Easy-to-tidy material sticking machine for neodymium iron boron production

A sticking machine, NdFeB technology, which is used in devices for coating liquid on the surface, inductance/transformer/magnet manufacturing, permanent magnet manufacturing, etc. stacking together etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

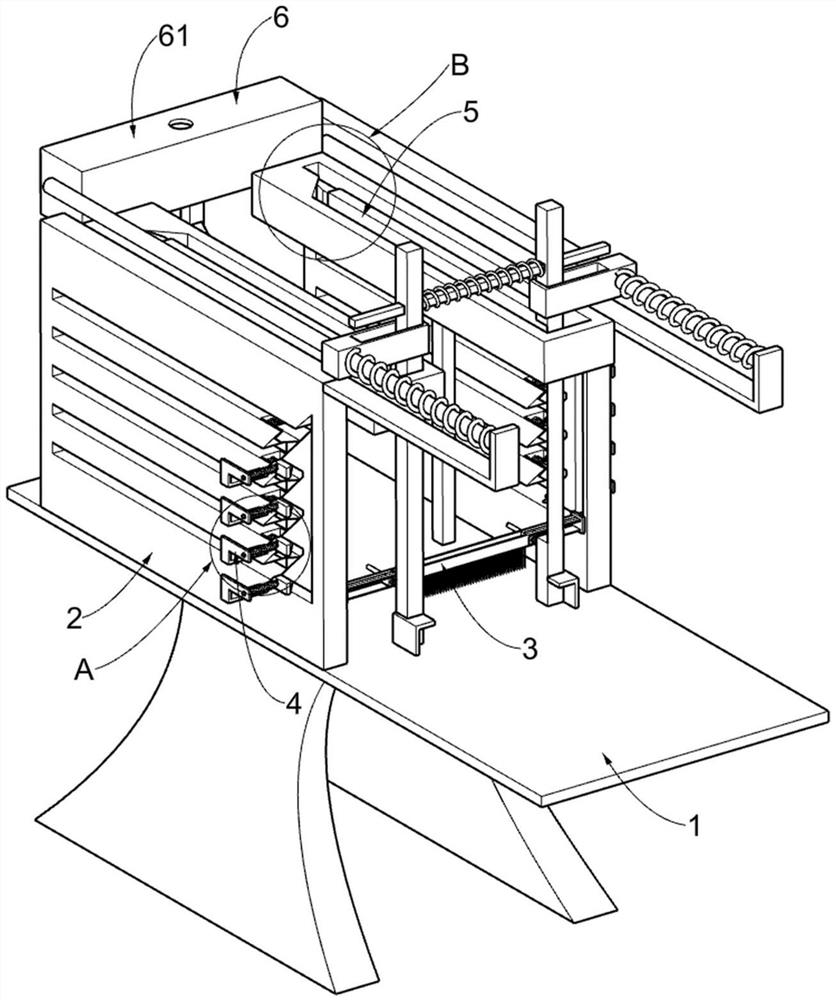

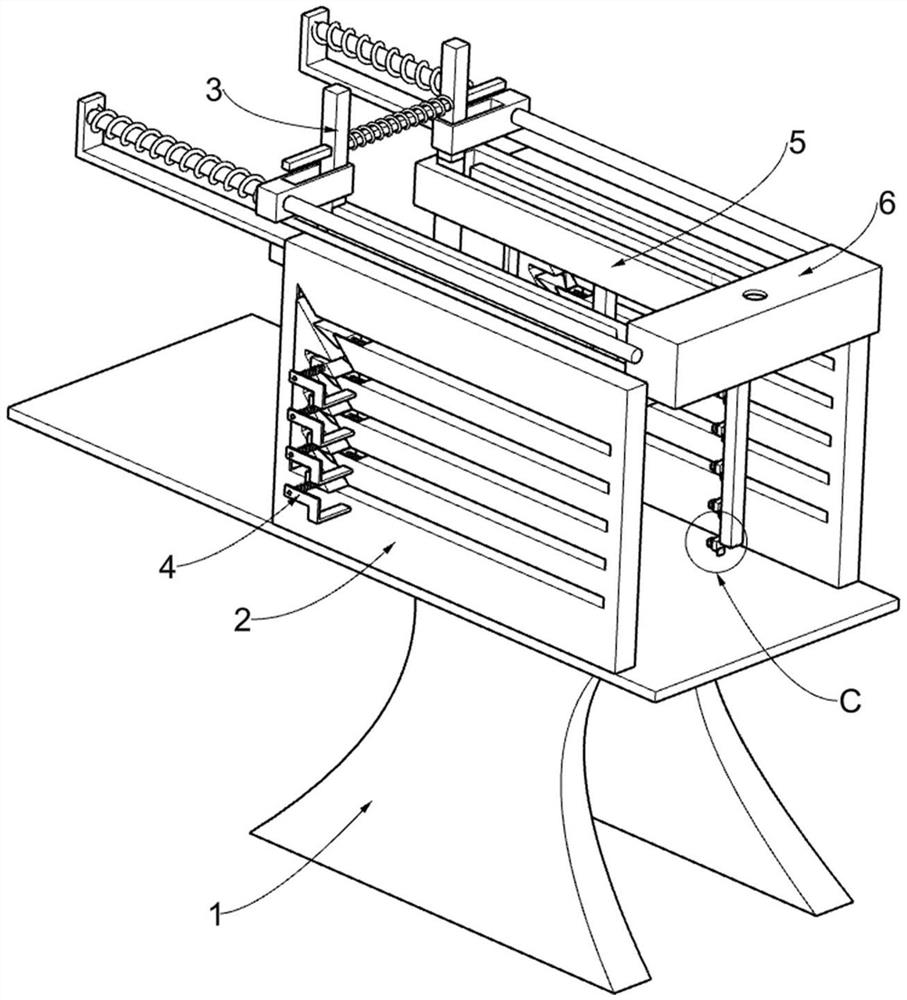

[0026] An easy-to-finish bonding machine for NdFeB production, such as Figure 1-9 As shown, it includes a fixed support frame 1, a reset mechanism 2, a glue brush mechanism 3, a lifting mechanism 4 and a guide mechanism 5, the reset mechanism 2 is located on the fixed support frame 1, and the glue brush mechanism 3 is located on the reset mechanism 2. The glue mechanism 3 is used to glue the surface of the NdFeB that needs to be glued. The lifting mechanism 4 is arranged on the reset mechanism 2, and the guide mechanism 5 is arranged on the reset mechanism 2.

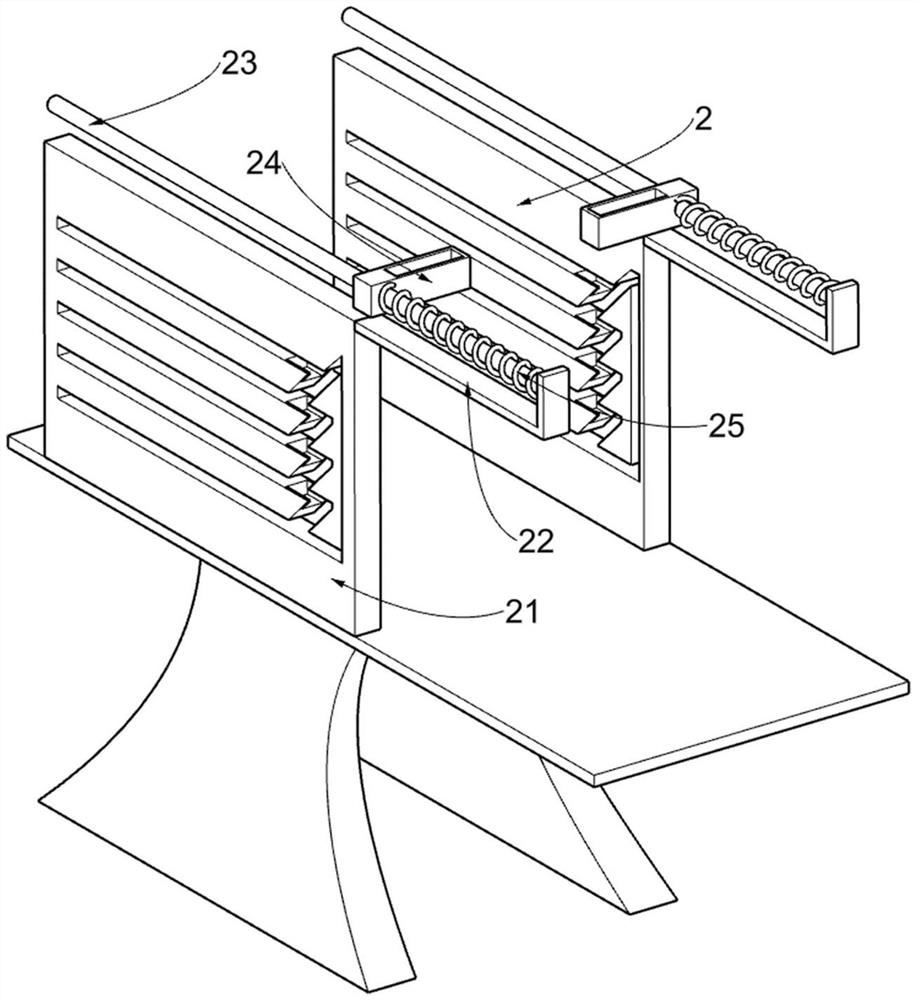

[0027] Reset mechanism 2 comprises first fixed mount 21, second fixed mount 22, first fixed rod 23, slide block 24 and first return spring 25, is provided with first fixed mount 21 symmetrically on the fixed support frame 1, and second fixed mount The frame 22 is arranged on the first fixed frame 21, the first fixed rod 23 is arranged on the second fixed frame 22, the sliding block 24 is slidably fitted on the first fi...

Embodiment 2

[0036] On the basis of Example 1, such as Figure 9 As shown, it also includes a glue adding mechanism 6, the glue adding mechanism 6 is arranged on the reset mechanism 2, the glue adding mechanism 6 is used to make the glue in the deflector block 63 flow to the brush 38, the glue adding mechanism 6 includes a fixed frame 61. Hollow tube 62, deflector block 63, sliding frame 64 and the seventh return spring 65, two first fixed frames 21 are jointly fixedly connected with fixed frame 61, fixed frame 61 contacts with fixed guide frame 51, fixed frame 61 A hollow tube 62 is fixedly connected to the top, and five guide blocks 63 are fixedly connected to the hollow tube 62 in a distributed manner. The guide block 63 is slidably equipped with a sliding frame 64, and the sliding frame 64 is used to move Glue is blocked, and the sliding frame 64 is connected with a seventh return spring 65 , the other end of the seventh return spring 65 is connected with the guide block 63 , and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com