Brazing flux solution and application thereof

A flux and solution technology, used in welding media, welding/cutting media/materials, metal processing equipment, etc., can solve the problems of low welding qualification rate and high requirements for parts and components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

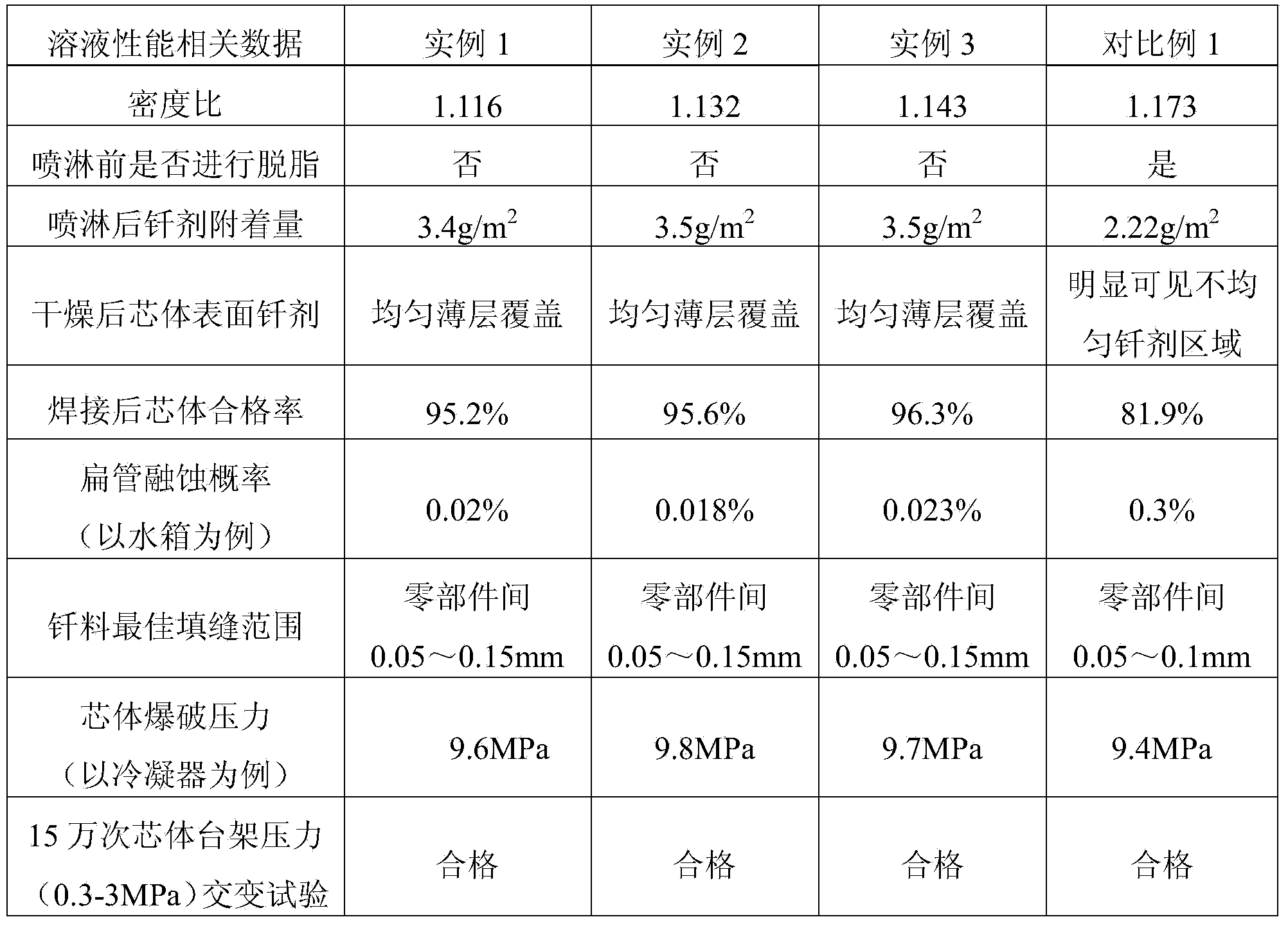

Examples

Embodiment 1

[0030] The flux solution contains:

[0031] Flux (FLUX): 16 parts by weight;

[0032] (Manufacturer: Beijing Sianke Technology Co., Ltd., product number: T300055)

[0033] Flux additive (HNM-W100): 10 parts by weight;

[0034] (Manufacturer: Beijing Sianke Technology Co., Ltd., product number: HNM-W100)

[0035] Functional additive (HAOM-N100): 1.6 parts by weight;

[0036] (Manufacturer: Beijing Sianke Technology Co., Ltd., product number: HAOM-N100)

[0037] Deionized water: 72.4 parts by weight.

Embodiment 2

[0039] The flux solution contains:

[0040] Flux (FLUX): 18 parts by weight;

[0041] (Manufacturer: Beijing Sianke Technology Co., Ltd., product number: T300055)

[0042] Flux additive (HNM-W100): 10 parts by weight;

[0043] (Manufacturer: Beijing Sianke Technology Co., Ltd., product number: HNM-W100)

[0044]Functional additive (HAOM-N100): 1.8 parts by weight;

[0045] (Manufacturer: Beijing Sianke Technology Co., Ltd., product number: HAOM-N100)

[0046] Deionized water: 70.2 parts by weight.

Embodiment 3

[0048] The flux solution contains:

[0049] Flux (FLUX): 20 parts by weight;

[0050] (Manufacturer: Beijing Sianke Technology Co., Ltd., product number: T300055)

[0051] Flux additive (HNM-W100): 10 parts by weight;

[0052] (Manufacturer: Beijing Sianke Technology Co., Ltd., product number: HNM-W100)

[0053] Functional additive (HAOM-N100): 2 parts by weight;

[0054] (Manufacturer: Beijing Sianke Technology Co., Ltd., product number: HAOM-N100)

[0055] Deionized water: 68 parts by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com