Spinnable fiber production system for regeneration of waste clothes and method thereof

A production system, waste technology, used in fiber processing, decomposition of fiber-containing substances, textiles and papermaking, etc., can solve the problems of loss, slow cutting speed, affecting air quality, etc., to achieve the effect of ingenious design and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are preferred embodiments of the present invention, but the protection scope of the present invention is not limited thereby.

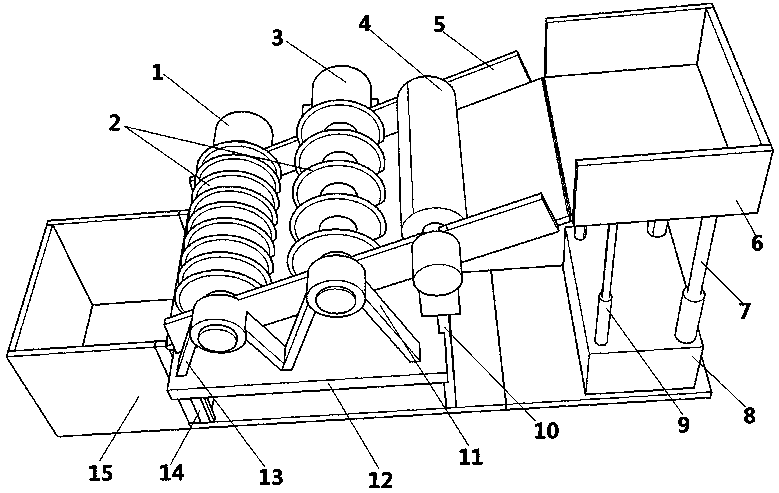

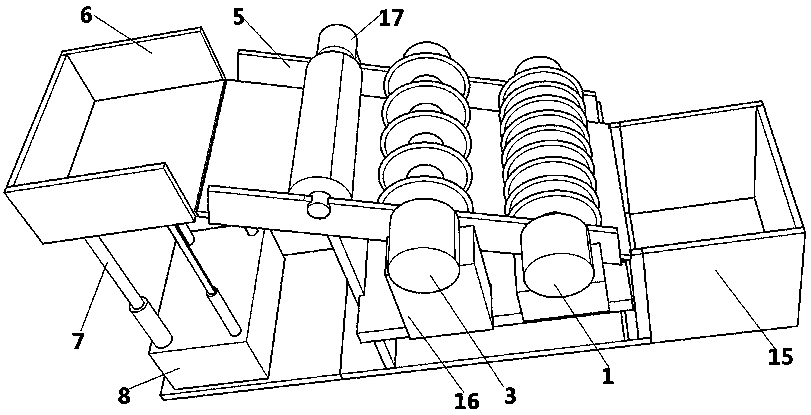

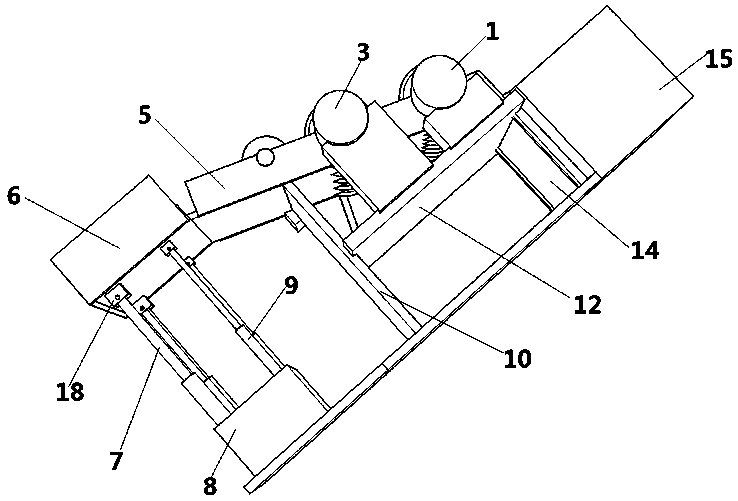

[0024] As shown in the figure, a system for producing spinnable fiber regenerated from waste and old clothes includes a first driving motor 1, a cutting device 2, a second driving motor 3, an inclined slide plate groove 5, a feeding chute 6, a first telescopic rod 7, a second Two telescopic rods 9; it is characterized in that: the ironing cylinder 4, the cutting device 2, and another cutting device 2 are sequentially installed on the inclined slide plate groove 5 from top to bottom, wherein the number of cutting knives 22 on the cutting device 2 is the same as that of the other The number of cutting knives 22 on each cutting device 2 is different, and others are all the same, wherein the rotating shaft of the iron cylinder 4 passes through the groove wall of the inclined slide plate groove 5, wherein one end of the rotating shaft o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com