Municipal sludge dewatering and recycling device

An urban sludge and sludge technology, which is applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problem of inconvenient removal of sludge, and achieve the advantages of convenient use of equipment and prevention of solidification. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

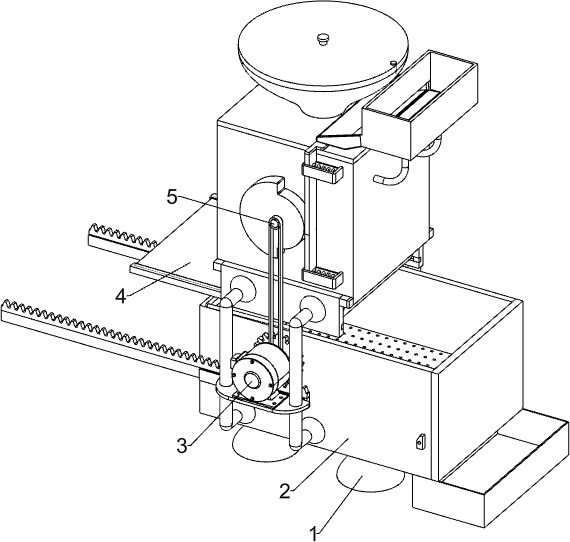

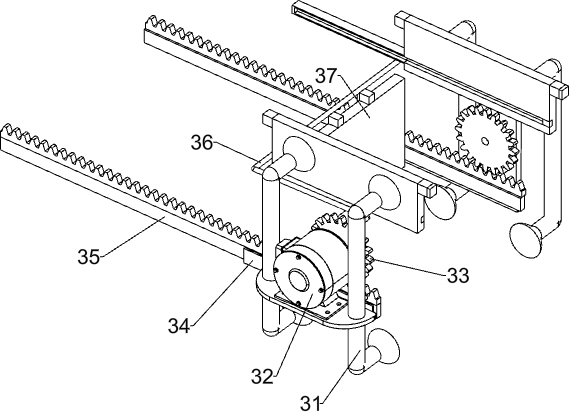

[0023] A kind of urban sludge dehydration recycling device, such as Figure 1-5 As shown, it includes a bracket 1, a dehydration container 2, an extruding assembly 3 and a discharge assembly 4. A dehydration container 2 for sludge dehydration is installed on the top of the bracket 1, and an extruder for dehydration by extrusion is installed on the dehydration container 2. Press assembly 3, and the top of extrusion assembly 3 is equipped with a discharge assembly 4 for discharging sludge by sliding.

[0024] When it is necessary to use the device for sludge dehydration, first the sludge is poured into the discharge assembly 4, and the sludge enters the dehydration container 2 through the discharge assembly 4, and then the extrusion assembly 3 is controlled to start working, and the dehydration container 2 The sludge inside is dehydrated. At the same time, when the extrusion component 3 dehydrates the sludge, it will trigger the discharge component 4 to stop the sludge from fall...

Embodiment 2

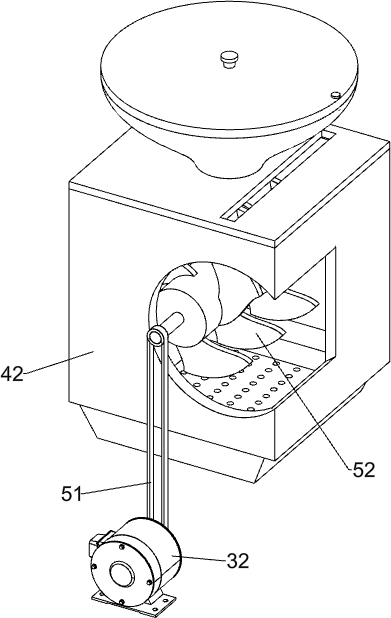

[0032] On the basis of Example 1, such as figure 1 , 6 Shown in and 7, it also includes a stirring assembly 5, the stirring assembly 5 for sludge stirring is installed in the material storage frame 42 by rotating, the stirring assembly 5 includes a transmission pulley group 51 and a stirring blade 52, and in the material storage frame 42 The central rotating type is provided with stirring blades 52 , and a transmission pulley set 51 is connected between the front end of the stirring blades 52 and the output shaft of the reduction motor 32 .

[0033] When the reduction motor 32 rotates, the transmission pulley set 51 drives the stirring blade 52 to rotate, and then the sludge is stirred, so that the sludge can be prevented from solidifying.

[0034] Also includes a blanking assembly 6, the material storage frame 42 top right side is installed with a blanking assembly 6 for blanking by sliding, the blanking assembly 6 includes a cam 61, a push plate 62, a second spring 63, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com