Fiber-reinforced heat-insulating silicone aerogel composite material and preparation method thereof

A composite material and fiber-reinforced technology, which is applied in the field of organosilicon airgel thermal insulation composite materials and its preparation, can solve the problems of unreported material thermal insulation performance and cumbersome steps, and achieve strong machinability, simple preparation process, The effect of low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh a certain amount of urea and acetic acid (5mmol / L) respectively, add them to the reaction kettle, stir mechanically until they are completely dissolved, then add MTMS (methyltrimethoxysilane), DMDMS (dimethyldimethoxy Silane) and CTAC (cetyltrimethylammonium chloride) were vigorously stirred for 0.5-1h to obtain a silicone solution. The mass ratio of urea, acetic acid (5mmol / L), MTMS, DMDMS and CTAC is 14.41:43.21:11.44:1.93:2.27.

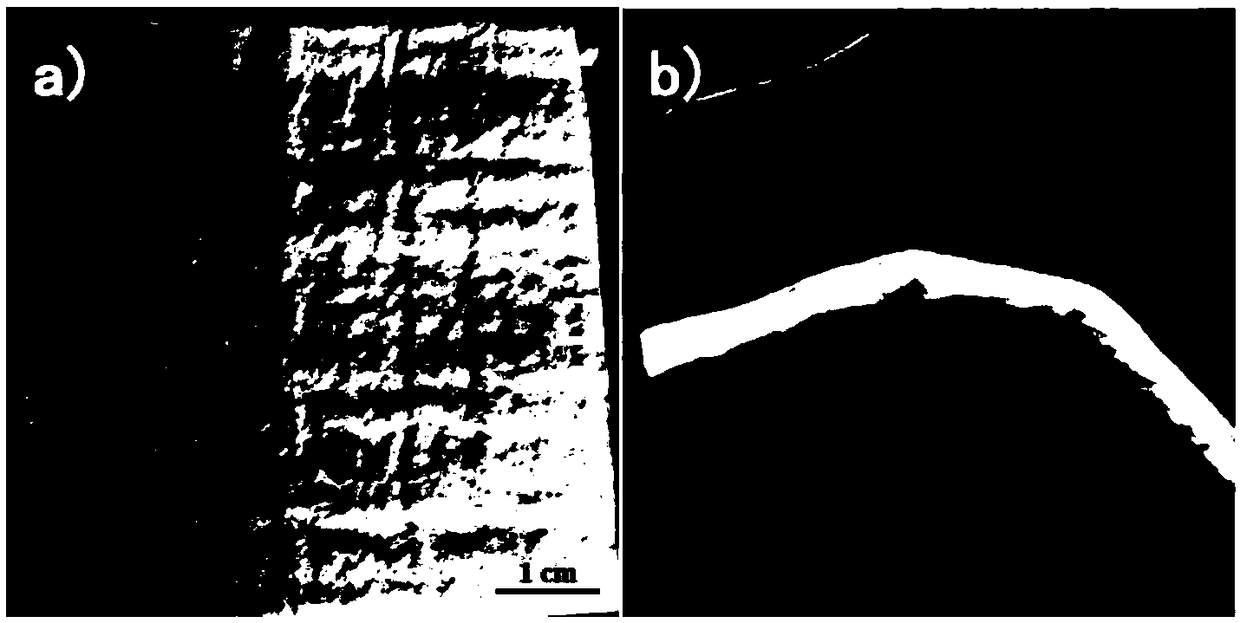

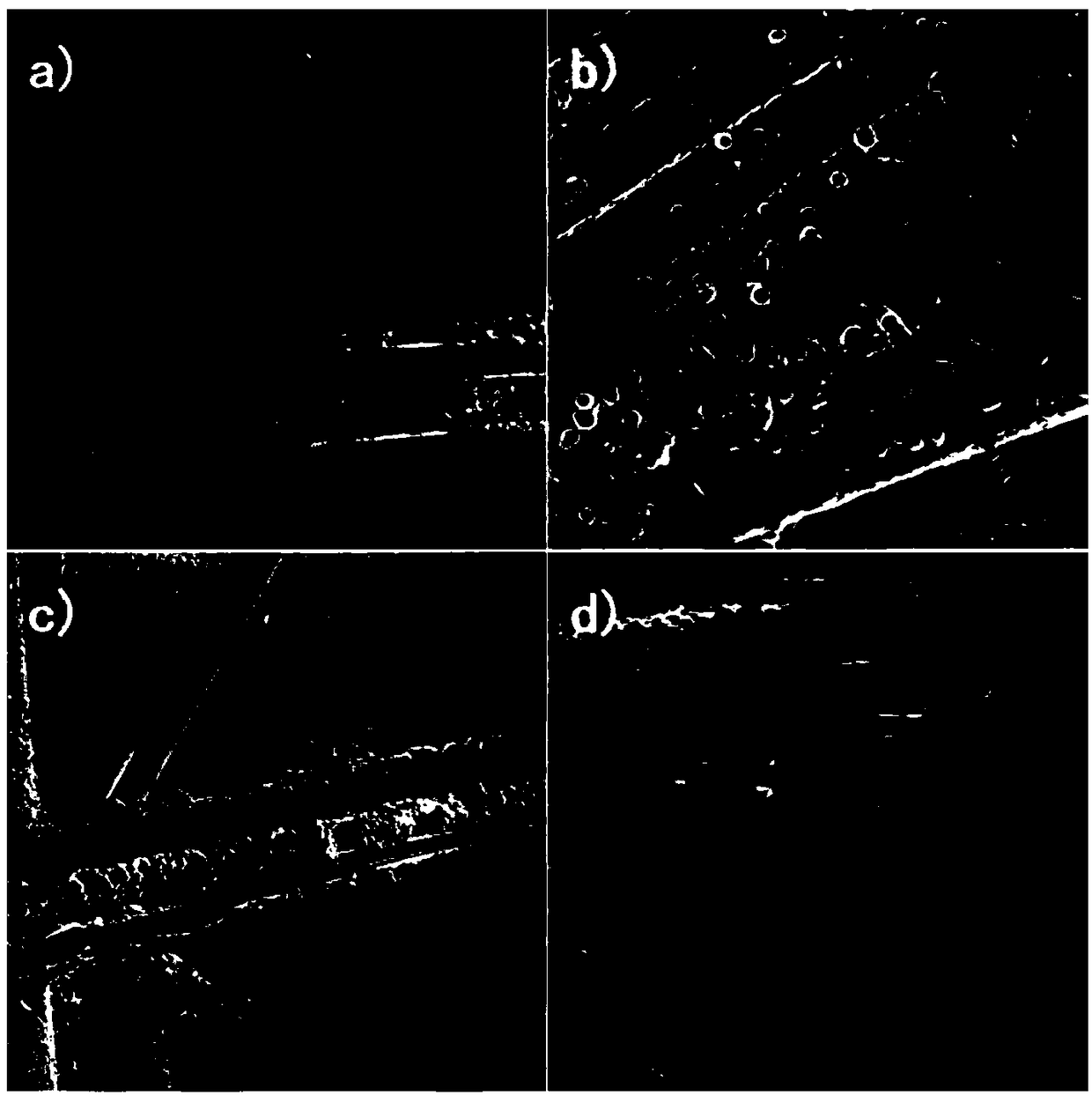

[0029] Set the density to 170Kg / m 3 The quartz needle-punched fiber mat is cut into a size of 150×150mm 2 , and placed in an oven at 100°C for heat treatment for more than 6 hours; the heat-treated quartz needle-punched fiber mat was laid flat in a stainless steel mold customized in the laboratory, and the above-mentioned organosilicon solution was used to slowly impregnate the quartz needle-punched fiber at normal temperature and pressure. Felt until the silicone impregnating solution can completely infiltrate, then seal the mold, p...

Embodiment 2

[0031] Weigh a certain amount of urea and acetic acid (5mmol / L) respectively, add them into the reaction kettle, stir mechanically until they are completely dissolved, then add MTMS, DMDMS and CTAC in turn and stir vigorously for 0.5-1h to obtain a silicone solution. The mass ratio of urea, acetic acid (5 mmol / L), MTMS, DMDMS, and CTAC is 14.41:43.21:10.18:2.96:2.27.

[0032] Set the density to 170Kg / m 3 The quartz needle-punched fiber mat is cut into a size of 150×150mm 2 , and placed in an oven at 100°C for heat treatment for more than 6 hours; the heat-treated quartz needle-punched fiber mat was laid flat in a stainless steel mold customized in the laboratory, and the above-mentioned organosilicon solution was used to slowly impregnate the quartz needle-punched fiber at normal temperature and pressure. Felt until the silicone impregnating solution can completely infiltrate, then seal the mold, place it in an oven at 80°C, and undergo 12h of sol-gel reaction and aging moldi...

Embodiment 3

[0034] Weigh a certain amount of urea and acetic acid (5mmol / L) respectively, add them into the reaction kettle, stir mechanically until they are completely dissolved, then add MTMS, DMDMS and CTAC in turn and stir vigorously for 0.5-1h to obtain a silicone solution. The mass ratio of urea, acetic acid (5 mmol / L), MTMS, DMDMS, and CTAC is 14.41:43.21:10.18:2.96:2.27.

[0035] Set the density to 120Kg / m 3 The glass fiber mat is cut into a size of 150×150mm 2 , and placed in an oven at 100°C for heat treatment for more than 6 hours; the heat-treated quartz needle-punched fiber mat was laid flat in a stainless steel mold customized in the laboratory, and the above-mentioned organosilicon solution was used to slowly impregnate the quartz needle-punched fiber at normal temperature and pressure. Felt, until the silicone impregnating liquid can be completely infiltrated, then seal the mold, place it in an oven at 80°C, undergo 12h of sol-gel reaction, aging and molding; Wash 3 time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com