Brazing filler metal-carried hard alloy block and preparation method thereof

A technology of cemented carbide block and brazing material, which is applied in metal processing equipment, welding media, manufacturing tools, etc., can solve the problems of insufficient brazing material, excessive brazing material, waste, etc., and achieve improved seam filling and high assembly accuracy , the effect of quantitative and precise addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

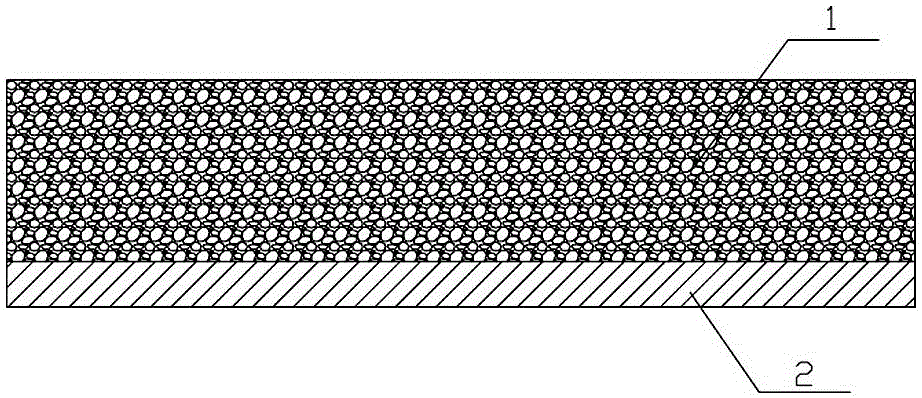

[0015] The preparation method of the cemented carbide ingot with brazing filler metal of the present invention is:

[0016] The brazing alloy is prepared into a coiled wire shape required for thermal spraying through smelting, extrusion, drawing and other processes; No oil, no impurities, no oxidation; then, the coil-shaped brazing alloy is sprayed on the to-be-welded surface of the cemented carbide block by thermal spraying equipment to form a brazing alloy layer 2 with a certain thickness. The cemented carbide block is directly assembled with the base body during welding.

Embodiment 1

[0019] The cemented carbide block is selected from YG6, the size is 20mm×20mm×10mm; the brazing alloy is BCu58ZnMn, the thickness is 0.2mm and the wire is 2.0mm in diameter; the base material is Q235 steel, the size is 20mm×20mm×20mm; Use YJ2; the brazing method is induction brazing. The first method is to spray the BCu58ZnMn wire with a diameter of 2.0mm to the surface to be welded of the cemented carbide block by thermal spraying equipment, the coating thickness is 0.2mm, and then assemble the cemented carbide block with Q235, using a high-frequency induction welding machine Welding, the flux is continuously added during the welding process until the brazing joint is formed; the second method is to cut the BCu58ZnMn strip with a thickness of 0.2mm into sheets with a size of 20mm × 20mm × 0.2mm, and the cemented carbide block, The brazing material sheet and the base body are assembled, and the same brazing process is used for brazing to form a brazing joint. The shear streng...

Embodiment 2

[0021] The cemented carbide block is selected from YG6, the size is 20mm×20mm×10mm; the brazing alloy is BAg40CuZnCd, the thickness is 0.3mm and the wire is 2.0mm in diameter; the base material is Q235 steel, the size is 20mm×20mm×20mm; the flux Use FB102; the brazing method is induction brazing. The first method is to spray the BAg40CuZnCd wire with a diameter of 2.0mm to the surface to be welded of the cemented carbide block by thermal spraying equipment, the coating thickness is 0.3mm, and then assemble the cemented carbide block with Q235, using a high-frequency induction welding machine Welding, the flux is continuously added during the welding process until the brazing joint is formed; the second method is to cut the BAg40CuZnCd strip with a thickness of 0.2mm into sheets with a size of 20mm × 20mm × 0.2mm, and the cemented carbide block, The brazing material sheet and the base body are assembled, and the same brazing process is used for brazing to form a brazing joint. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com