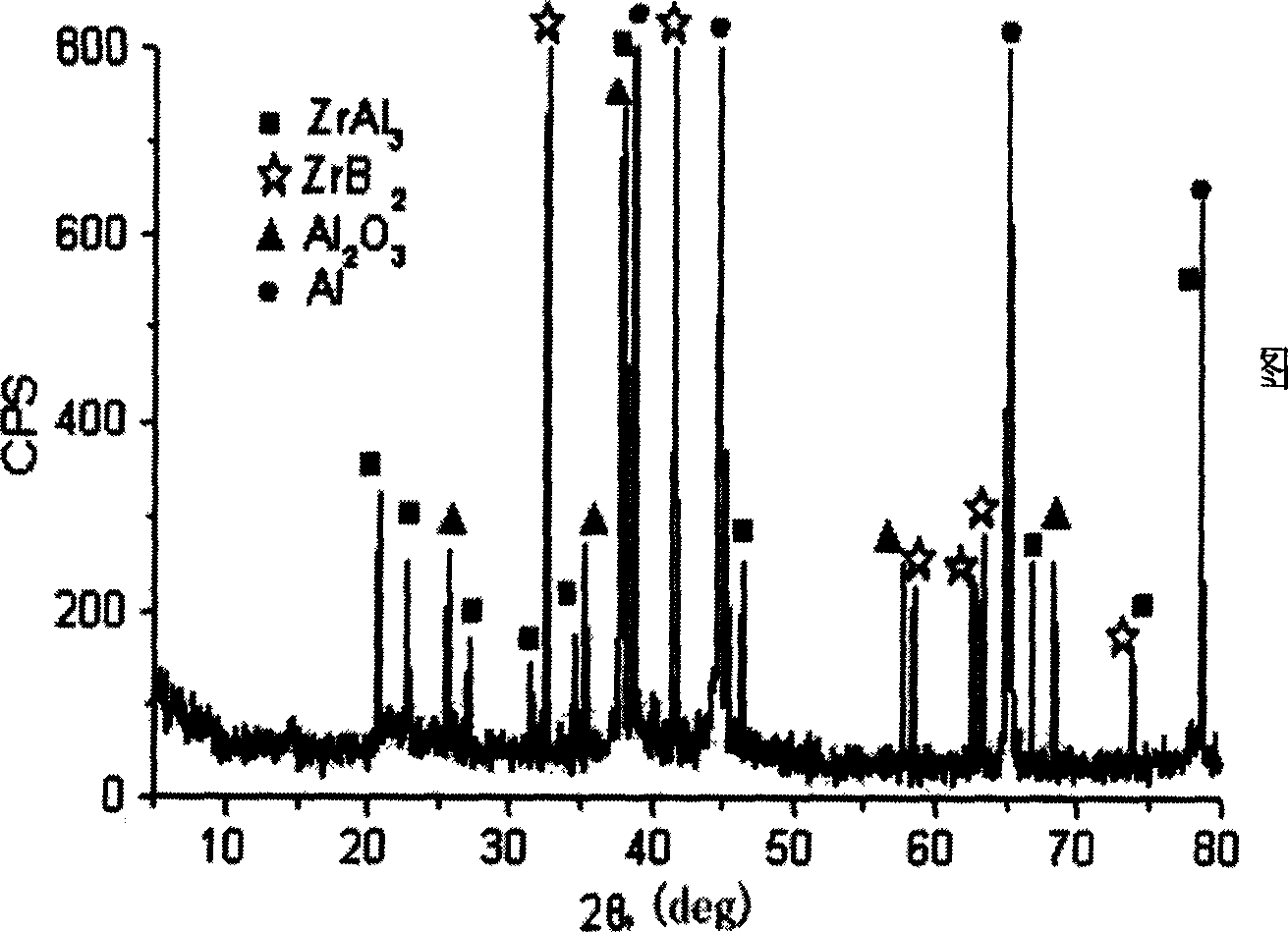

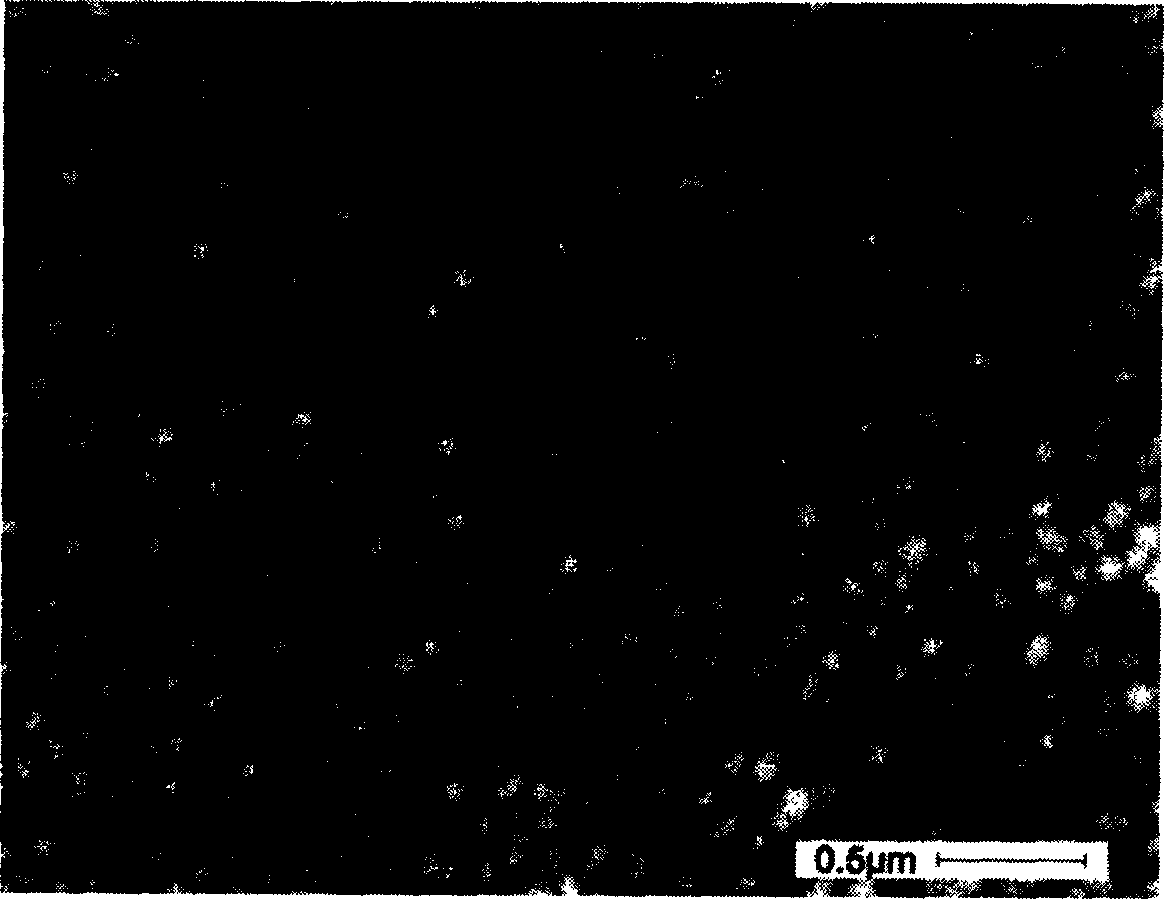

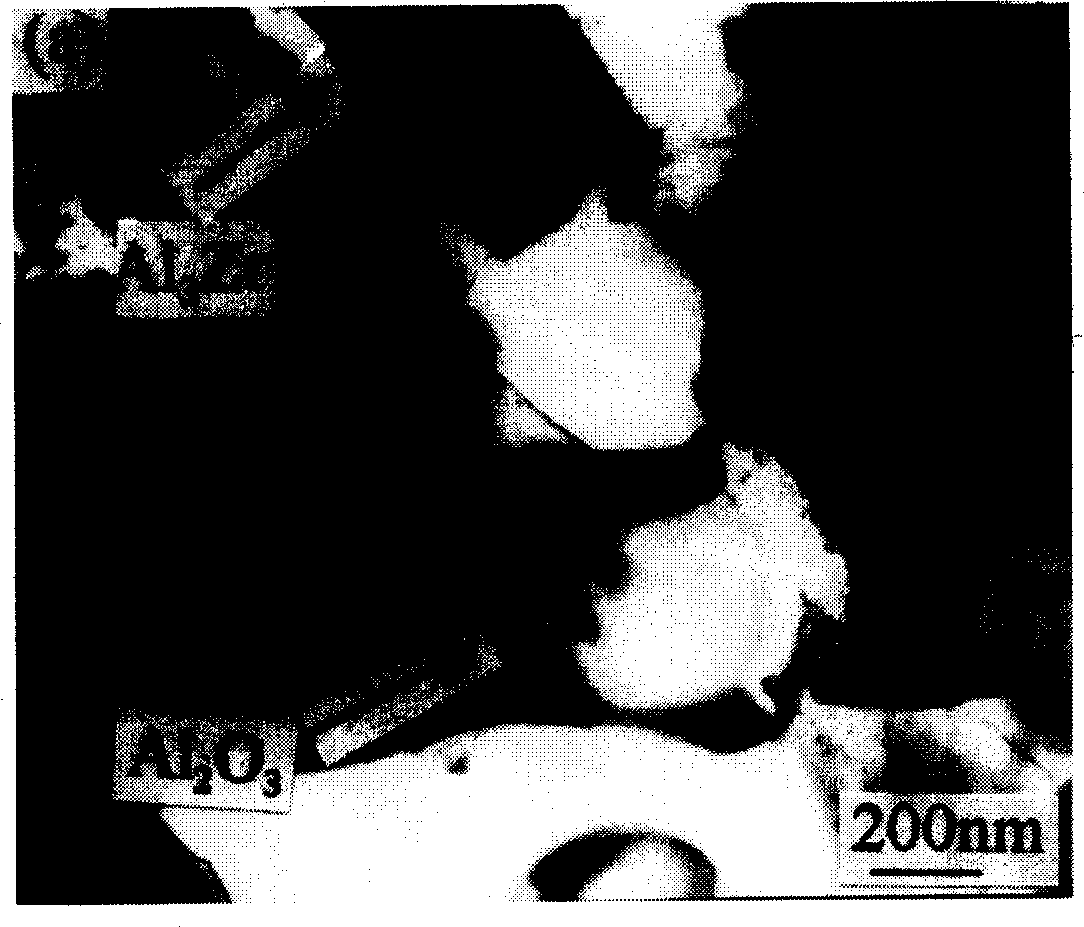

[0016] Embodiment 1: The metal aluminum in the crucible is melted by heating to 850° C. in a resistance furnace. After the molten aluminum is refined and left to stand, the zirconia (ZrO 2 ) and boron oxide (B 2 o 3 ) powder (the purity of the powder is 99%, and the average particle size is 80 μm) mixed and stirred evenly, wherein ZrO 2 , B 2 o 3 According to Zr, B molar ratio 1:1 mixed. Then preheat at 200° C. for 2 hours, and use a pneumatic conveying method to feed into the molten aluminum liquid through a catheter for reaction, thereby forming an Al-Zr-B-O reaction system. During the transportation process, argon is used as a protective gas, and a graphite stirring rod is used for stirring at the same time. After the Al-Zr-B-O reaction system was fully reacted for 30 minutes, it was refined with nitrogen for 8 minutes, and then poured into a metal mold to prepare (ZrAl 3 +ZrB 2 +Al 2 o 3 ) particle-reinforced aluminum-based composite material, wherein the overall...

Embodiment 2

[0017] Embodiment 2: Heating to 870° C. in a resistance furnace to melt the metal aluminum in the crucible. After the molten aluminum is refined and left to stand, the zirconia (ZrO 2 ) and potassium fluoroborate (KBF 4 ) powder (the purity of the powder is 99%, and the average particle size is 80 μm) mixed and stirred evenly, wherein ZrO 2 、KBF 4 According to Zr, B molar ratio 1:2 mixed. Then preheat at 200° C. for 2 hours, and use a pneumatic conveying method to feed into the molten aluminum liquid through a catheter for reaction, thereby forming an Al-Zr-B-O reaction system. During the transportation process, argon is used as a protective gas, and a graphite stirring rod is used for stirring at the same time. After the Al-Zr-B-O reaction system was fully reacted for 30 minutes, it was refined with nitrogen for 8 minutes, and then poured into a metal mold to prepare (ZrAl 3 +ZrB 2 +Al 2 o 3 ) particle-reinforced aluminum-based composite material, wherein the overall ...

Embodiment 3

[0018] Embodiment 3: The A356 alloy in the crucible is melted by heating to 890° C. in a resistance furnace. After refining the molten A356 alloy and standing still, the zirconium silicate (ZrSiO 4 ) and boron oxide (KBF 4 ) powder (purity 99%, average particle size 80μm) mixed and stirred evenly, ZrSiO 4 、KBF 4 According to Zr, B molar ratio 1:2 mixed. Then preheat at 200° C. for 2 hours, and use the pneumatic conveying method to feed the A356 alloy melt into the molten A356 alloy for reaction, thereby forming an Al-Zr-B-O reaction system. During the transportation process, argon is used as a protective gas, and a graphite stirring rod is used for stirring at the same time. After the Al-Zr-B-O reaction system was fully reacted for 30 minutes, it was refined with nitrogen for 8 minutes, and then poured into a metal mold to prepare (ZrAl 3 +ZrB 2 +Al 2 o 3 ) particle-reinforced A356 alloy-based composite material, the total volume fraction of reinforcing particles is 8....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com