Variable-scale boron-nitrogen graphene modified layer brazing filler metal as well as preparation method and application thereof

A graphene modification and scale-changing technology, applied in manufacturing tools, welding equipment, metal processing equipment, etc., can solve problems such as low connection strength, low connection strength, and nitrogen loss, and achieve enhanced phase segregation , Improve the fluidity of solder and enhance the effect of filling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

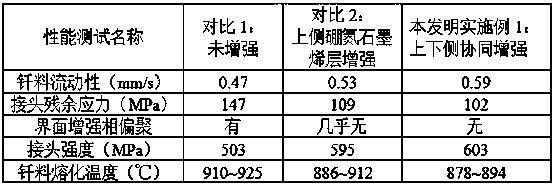

Embodiment 1

[0039] A variable-scale boron-nitrogen graphene modified layer brazing filler metal, comprising a boron-nitrogen graphene reinforced alloy layer with a thickness of 25nm on the upper surface, the boron-nitrogen graphene reinforced alloy layer is composed of boron-nitrogen graphene and nickel-based alloy Composition, the nickel-based alloy is a binary nickel-based alloy composed of nickel and gold, which can reduce the melting temperature of the brazing filler metal, improve the fluidity of the brazing filler metal, and enhance the seam filling ability of the brazing filler metal;

[0040]A silver brazing filler metal sheet located in the middle layer with a thickness of 250 μm, the silver brazing filler metal sheet is a silver-copper-nickel foil ribbon brazing filler metal with an Ag content of less than 18.5%, which has a solid solution strengthening effect and can enhance the alloy layer of boron nitride graphene. , The boron nitride graphene-coated foam metal layer is organi...

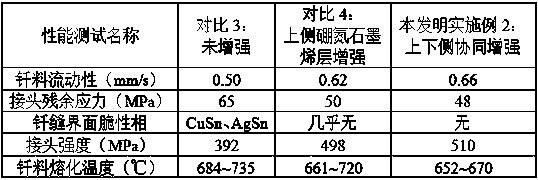

Embodiment 2

[0061] A variable-scale boron nitride graphene modified layer solder, comprising a boron nitride graphene reinforced alloy layer located on an upper surface layer and a thickness of 15 nm, and the boron nitride graphene reinforced alloy layer is composed of boron nitride graphene and nickel-based alloys. The nickel-based alloy is a ternary nickel-based alloy composed of nickel, gold and copper, which can reduce the melting temperature of the solder, improve the fluidity of the solder, and enhance the ability of the solder to fill gaps;

[0062] A gold brazing filler metal sheet located in the middle layer with a thickness of 80 μm, the gold brazing filler metal sheet is a gold-nickel-copper-boron foil ribbon brazing filler metal with an Au content of less than 40%, which has the effect of solid solution strengthening and can enhance the boron nitride graphene alloy. layer and boron nitride graphene-coated foam metal layer are organically fused into the brazing gap to form a hig...

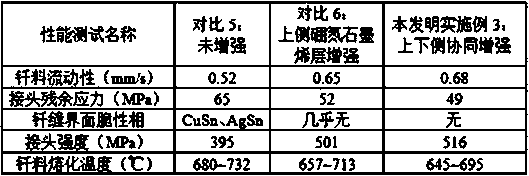

Embodiment 3

[0083] A kind of variable-scale boron-nitrogen graphene modified layer solder, comprising a boron-nitrogen graphene reinforced alloy layer with a thickness of 10nm on the upper surface, the boron-nitrogen graphene reinforced alloy layer is composed of boron-nitrogen graphene and nickel-based alloy Composition, the nickel-based alloy is a ternary nickel-based alloy composed of nickel, gold and copper, which can reduce the melting temperature of the brazing filler metal, improve the fluidity of the brazing filler metal, and enhance the seam filling ability of the brazing filler metal;

[0084] A gold brazing filler metal sheet with a thickness of 100 μm located in the middle layer. The gold brazing filler metal sheet is a gold-nickel-copper-boron foil strip solder with an Au content of less than 40%, which has a solid solution strengthening effect and can strengthen the boron-nitrogen-graphene alloy Layer, boron-nitrogen graphene-coated metal foam layer is organically fused into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com