In-situ microfibrillar polypropylene series resin composite foamed particles and application thereof

A polypropylene resin and composite foaming technology, applied in the field of foaming materials, can solve the problem of high in-mold molding pressure, and achieve the effects of high production efficiency, automatic production and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

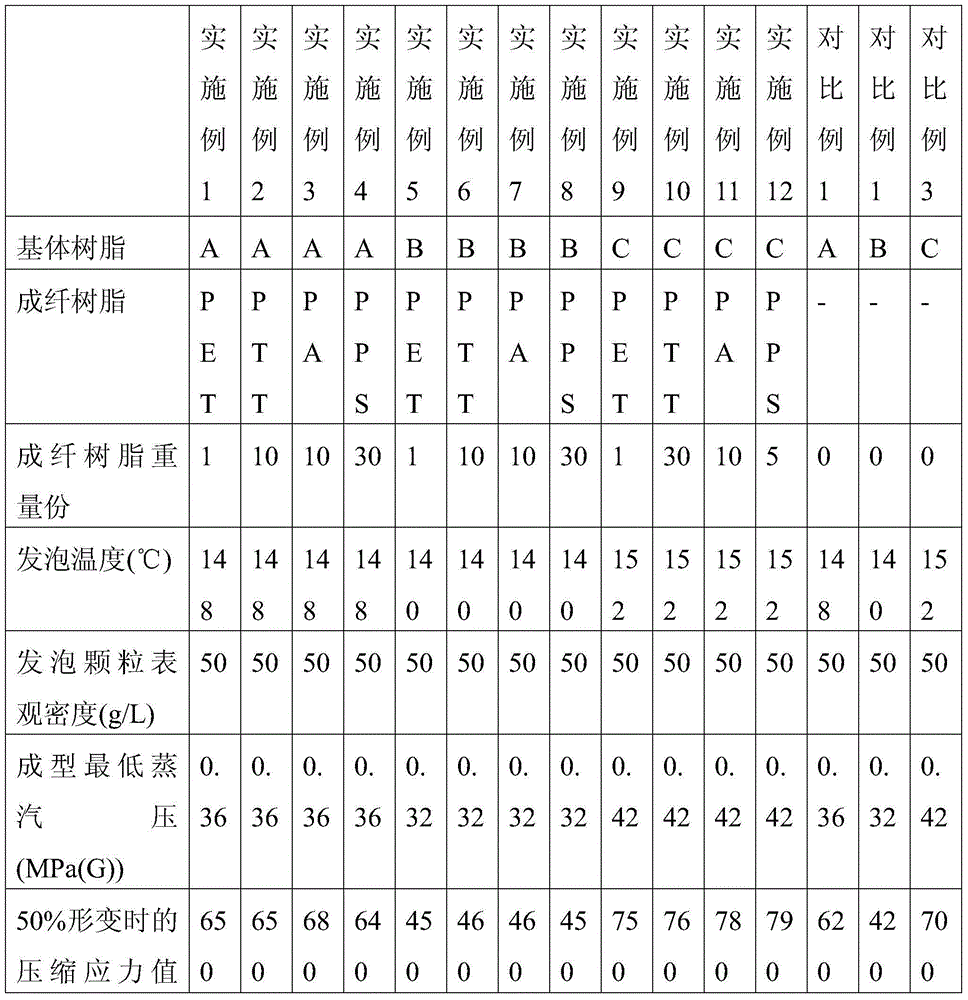

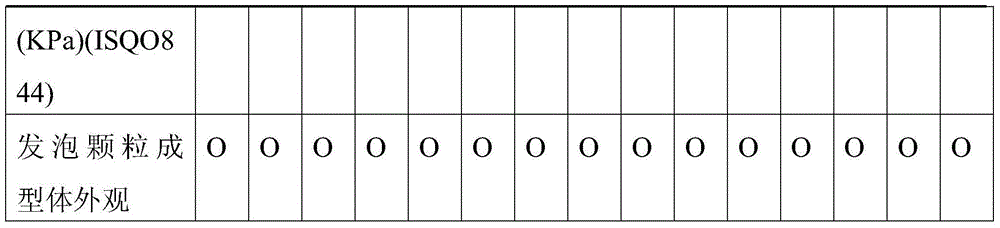

Embodiment 1-12

[0033] Preparation of in-situ microfibrillated polypropylene resin composite foam particles:

[0034] Step 1. According to the composition and proportion of Table 1, add 100 parts by weight of matrix resin and fiber-forming resin to the extruder, heat to melt, and extrude the melt linearly. The melt is thermally stretched, quenched, and pelletized to obtain in-situ microfibrillated polypropylene blended resin particles with a diameter of 1 mm, a length of 1.8 mm, and an average weight of 1.8 mg;

[0035] Step 2: Add 100 parts by weight (1000 g) of the above-mentioned in-situ microfibrillated polypropylene blend resin particles, 300 parts by weight of water, 0.05 parts by weight of sodium dodecylbenzenesulfonate, and 0.3 parts by weight of kaolin to a 5L autoclave and carbon dioxide (the carbon dioxide charged ensures that the pressure in the autoclave at the foaming temperature is 6MPa), while stirring, the temperature is raised to a temperature 5°C lower than the foaming temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com