Automatic loading and unloading device, automatic assembling system and method for retaining rings and capsules

An automatic loading and unloading and automatic assembly technology, which is applied in the field of rail transit, can solve the problems of poor assembly quality and low work efficiency, and achieve the effects of easy maintenance, low cost, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

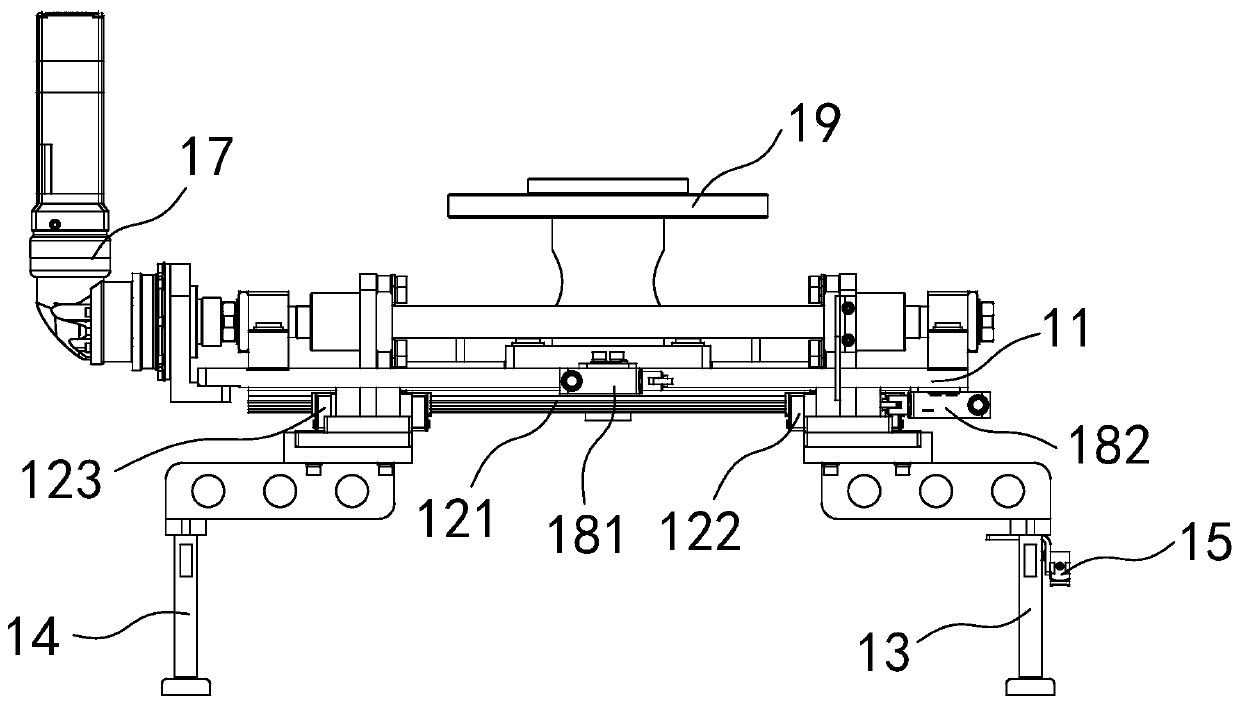

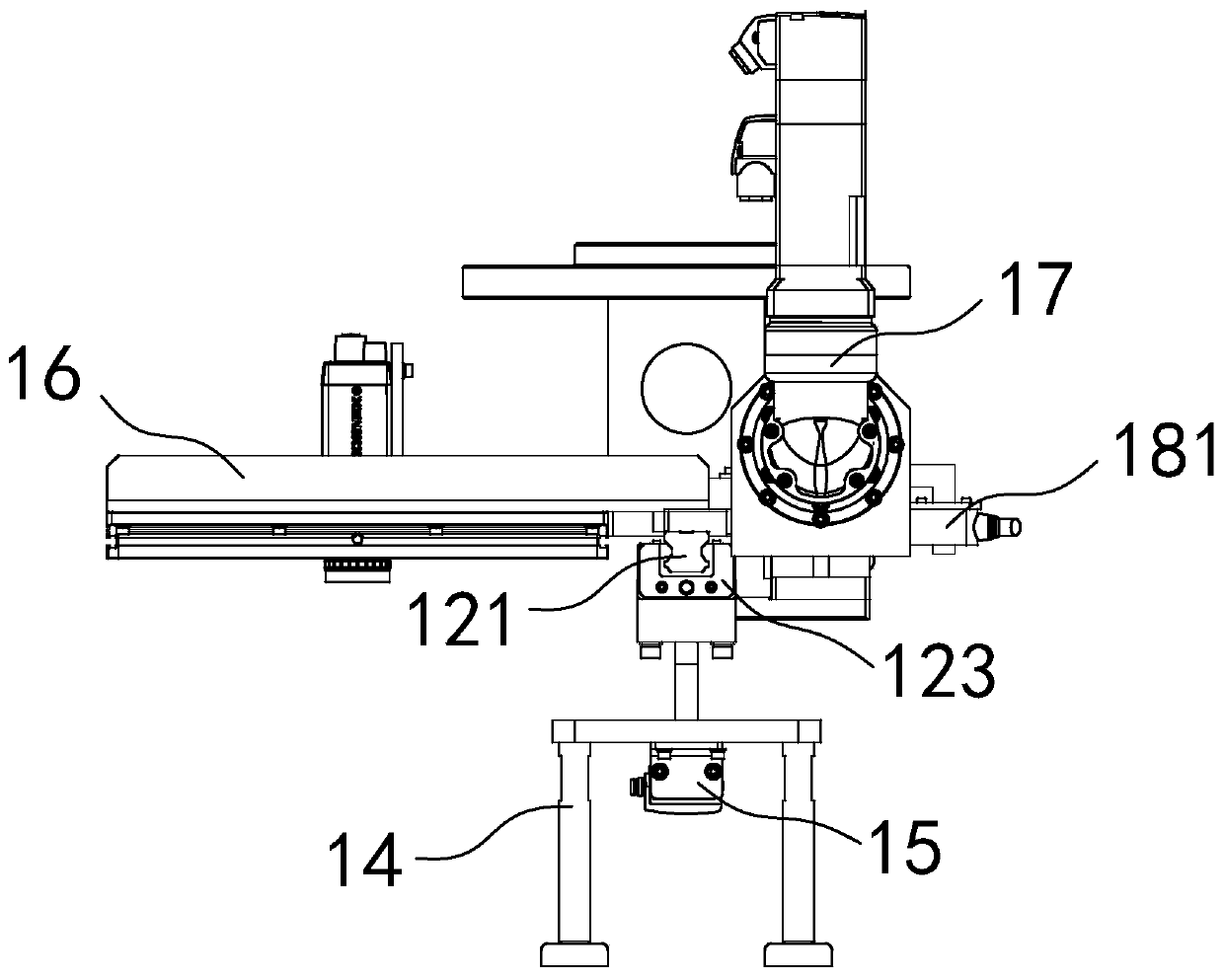

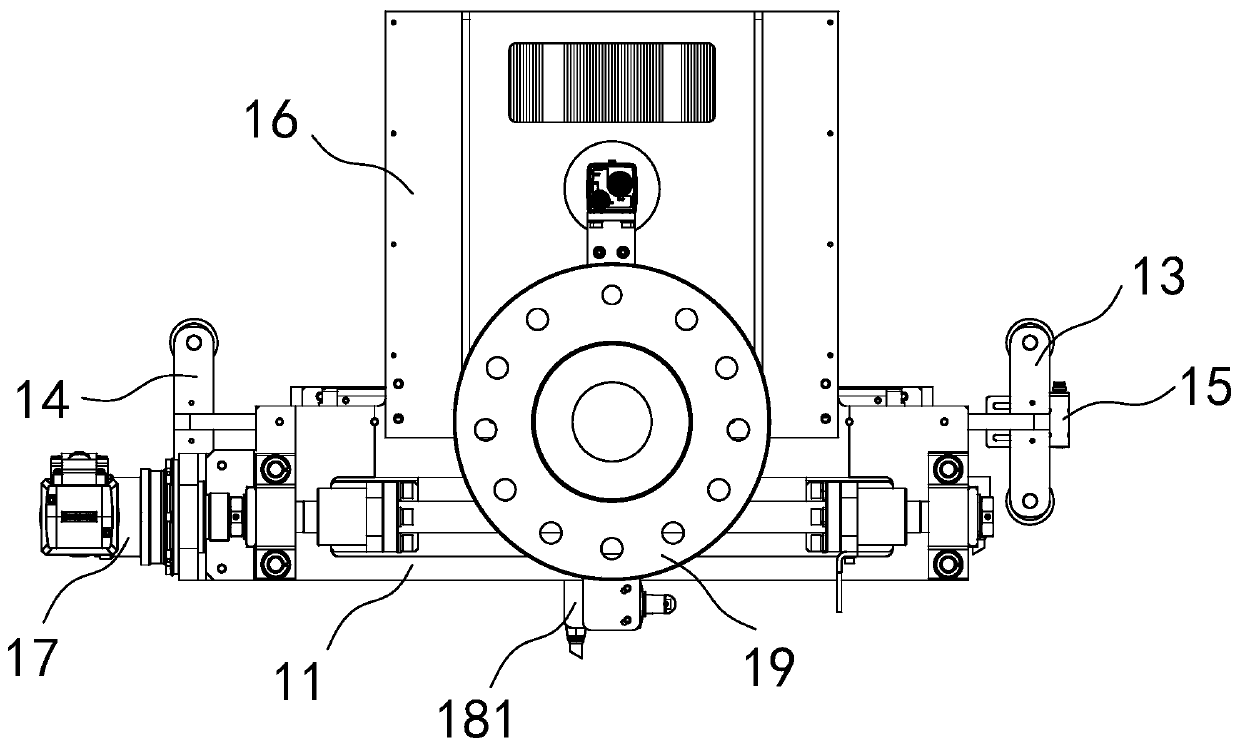

[0078] Example 1: see Figure 1 to Figure 3 , the present embodiment provides a buckle capsule automatic loading and unloading device, including:

[0079] matrix 11;

[0080] The sliding assembly includes a first fixing part 121 installed on the base 11 and a sliding part I122 and a sliding part II123 respectively slidingly connected to the first fixing part 121;

[0081] The first clamp assembly 13 is installed under the slider I122, and the first clamp assembly 13 is provided with a sensor 15 for detecting the presence or absence of the buckle and the capsule;

[0082] The second clamp assembly 14 is arranged symmetrically with the first clamp assembly 13 and installed under the slider II 123;

[0083] The visual component 16 is installed on the base 11 and is located on one side of the sliding component;

[0084] The driving assembly 17 is installed on the base body 11 and connected with the sliding part I122 and the sliding part II123.

[0085] Specifically, see Figu...

Embodiment 2

[0098] Embodiment 2: This embodiment provides an automatic assembly system for buckle capsules, including the automatic loading and unloading device for buckle capsules and the buckle capsule pressing device described in Embodiment 1. The automatic loading and unloading of the buckle and capsule is realized by the buckle capsule automatic loading and unloading device, and the automatic pressing of the buckle and capsule is realized by the buckle capsule pressing device.

[0099] The buckle capsule pressing device will be described in detail below in conjunction with the accompanying drawings. Since the structure and working process of the buckle capsule automatic loading and unloading device refer to Embodiment 1, details are not repeated here.

[0100] Specifically, see Figures 12 to 14 , Buckle Capsule Pressing Equipment, including:

[0101] The base 21 is set as a hollow structure;

[0102] The pressing mechanism 22 is installed on the bottom of the base 21 and is used ...

Embodiment 3

[0133] Embodiment 3: This embodiment provides a buckle capsule automatic assembly method, based on the buckle capsule automatic assembly system described in Embodiment 3, including the following steps:

[0134] S1. The second power mechanism works and rotates along the guide wheel mechanism, driving the second sliding assembly to slide along the second fixing part, so that the clamping block moves inward to the designated position, and puts the buckle through the buckle capsule automatic loading and unloading device. clamping block;

[0135] S2. Put the capsule on the first power mechanism through the buckle capsule automatic loading and unloading device, the first power mechanism works, and drives the guide rail linkage mechanism to move inward to squeeze the capsule; at the same time, the pressing mechanism works to rise to the set position , buckle and hold the capsule, and move the capsule down to the buckle under the action of the guide rail linkage mechanism and the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com