Preparation method of composite gel micro-spheres as well as composite gel micro-spheres and application thereof

A technology of composite gel and microspheres, which is applied in the directions of inactive medical preparations, pharmaceutical formulations, inactive high molecular compounds, etc. glue and other problems, to achieve the effect of low cytotoxicity, increased strength, and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

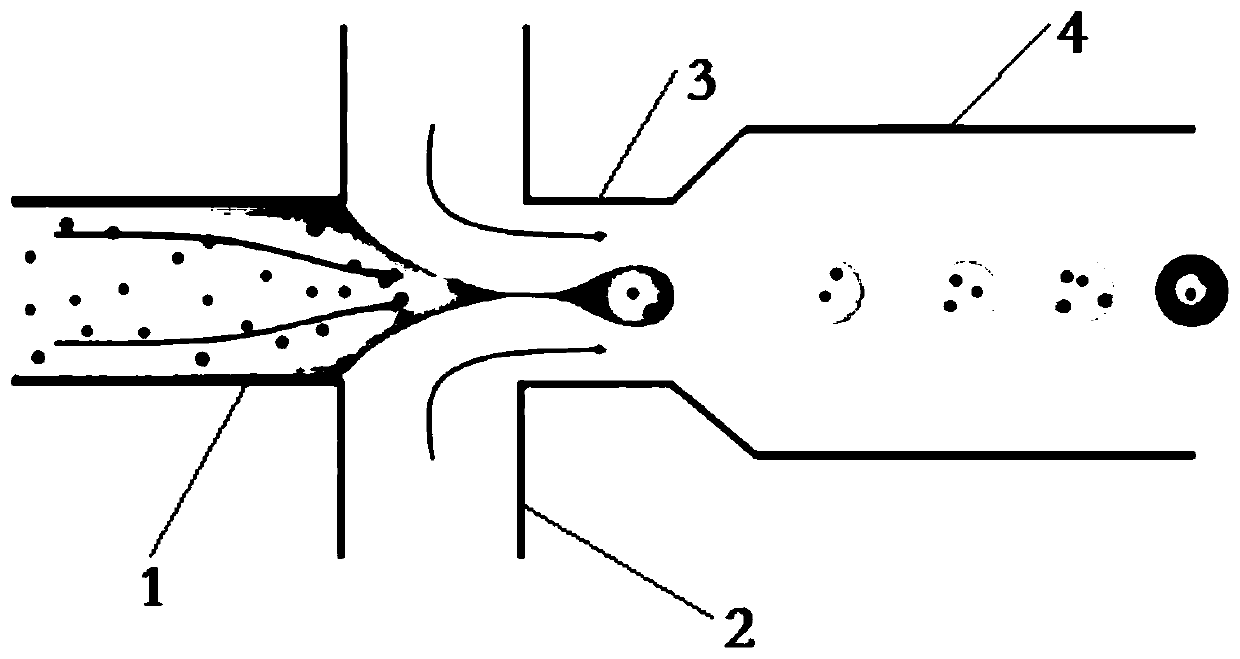

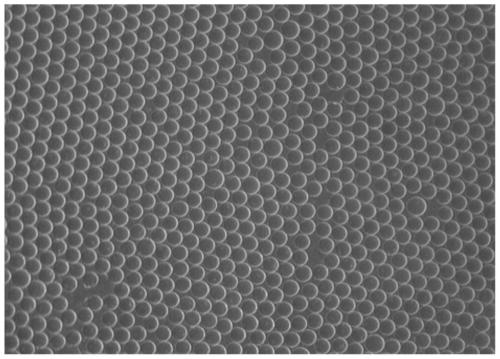

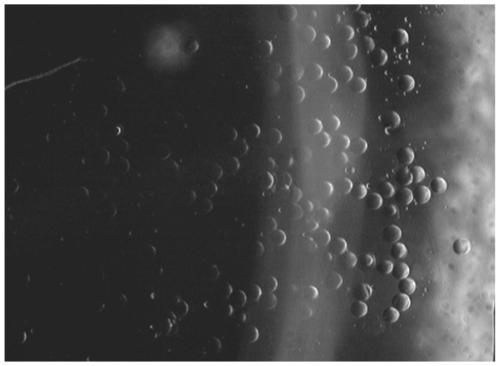

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a method for preparing composite gel microspheres, wherein the composite gel microspheres are composite gel microspheres of silk fibroin and collagen, and the preparation method specifically includes the following steps:

[0051] S1, modifying the silk fibroin to obtain a methacrylic anhydride-treated silk fibroin solution

[0052] (1) Add 5 g of degummed silk to a 9.3 M lithium bromide solution for dissolution, heat treatment at 60° C. for 1 hour, and prepare a silk fibroin solution;

[0053] (2) Add 1.5ml of glycidyl methacrylate to the silk fibroin solution, stir at a speed of 3000rpm to mix the solution evenly, and then heat treatment at 60°C for 4h to obtain methacrylic acid anhydride silk fibroin solution.

[0054] S2, adding methacrylic anhydrided collagen solution and photoinitiator to the methacrylic anhydrided silk fibroin solution to obtain a prepolymer solution

[0055] (3) Place the methacrylic anhydrided silk fibroin solution in ...

Embodiment 2

[0062] This embodiment provides a method for preparing composite gel microspheres, wherein the composite gel microspheres are composite gel microspheres of silk fibroin and hyaluronic acid, and the preparation method specifically includes the following steps:

[0063] S1, modifying the silk fibroin to obtain a methacrylic anhydride-treated silk fibroin solution

[0064] (1) Add 5 g of degummed silk to a 9.3 M lithium bromide solution for dissolution, heat treatment at 60° C. for 1 hour, and prepare a silk fibroin solution;

[0065] (2) Add 2.25ml glycidyl methacrylate to the silk fibroin solution, stir at a speed of 3000rpm to mix the solution evenly, and then heat treatment at 60°C for 4h to obtain methacrylic acid anhydride silk fibroin solution.

[0066] S2, adding hyaluronic acid solution and photoinitiator of methacrylic anhydride to the silk fibroin solution of methacrylic anhydride to obtain prepolymer solution

[0067] (3) Place the methacrylic anhydrided silk fibroi...

Embodiment 3

[0074] This embodiment provides a method for preparing composite gel microspheres, wherein the composite gel microspheres are composite gel microspheres of silk fibroin and gelatin, and the preparation method specifically includes the following steps:

[0075] S1, modifying the silk fibroin to obtain a methacrylic anhydride-treated silk fibroin solution

[0076] (1) Add 5 g of degummed silk to a 9.3 M lithium bromide solution for dissolution, heat treatment at 60° C. for 1 hour, and prepare a silk fibroin solution;

[0077] (2) Add 1.5ml of glycidyl methacrylate to the silk fibroin solution, stir at a speed of 3000rpm to mix the solution evenly, and then heat treatment at 60°C for 4h to obtain methacrylic acid anhydride silk fibroin solution.

[0078] S2, adding methacrylic anhydrided gelatin solution and photoinitiator to the methacrylic anhydrided silk fibroin solution to obtain a prepolymer solution

[0079] (3) Place the methacrylic anhydrided silk fibroin solution in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com