Automatic laying structure for road safety barrels and construction method of automatic laying structure

An anti-collision and highway technology, which is applied to roads, roads, road safety devices, etc., can solve the problems of heavy weight, broken anti-collision barrels, laborious placement of workers, etc., and achieves high speed, non-destructive and high construction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

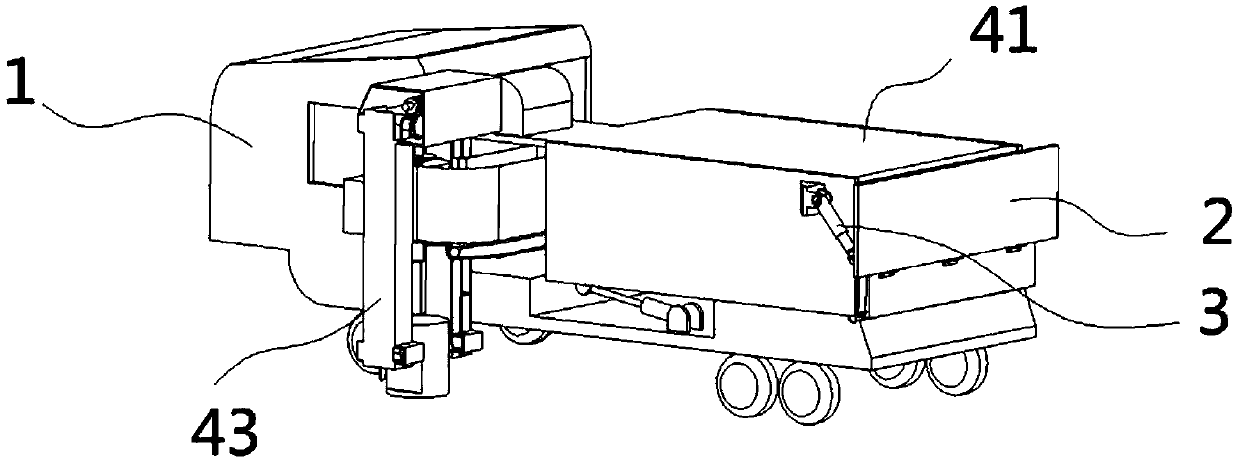

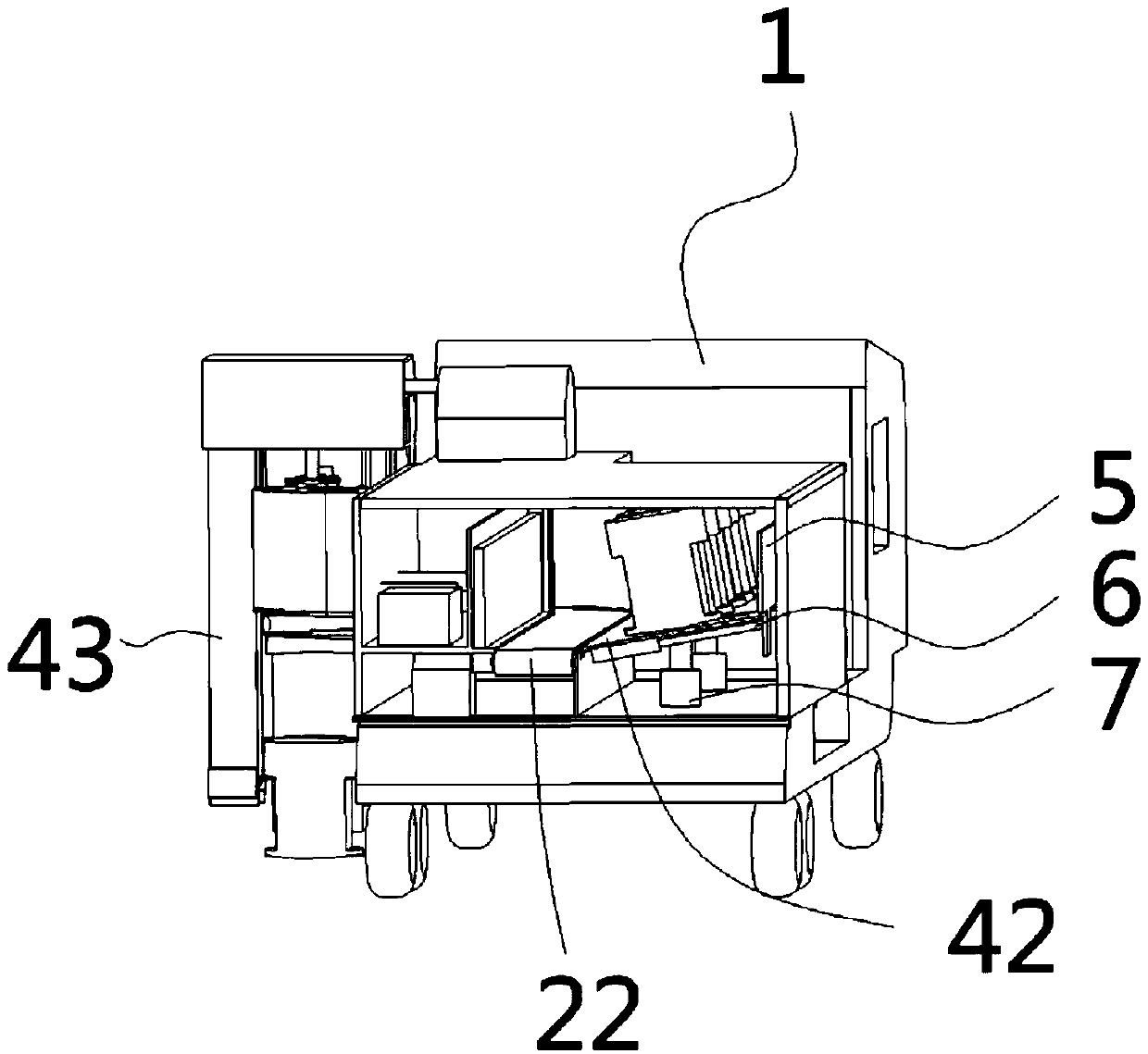

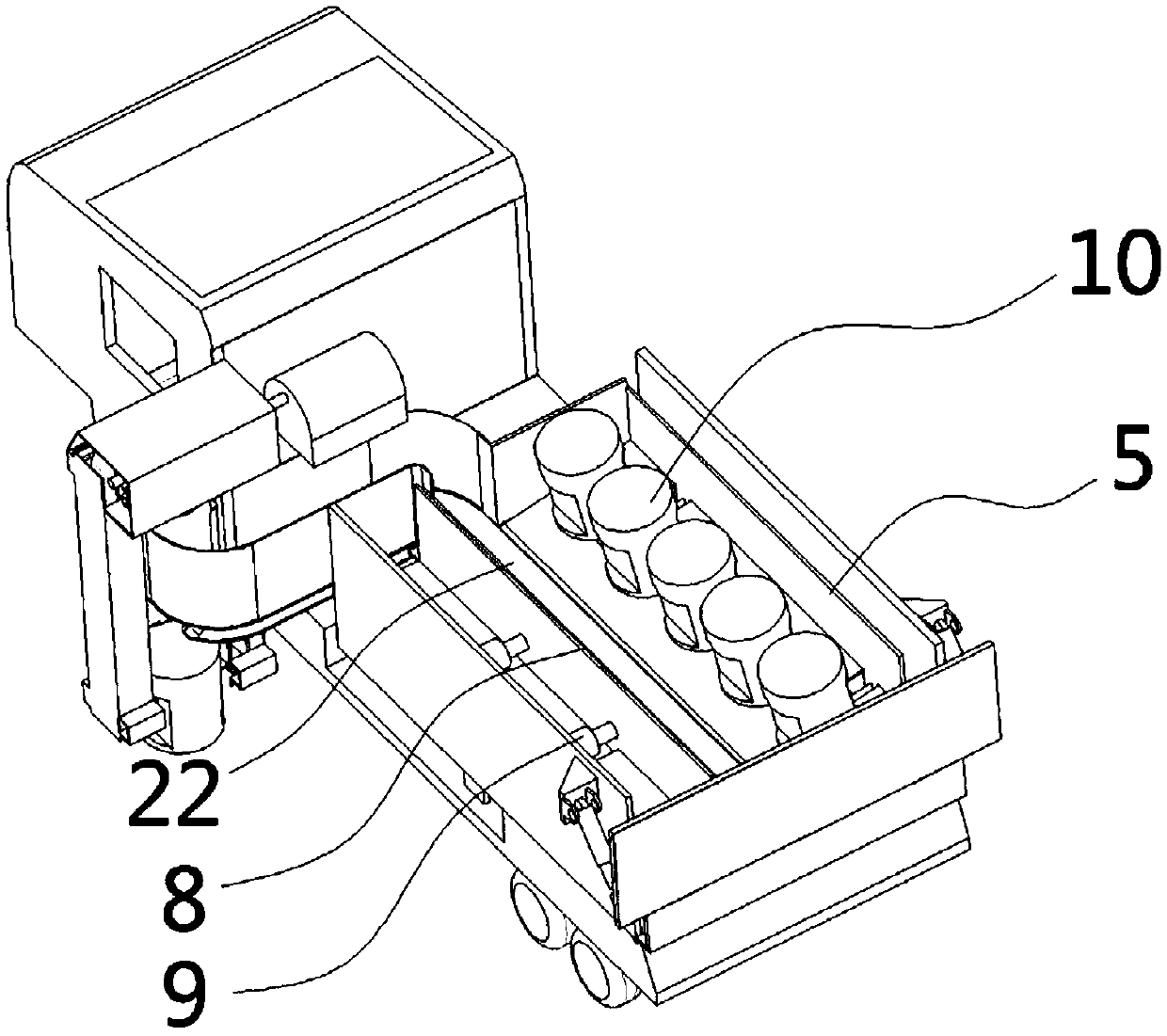

[0024] As shown in the figure, the automatic layout structure of the road anti-collision bucket includes an engineering vehicle 1, a sealing box 41 is installed on the engineering vehicle 1, and a conveyor belt 22 is installed on it, and a bottom plate 42 and a push plate are respectively installed on both sides of the conveyor belt 22. 8, wherein: the bottom plate 42 is provided with anti-collision barrels 10, and the lifting columns 7 are evenly arranged on the bottom of the bottom plate 42, and hydraulic cylinder one 6 is evenly distributed under the bottom plate 42, and the hydraulic cylinder one 6 is connected with Push pedal one 5; the rear of said push pedal 8 is connected with hydraulic cylinder two 9 and is hinged on the sealing box 41; the anti-collision bucket 10 of the present embodiment is provided with groove structure in the middle, like this in construction process, is convenient to pallet 13 Hold the anti-collision bucket 10. The feeding and discharging end of...

Embodiment 2

[0033] After the anti-collision bucket is used, in order to facilitate the recovery after use, it is not necessary for the construction personnel to carry it back to the engineering vehicle. Therefore, in order to solve this problem, a recovery mechanism is added in this embodiment.

[0034] As shown in the figure, the automatic layout structure of the road anti-collision bucket includes an engineering vehicle 1, a sealing box 41 is installed on the engineering vehicle 1, and a conveyor belt 22 is installed on it, and a bottom plate 42 and a push plate are respectively installed on both sides of the conveyor belt 22. 8, wherein: the bottom plate 42 is provided with anti-collision barrels 10, and the lifting columns 7 are evenly arranged on the bottom of the bottom plate 42, and hydraulic cylinder one 6 is evenly distributed under the bottom plate 42, and the hydraulic cylinder one 6 is connected with Push pedal one 5; the rear of said push pedal 8 is connected with hydraulic cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com