Wetting pilot strip-shaped brazing filler metal and preparation method thereof

A strip brazing filler metal and brazing filler metal technology are applied in the field of brazing filler metals, which can solve the problems of easy brittleness, low Sn content of AgCuZnSn brazing filler metals, reduced plasticity, etc. simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation method of the wetting leading strip solder of the present invention is as follows:

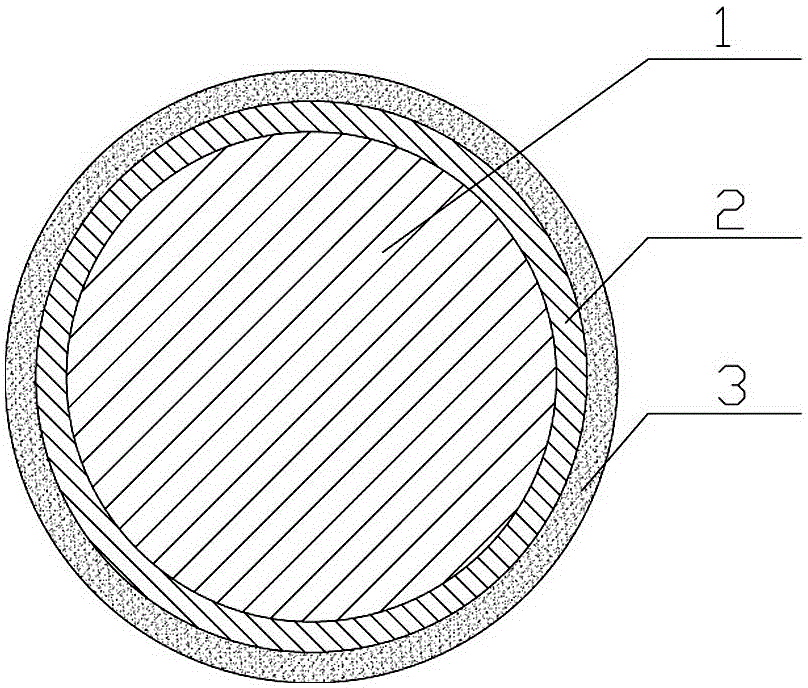

[0018] First of all, the solder alloy is prepared into filaments of the required size through smelting, extrusion, drawing and other processes. During the preparation process, the solder wire must undergo strict degreasing and pickling processes to ensure that the solder wire before hot-dip plating No oil, no impurities, no oxidation; then put the solder wire into the tinning machine for hot-dip plating. After tinning, the welding wire is prepared into a straight strip with a length of 500mm through straightening and cutting processes, and then the flux is coated on the surface of the tin layer in the form of pressure coating to form a self-contained solder wire with excellent wettability, seam filling and formability. The wetting of the flux leads to the finished strip of solder.

Embodiment 1

[0021] The brazing material alloy is BAg25CuZn wire with a diameter of 2mm, and the surface of the wire is hot-dip tinned by hot-dip plating. The thickness of the tin layer is 0.01mm. The adhesive is organic, and the thickness of the flux layer is 0.2mm. According to the national standard GB / T 11364-2008 "Solder Wettability Test Method", the matrix solder and the prepared solder were subjected to a wettability comparison test. Place 200 mg of the prepared brazing material in the center of a Q235 carbon steel plate with a thickness of 40 mm × 40 mm and a thickness of 2 mm, and cover the base solder with FB102 flux of the same quality as the prepared solder. The weight of the solder plus the base solder is 200 mg. 40mm×40mm, the center of Q235 carbon steel plate with a thickness of 2mm. Put them into the RSL-5 wetting furnace and heat them respectively, keep warm for 40-50 s after the solder is melted, and clean it after natural cooling at room temperature. After calculation, t...

Embodiment 2

[0023] The solder alloy is BAg30CuZn wire with a diameter of 2mm, and the surface of the wire is hot-dip tinned by hot-dip plating. The thickness of the tin layer is 0.02mm. The adhesive is organic, and the thickness of the flux layer is 0.2mm. According to the national standard GB / T 11364-2008 "Solder Wettability Test Method", the matrix solder and the prepared solder were subjected to a wettability comparison test. Place 200 mg of the prepared brazing material in the center of a Q235 carbon steel plate with a thickness of 40 mm × 40 mm and a thickness of 2 mm, and cover the base solder with FB102 flux of the same quality as the prepared solder. The weight of the solder plus the base solder is 200 mg. 40mm×40mm, the center of Q235 carbon steel plate with a thickness of 2mm. Put them into the RSL-5 wetting furnace and heat them respectively. After the solder is melted, keep it warm for 40-50 s. After cooling at room temperature, clean it. The wetted area of the prepared sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com