Amorphous foil brazing filler metal for ceramic braze welding

An amorphous foil and brazing technology, applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., can solve the problems of uniformity influence, easy formation of segregation and pores, etc., and achieve easy assembly and welding, composition Uniform, good flexibility effect

Inactive Publication Date: 2012-12-12

GUANGDONG PROVINCIAL INST OF WELDING TECH GUANGDONG PROVINCIAL ACADEMY OF UKRAINE

View PDF6 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Foil-shaped solder can be rolled into composite solder foil strips by using pure nickel plate, red copper plate and pure titanium plate, but the uniformity of each component of the composite solder foil strip prepared by this method is affected during the brazing thermal cycle , easy to form defects such as segregation and pores

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

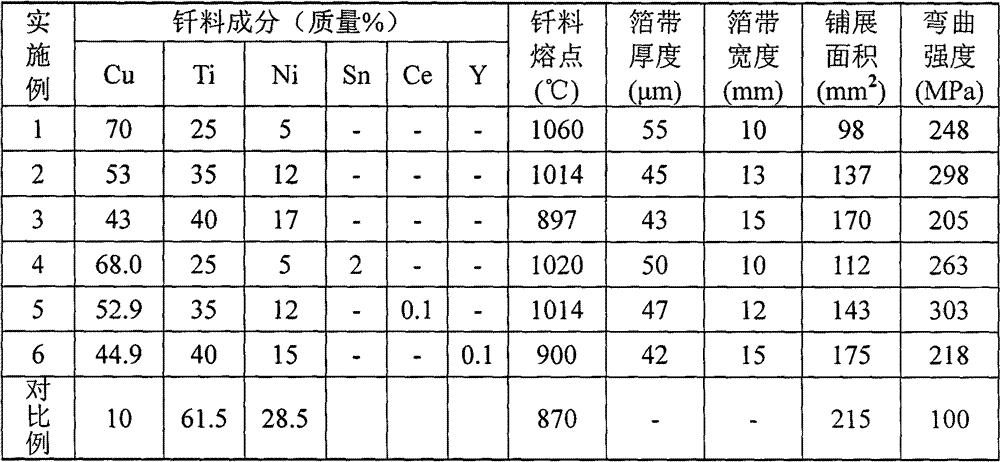

[0019] The composition and mass percentage of solder are Cu70%, Ti25%, Ni5%.

Embodiment 2

[0021] The composition and mass percentage of solder are Cu53%, Ti35%, Nil2%.

Embodiment 3

[0023] The composition and mass percentage of solder are Cu43%, Ti40%, Ni17%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

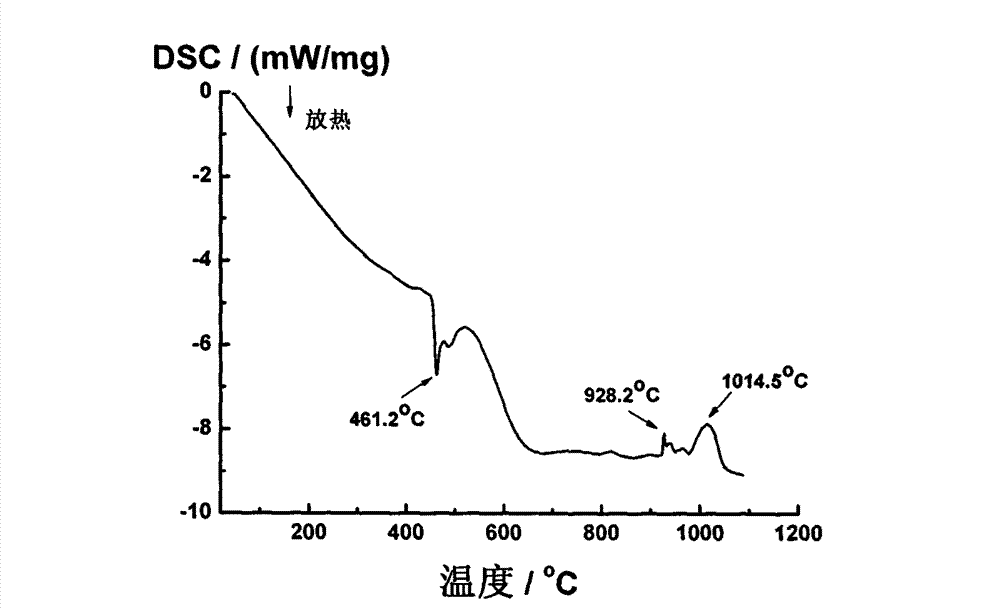

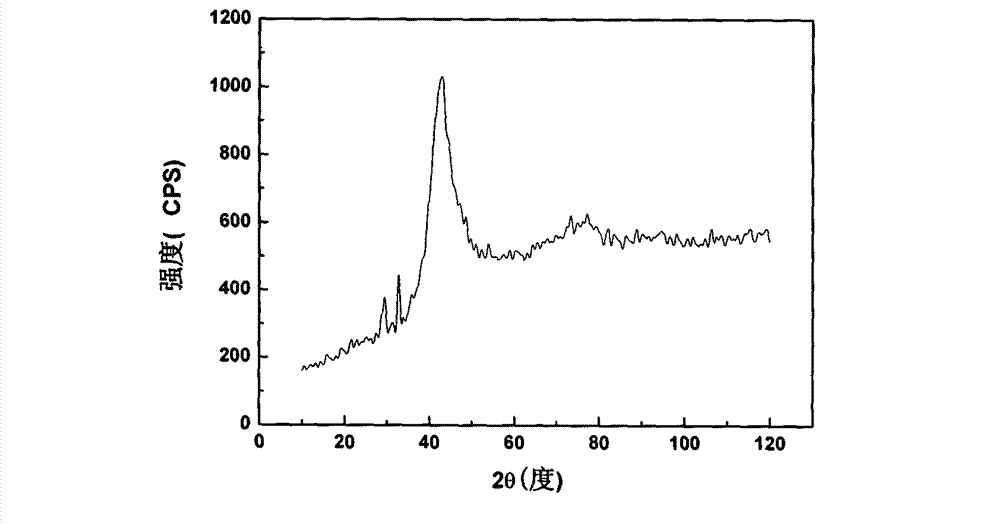

The invention relates to an amorphous foil brazing filler metal for ceramic braze welding. The amorphous foil brazing filler metal for ceramic braze welding is characterized by comprising following components according to mass percent: 43-70% of Cu, 25-40% of Ti and 5-17% of Ni, and further comprising 0.1-2% of Sn, Ce or Y. The brazing filler metal, provided by the invention, is the amorphous foil brazing filler metal which is easily assembled and welded and free of expensive Ag metal. The brazing filler metal has ductility, so that the fragility of crystalline brazing filler metal is avoided, and the brazing filler metal is easily assembled and shimmed when a complicated structure is subjected to braze welding. The melting range of the brazing filler metal is 895-1060 DEG C, the temperature of braze welding is 950-1100 DEG C, and the amorphous foil brazing filler metal is suitable for vacuum brazing of ceramic / ceramic or ceramic / metal.

Description

technical field [0001] The invention relates to a solder for brazing, in particular to a solder for ceramic brazing. Background technique [0002] Ceramics have excellent high-temperature mechanical properties, corrosion resistance, and wear resistance. They are used as key components of heat engines and have broad application prospects in the manufacture of internal combustion engines and heat exchangers. Active brazing has outstanding advantages in the connection of ceramics and ceramics, ceramics and metals. Commonly used active solders for ceramic brazing include Ag-Cu-Ti, Ti-Ni-Cu, etc. Composed of Ag 69 Cu 26 Ti 5 The Ag-Cu-Ti solder has a brazing temperature of 850-880 ° C, good wettability to ceramics, airtight joints, and joint strength of 60-100 MPa, but the solder contains a large amount of Ag, high cost, and Ag is anti-oxidant Poor, the use temperature of the workpiece after brazing is low, which limits the excellent high temperature performance of ceramics....

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K35/34

Inventor 房卫萍刘凤美易耀勇郑世达刘正林刘师田邓振华

Owner GUANGDONG PROVINCIAL INST OF WELDING TECH GUANGDONG PROVINCIAL ACADEMY OF UKRAINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com